Aluminum Foil Facing Aluminum Foil Kraft Paper with LLDPE for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 inch

- Supply Capability:

- 30000 inch/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

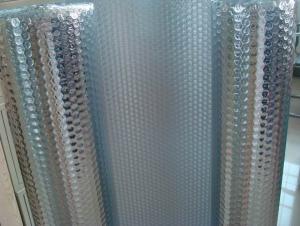

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: What are the options available to replace aluminum foil when covering food?

- <p>Yes, there are several alternatives to aluminum foil for covering food. Silicone food covers are reusable, heat-resistant, and can be easily washed. Beeswax wraps are an eco-friendly option, made from natural materials and can be used multiple times. Parchment paper is a disposable option that's ideal for baking and can be used in place of foil. Reusable glass or ceramic lids can be used for dishes that need to be covered while cooking. Lastly, some people opt for reusable metal mesh covers, which are suitable for grilling and baking. Each alternative has its own benefits and is chosen based on the specific needs and preferences of the user.</p>

- Q: Describe the optimal method for utilizing aluminum foil facing in cooking.

- <p>The best way to use aluminum foil facing for cooking is to preheat your oven and ensure the foil is shiny side up to reflect heat. For baking, create a tent with the foil to protect delicate foods from direct heat, which can prevent burning. When roasting, use foil to wrap foods like fish or vegetables to steam them, enhancing flavor and moisture retention. For grilling, use foil to create packets to cook foods indirectly or to line the grill to prevent food from sticking. Always handle with care to avoid tearing and ensure even heat distribution.</p>

- Q: What are the various levels or types of aluminum foil facing materials used in construction or insulation?

- <p>Aluminum foil facing is used in various applications such as insulation and construction. The different grades include: 1) Plain Aluminum Foil Facing, which is a basic type without any additional features. 2) Reinforced Aluminum Foil Facing, which is stronger and more durable, often used for heavy-duty applications. 3) Coated Aluminum Foil Facing, which has a protective coating for enhanced performance. 4) Laminated Aluminum Foil Facing, which combines aluminum with other materials for specific properties. Each grade offers unique benefits depending on the application's requirements.</p>

- Q: Is it safe to reuse aluminum foil for food packaging purposes?

- <p>While it may be tempting to reuse aluminum foil for food packaging, it is generally not recommended due to hygiene and safety concerns. Recycled aluminum foil can harbor bacteria and other contaminants, which can be transferred to the food. Additionally, the foil can tear easily when reused, leading to potential food waste. It's best to use fresh aluminum foil each time to ensure food safety and maintain the integrity of your packaging.</p>

- Q: Describe the optimal method for utilizing aluminum foil facing in culinary applications.

- <p>The best way to use aluminum foil facing in cooking is to preheat the oven to the desired temperature, then line the baking sheet or roasting pan with a sheet of aluminum foil, shiny side up. This helps prevent food from sticking and makes cleanup easier. When roasting meats or vegetables, you can also wrap them in foil to retain moisture and speed up cooking. Ensure the foil is not touching the heating elements to avoid fire hazards. For grilling, use foil to wrap foods like corn on the cob or to create a makeshift baking sheet for delicate items. Always be cautious with acidic foods as they can react with the aluminum.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foils, highlighting their differences.

- <p>Aluminum foil facing is distinct from other metal foils due to its specific properties. It is lightweight, highly reflective, and offers excellent heat conductivity, making it ideal for insulation and cooking applications. Unlike other metal foils, aluminum foil is non-toxic and can be safely used in food packaging and preparation. It is also corrosion-resistant and has a lower melting point compared to metals like steel or copper, which affects its usability in various industries. Additionally, aluminum foil is more affordable and widely available than some other metal foils, contributing to its popularity in everyday use.</p>

- Q: This question asks for methods to store aluminum foil to prevent damage and rusting.

- <p>Aluminum foil is resistant to rusting, but it can still be damaged if not stored properly. To store aluminum foil, keep it in a cool, dry place away from direct sunlight. Use an airtight container or a resealable plastic bag to protect it from moisture and air, which can cause it to oxidize and lose its shine. Avoid stacking heavy items on top of it, as this can cause dents and tears. If you have a large amount, consider using a foil storage box with compartments to keep it organized and protected.</p>

- Q: Explain the various applications of aluminum foil facing in different contexts.

- <p>Aluminum foil facing can be used in various ways depending on the application. In construction, it serves as a vapor barrier to prevent moisture from affecting the insulation. In packaging, it's used for food preservation, providing a barrier against air and light, which helps to keep food fresh. In the automotive industry, it's used for heat reflection and insulation in car engines. It's also used in the manufacturing of reflective materials and in art for creating unique textures and effects. Additionally, aluminum foil facing is utilized in the aerospace industry for heat shielding and in the medical field for sterilization purposes. Each application leverages the properties of aluminum foil, such as its light weight, durability, and heat resistance.</p>

- Q: The user wants to know if they can reuse their old aluminum foil facing to create a new one if it gets damaged.

- <p>Yes, you can use your old aluminum foil facing to make a new one if it gets damaged. Simply clean the old foil facing thoroughly, ensuring all adhesive residue is removed. Then, cut a new piece of aluminum foil to the appropriate size and shape. Apply a thin layer of adhesive, such as construction adhesive or double-sided tape, to the back of the new foil. Press it firmly onto the old facing, ensuring a smooth and secure bond. Allow it to dry according to the adhesive's instructions before using. This can be a cost-effective way to extend the life of your foil facing.</p>

- Q: Is it possible to use aluminum foil facing in the process of making desserts or cakes?

- <p>Yes, you can use aluminum foil facing to make desserts or cakes. It is commonly used for lining baking pans to prevent sticking and to ensure easy removal of the baked goods. Aluminum foil is heat resistant and can be used in the oven, but it's important to avoid direct contact with the heating elements to prevent burning. For best results, use heavy-duty aluminum foil and ensure it covers the bottom and sides of the pan completely.</p>

Send your message to us

Aluminum Foil Facing Aluminum Foil Kraft Paper with LLDPE for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 inch

- Supply Capability:

- 30000 inch/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords