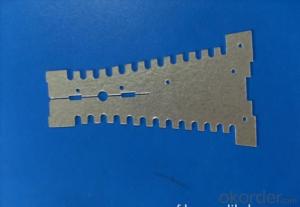

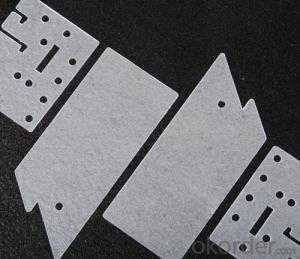

Mica Parts Used for Induction Furnace for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introductions:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: What is the electrical performance of insulating materials

- Such as the rated voltage, current, active power, reactive power, resistance, capacitance, inductance, conductance; semiconductor is famous, DC magnification, AC magnification, rectified current, reverse breakdown voltage, forward voltage , The junction voltage, the noise figure, the characteristic frequency, the cut-off frequency, the dissipation power ... the IC is also very large, the maximum working voltage, the op amp's pendulum speed, the bandwidth, the distortion coefficient, the ADC conversion rate, , The resolution of plastic in the field of electrical applications is extremely extensive, its role is mainly two aspects, one as electrical insulation materials, two for the mechanical structure of materials. These materials are used in the field of electrical engineering, mainly in the electrical, electrical and electrical industries.

- Q: What is the 8 ° C rule for insulating materials?

- The service life will be greatly shortened, such as ATR insulation material limit working temperature of 105 ℃, when the ultimate working temperature of 8, the life will be reduced by about half, which is the so-called 8 ℃ thermal deterioration rules

- Q: What kind of insulation is the insulating

- Ordinary heat conduction is made with fiberglass PP2. High thermal conductivity materials are made of thermally conductive

- Q: What type of enameled wire and insulation material is used for the compressor

- Small and medium-sized closed, semi-enclosed refrigeration compressors are used for the specific enameled wire specifically (QF) series.

- Q: What insulating material is used for high voltage cables

- Features: The rated voltage of the cable is 6kv. The long-term operating temperature of the cable is + 65 ° C. The minimum bend radius of the cable is 6 times the cable diameter.

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Such as tungsten, molybdenum, tantalum, niobium, vanadium, chromium, titanium, zirconium and other refractory metals and rare earth metal borides, carbides, nitrides, silicides, phosphides and sulfides; the latter such as boron carbide, Silicon carbide, boron nitride, silicon nitride, boron phosphide, silicon phosphide and the like. The latter has a very important use, can be used as high temperature refractory materials (such as abrasive, mold, nozzle, high temperature thermocouple casing), heat-resistant materials (such as rocket structure components, nuclear engineering materials, electric components), electrical materials Such as high temperature thermocouple, ignition electrode), in addition to chemical resistance materials and hard materials.

- Q: What insulating materials do you need for power tools?

- Reinforced insulation: the voltage between the live parts and the accessible housing is 3750V, such as the voltage between the brush and the cover surface; double insulation: basic insulation + additional insulation. Main insulating material: green paper or DMD Insulation paper for basic insulation; shaft insulation and plastic housing for additional insulation; rotor insulation end plate, stator insulation end plate, used to control the creepage distance and electrical clearance; brush grip bakelite powder, used to strengthen the insulation; other parts (Power plugs, commutators, switches, etc.) These are pressure requirements.

- Q: What insulating materials are used for high frequency transformers?

- In the production process of high-frequency transformers, insulation is a crucial step, this time you need to use a kind of insulation called the water, that is, paint. A class of artificial paint, shiny, good sticky. It is a paint that does not contain coloring matter. When applied to the substrate, it can form a transparent film with protection, decoration or special properties.

- Q: What is the insulating material in the middle of the connecting wire?

- With a transparent tape isolation, with hot melt adhesive fixed thread, with heat shrink tube insulation, a lot of ways ah.

- Q: What insulating material is best `?

- Liquid insulation material, also known as insulating oil. Fill the internal or inter-electrode gap between the solid material to improve its dielectric properties and improve the cooling capacity of the equipment. Liquid insulation material high breakdown strength, dielectric loss tangent (tgσ) small, insulation resistance High specific dielectric constant, in addition, also has excellent physical and chemical properties, such as high gasification temperature, high flash point, low freezing point, thermal conductivity, thermal stability, in the electric field under the suction Small and so on.

Send your message to us

Mica Parts Used for Induction Furnace for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches