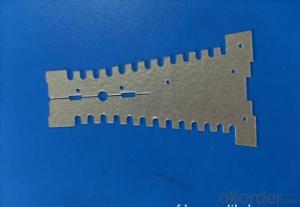

Mica Roll for High Temperature Indurstry Field

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications

High tensile strength;

Stable quality

Cost-efficient price.

Mica Paper is the continuous reeled paper made from high quality muscovite, phlogopite and synthetic mica with mechanical pulp methods.

The production process: reduce the mica scrap to powder, make paper, cut to the demand size and roll paper to finished products.

Outstanding Character:

1. Excellent insulating property.

2. High Tensile Strength.

3. Good resin penetration and air permeability.

4. Homogeneous distribution of granularity and structure.

5. Widely used in make Mica Plate, Mica Tape and etc.

Specification:

Width: 960-1050mm

Thickness: 0.04-0.15mm

| Type | Weight g/m2 | Thickness mm | Penetration time s(≤) | Dielectric strength KV/mm(≥) | Tensile strength N/cm(≥) | Loss due to heating at 500°C %(≤) | Conductivity of aqueous extract µs/cm(≤) | Temp. Resistant °C(≥) |

| 506 | 80 | 0.055 | 10 | 18 | 3 | 0.4 | 9 | 600 |

| 160 | 0.1 | 30 | 18 | 3.6 | 0.4 | 9 | 600 | |

| 250 | 0.15 | 60 | 18 | 5.5 | 0.4 | 9 | 600 | |

| 350 | 0.22 | 105 | 18 | 7 | 0.4 | 9 | 600 | |

| 507 | 60 | 0.04 | 10 | 18 | 3 | 0.4 | 9 | 600 |

| 160 | 0.1 | 40 | 18 | 4 | 0.4 | 9 | 600 | |

| 250 | 0.15 | 70 | 18 | 5 | 0.4 | 9 | 600 | |

| 350 | 0.22 | 130 | 18 | 7 | 0.4 | 9 | 600 | |

| P506 | 90 | 0.6 | 16 | 18 | 3 | 0.4 | 10 | 800 |

| 160 | 0.1 | 35 | 18 | 4 | 0.4 | 10 | 800 | |

| 250 | 0.15 | 70 | 18 | 5 | 0.4 | 10 | 800 | |

| 350 | 0.22 | 130 | 18 | 7 | 0.4 | 10 | 800 | |

| S506 | 105 | 0.065 | 10 | 19 | 3 | 0.25 | 6 | 1000 |

| 120 | 0.07 | 14 | 19 | 3 | 0.25 | 6 | 1000 | |

| 160 | 0.1 | 20 | 19 | 3.5 | 0.25 | 6 | 1000 | |

| 501 | 90 | 0.6 | 16 | 20 | 3 | 0.4 | 10 | 1000 |

| 160 | 0.1 | 35 | 20 | 4 | 0.4 | 10 | 1000 | |

| 250 | 0.15 | 70 | 20 | 5 | 0.4 | 10 | 1000 | |

| 350 | 0.22 | 130 | 20 | 7 | 0.4 | 10 | 1000 |

Packing: Wrapped up with PE film and fixed in wooden case.

- Q: What kind of insulation is the insulating

- Ordinary heat conduction is made with fiberglass PP2. High thermal conductivity materials are made of thermally conductive

- Q: What type of enameled wire and insulation material is used for the compressor

- Closed compressor, or semi-enclosed compressor, motor stator coil, and refrigerant, frozen oil have direct contact, refrigerant, frozen oil will not damage the insulation of the coil, enameled wire insulation material problems The Small to the refrigerator, freezer compressor, air conditioning compressor, large to semi-closed, fully enclosed chillers, are related to the coil insulation material. To tell the truth I only demolished medium-sized compressors (semi-enclosed compressors for cold storage). Large semi-enclosed high-pressure refrigeration compressor (6KV, 10KV) I only seen in the manufacturer, did not break

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Heat-resistant polymers can be used as high temperature resistant film insulation materials, high temperature resistant fibers, high temperature resistant coatings, high temperature adhesives. In accordance with the high temperature of the time, but also sub-instant high temperature materials and high temperature materials for a long time. The former in 1000 ~ 10000 ℃ can withstand a few seconds to a few minutes.

- Q: What insulating materials are used for high frequency transformers?

- Which is divided into solvent and solvent-free paint is divided into two major categories, mainly used for dipping motor, electrical coil and insulation parts to fill its gap and microporous, immersion paint can be cured in the surface of the formation of continuous formation Of the film, and the coil into a solid as a whole, in order to improve the insulation structure of the moisture, thermal conductivity, dielectric strength and mechanical strength of the performance.

- Q: What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q: What are the gas insulation materials?

- Gas insulation material refers to air, nitrogen, sulfur hexafluoride and other gases

- Q: What is the main purpose of insulating materials?

- The role of insulating material is in the electrical equipment to separate the potential of the live part of the insulation, so the insulation material should first have a high insulation resistance and pressure strength, and to avoid leakage, breakdown and other accidents.

- Q: Wear-resistant, high temperature, insulation materials which

- Epoxy, temperature from 100-400 degrees, processing more convenient. Ceramic is the best and cheap.

- Q: What are the electrical insulation materials

- Electrical insulation materials are wood, cotton, paper, oily paint, asphalt paint, polyester film, glass cloth, mica, glass fiber, asbestos, composite silicon organic polyester paint, quartz, glass, porcelain material.

- Q: What insulating material is best `?

- Liquid insulation material, also known as insulating oil. Fill the internal or inter-electrode gap between the solid material to improve its dielectric properties and improve the cooling capacity of the equipment. Liquid insulation material high breakdown strength, dielectric loss tangent (tgσ) small, insulation resistance High specific dielectric constant, in addition, also has excellent physical and chemical properties, such as high gasification temperature, high flash point, low freezing point, thermal conductivity, thermal stability, in the electric field under the suction Small and so on.

Send your message to us

Mica Roll for High Temperature Indurstry Field

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords