Aluminum Foil Facing Metalized PET/LDPE Laminated Polyester for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

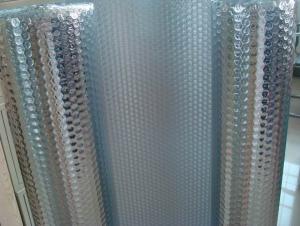

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil with a facing layer to wrap sandwiches?

- <p>Yes, aluminum foil facing can be used to wrap sandwiches. It provides a barrier to keep the sandwich fresh and protected. However, it's important to ensure that the facing layer is food-safe and doesn't contain any harmful substances that could leach into the food. Always check the packaging to confirm that the aluminum foil is suitable for food contact.</p>

- Q: Is it possible to use aluminum foil with a reflective surface for storing fruits and vegetables?

- <p>Aluminum foil facing can be used for storing fruits and vegetables, but it's not the best choice. Aluminum foil is not breathable and can cause condensation, leading to spoilage. It's better to use perforated or micro-perforated films that allow for air exchange while keeping light and moisture out. These films help maintain the freshness of produce by slowing down the respiration process and reducing water loss.</p>

- Q: This question is incomplete, but it seems to be asking about special cleaning methods required for a specific situation or item.

- <p>Special cleaning methods can vary greatly depending on the context. For instance, cleaning electronic devices requires anti-static wipes, while cleaning antiques may need gentle, non-abrasive cleaners. In the case of medical equipment, sterilization is crucial. For specific items like carpets, steam cleaning might be necessary. Always refer to manufacturer's instructions or professional guidelines for the best cleaning practices.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: Is it possible to recycle aluminum foil facing more than once?

- <p>Aluminum foil facing can be recycled, but it is typically not recycled multiple times due to the thinness and contamination issues. Recycling aluminum involves melting it down, and the thin foil can easily contaminate other aluminum products. Additionally, the foil facing is often laminated with other materials, making it difficult to separate and recycle. While some recycling facilities may accept it, the process is not as efficient as recycling other types of aluminum, and it's often advised to check with local recycling programs for their specific guidelines.</p>

- Q: This question asks for instructions on how to store food wrap materials after they have been used.

- <p>After using food wrap materials, it's important to clean them properly before storing. Rinse off any food residue with warm water and mild dish soap. Avoid using abrasive materials that could damage the wrap. Once clean, gently pat dry with a clean towel or let air dry. Store the wraps in a cool, dry place away from direct sunlight to prevent degradation. You can use a clean, airtight container or resealable plastic bag to keep them protected and dust-free. Always check for any signs of wear or damage before reusing to ensure food safety.</p>

- Q: Explain the differences between aluminum foil facing and other types of food wrap.

- <p>Aluminum foil facing is a type of food wrap that is made from thin sheets of aluminum, which provides excellent barrier properties against air, moisture, and light. It is often used for cooking, baking, and preserving food. Unlike plastic wraps, it does not stick to food and can withstand high temperatures without melting. Other types of food wraps, such as plastic or cling wraps, are made from polymers and are not heat resistant. They are typically used for short-term food storage and are not suitable for cooking. Paper-based wraps, like parchment or wax paper, are used for baking and providing a non-stick surface but do not offer the same barrier properties as aluminum foil.</p>

- Q: Can aluminum foil be shaped into a fish basket?

- <p>Yes, you can use aluminum foil facing to make a fish basket. Start by cutting a large piece of aluminum foil and folding it in half. Create a base by folding the edges up to form a shallow bowl shape. Then, fold the sides up and around, gradually narrowing the width to create the sides of the basket. Continue this process until you reach the desired height, ensuring the sides are sturdy enough to hold the fish. Seal the top with a final fold to complete the basket. This makeshift fish basket can be used for cooking or serving fish, but it's not recommended for heavy use or sharp objects due to the fragility of aluminum foil.</p>

- Q: The user wants to know if they can reuse their old aluminum foil facing to create a new one if it gets damaged.

- <p>Yes, you can use your old aluminum foil facing to make a new one if it gets damaged. Simply clean the old foil facing thoroughly, ensuring all adhesive residue is removed. Then, cut a new piece of aluminum foil to the appropriate size and shape. Apply a thin layer of adhesive, such as construction adhesive or double-sided tape, to the back of the new foil. Press it firmly onto the old facing, ensuring a smooth and secure bond. Allow it to dry according to the adhesive's instructions before using. This can be a cost-effective way to extend the life of your foil facing.</p>

- Q: This question asks for the optimal methods of storing food in containers not made of traditional food-safe materials.

- <p>The best ways to store food in containers made from alternative materials involve ensuring the containers are food-safe and do not impart any harmful substances to the food. For glass containers, ensure they are free of lead and are properly sealed to maintain freshness. For stainless steel containers, avoid those with non-food-grade coatings and ensure they are well-sealed to prevent spoilage. For silicone or plastic containers, look for BPA-free options and avoid high temperatures that could cause the material to leach chemicals. Always check for any odors or tastes that the container might impart to the food, and never store acidic foods in non-acid-resistant containers as this can lead to chemical reactions and contamination.</p>

Send your message to us

Aluminum Foil Facing Metalized PET/LDPE Laminated Polyester for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords