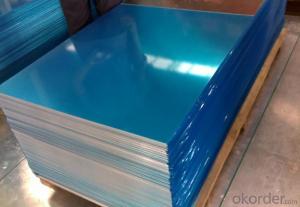

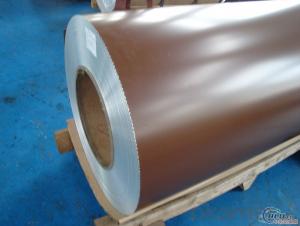

Menards Aluminum Coil Stock PVDF Coated Aluminum Sheet for Solar Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVDF Coated Aluminium Roll For Solar Panels

Specifications

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-8.0 mm aluminium 7075 t6 |

Width | 1250mm 1000mm 1219mm or as your requirements |

MOQ | 8 Ton |

Package | Standard export package, by wooden box or as required. |

Application | 1060 is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other. |

Characteristics

1) Excellent weather-proof durability

2) Anti-ultraviolet

3) High erosion resistance

4) Stable color and gloss

5) Good mechanical processing performance

6) Abrasion resistance

7) Anti-impact

8) High flexibility

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

- Q: why is aluminum oxide used more frequently than silicon carbide as an abrasive?What r the different types of tool feed mechanism in USM process.

- It may well be cheaper. Making silicon carbide is fairly energy intensive.

- Q: This question asks for the method to cut an aluminum coil into smaller sections.

- <p>To cut an aluminum coil into smaller pieces, you can use a metal cutting band saw, which is designed for cutting metal materials. Ensure the blade is sharp and the speed is appropriate for aluminum. Secure the coil in a vice or a cutting table to prevent movement during cutting. Wear safety goggles and gloves. Turn on the saw and slowly feed the coil through the blade, applying steady pressure. After cutting, smooth any rough edges with a file or sandpaper. Always follow safety precautions and manufacturer's instructions for your specific cutting tool.</p>

- Q: What are the advantages of using aluminum coils in various industries?

- Using aluminum coils in various industries offers several advantages. Firstly, aluminum is lightweight, making it easy to handle and transport. This is especially beneficial in industries like aerospace and automotive, where reducing weight improves fuel efficiency and overall performance. Secondly, aluminum has excellent corrosion resistance. It forms a natural oxide layer that protects it from rust and other forms of corrosion, making it durable and long-lasting. This makes aluminum coils suitable for industries like construction, marine, and HVAC, where exposure to moisture and harsh environments is common. In addition, aluminum has high thermal conductivity, efficiently transferring heat. This makes it ideal for heat exchangers, refrigeration systems, and other applications requiring effective heat dissipation. Moreover, aluminum is highly recyclable, requiring less energy than producing primary aluminum. Using aluminum coils promotes sustainability and reduces environmental impact, making it attractive for companies aiming to adopt eco-friendly practices. Furthermore, aluminum coils can be easily formed and shaped into various sizes and dimensions, allowing for flexible design options and customization. This versatility makes it suitable for a wide range of applications in industries like packaging, electrical, and telecommunications. Lastly, aluminum coils offer cost advantages in terms of initial investment and maintenance. While the upfront cost may be higher than other materials, the long-term benefits of durability, low maintenance requirements, and energy efficiency make it a cost-effective choice. In conclusion, the advantages of using aluminum coils in various industries include lightweight nature, corrosion resistance, high thermal conductivity, recyclability, versatility, and cost-effectiveness. These qualities make aluminum coils a preferred material for many industrial applications, contributing to improved performance, durability, and sustainability.

- Q: What is the typical coil width for aluminum coils?

- The typical coil width for aluminum coils can vary depending on the specific application and industry. However, in general, the coil width for aluminum coils can range from a few inches to several feet. Common coil widths for aluminum coils used in construction, automotive, and packaging industries typically range from 12 inches to 72 inches. These coil widths are often selected based on the requirements of the manufacturing process, the final product dimensions, and the equipment used for coil processing. It is important to note that specific coil widths may be customized based on the customer's needs and production capabilities of the aluminum coil manufacturer.

- Q: This question asks about the impact of aluminum coils on cooking equipment, including their role in heat distribution and potential benefits or drawbacks.

- <p>Aluminum coils in cooking equipment play a significant role in heat distribution and retention. They are known for their excellent thermal conductivity, which allows for even heat distribution across the cooking surface, reducing hot spots and ensuring consistent cooking results. Aluminum's lightweight and malleability also make it easy to shape into various forms, fitting different types of cookware. However, aluminum can react with acidic foods, potentially altering the taste or releasing small amounts of aluminum into the food, which some studies suggest could have health implications. Additionally, aluminum cookware requires careful handling to avoid scratches that can compromise its performance and appearance.</p>

- Q: I'm 14 an was told that aluminum free deodorant would stop yellow stains on my white shirts, so which female deodorant would help stop yellow stains

- Deodorant with aluminum also causes breast cancer. I use Toms of Maine deodorant, which is aluminum-free.

- Q: What are the potential health hazards associated with the use of old aluminum coils?

- <p>Using old aluminum coils can pose health risks due to potential leaching of aluminum into food or beverages. Long-term exposure to aluminum may lead to cognitive impairments and neurological issues. Additionally, old coils may have accumulated dirt, bacteria, or other contaminants that could cause infections or digestive problems. It's important to regularly inspect and replace aluminum cookware to ensure safety.</p>

- Q: I want to roll aluminum rolls and operate the machine for more than three years

- (2) shutdown leaves firewood period (during inductrial injury treatment and rehabilitation) according to the original wage compensation;

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- when this phenomenon occurs in feeding occurs when you say the phenomenon, when parking tension shock or mutation, the inner drum contraction material, inner sleeve trace diameter decreases, emergency stop when the inertia torque increase, will influence on the oil film, and is the inner bag sleeve is not tight, causing the inner diameter decreases due to aluminum transfer from the inner ring to slide staggered, outer ring, the outer ring can be transferred to the volume of the material into a neat is not neat, not fully delivered appeared loose layer.

- Q: How do aluminum coils contribute to reduced carbon emissions?

- There are several ways in which aluminum coils help reduce carbon emissions. To begin with, aluminum is a lightweight material, unlike other metals such as steel. This means that less energy is needed to transport and handle aluminum coils. The reduced weight leads to lower fuel consumption during transportation, ultimately resulting in decreased carbon emissions. Moreover, the production of aluminum coils requires significantly less energy compared to other metals. Aluminum is highly recyclable and can be melted down and reused without losing its original properties. This recycling process only requires a fraction of the energy needed to produce aluminum from raw materials, resulting in reduced greenhouse gas emissions. In addition, aluminum coils have excellent thermal conductivity. This allows for improved energy efficiency in various applications. For instance, aluminum coils are commonly used in HVAC systems, where they help transfer heat more effectively. This reduces the energy required for heating or cooling, ultimately leading to lower carbon emissions. In summary, the lightweight nature of aluminum coils, their recyclability, and their improved energy efficiency all contribute to reduced carbon emissions. By utilizing aluminum coils in different industries, we can minimize environmental impact, conserve energy resources, and mitigate climate change.

Send your message to us

Menards Aluminum Coil Stock PVDF Coated Aluminum Sheet for Solar Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords