Flat Rolled Aluminum Coil Toronto - DC Process Aluminum Coil for Casting to Thinner Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DC Process Aluminum Coil for Casting to Thinner Coils

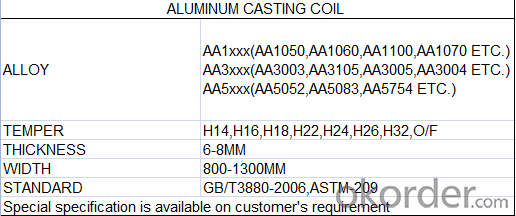

1.Structure of DC Process Aluminum Coil for Casting to Thinner Coils

DC Process Aluminum Coil for Casting to Thinner Coils is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. The thickness of DC Process Aluminum Coil for Casting to Thinner Coils is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the DC Process Aluminum Coil for Casting to Thinner Coils

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. DC Process Aluminum Coil for Casting to Thinner Coils

4. Production Process of DC Process Aluminum Coil for Casting to Thinner Coils

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of DC Process Aluminum Coil for Casting to Thinner Coils

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: Explain the distinctions among various welding equipment used specifically for joining aluminum coils.

- <p>Different types of welding equipment for aluminum coils include Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Resistance Welding (RW). GTAW, also known as TIG welding, uses a non-consumable tungsten electrode and produces high-quality welds with minimal distortion. GMAW, or MIG welding, uses a continuous wire feed as the electrode and is faster but may not be as precise. Resistance Welding involves using electrical current to heat the metals at the joint, which is quick and efficient but not suitable for all aluminum alloys. Each method has its advantages and is chosen based on factors like weld quality, speed, and the specific aluminum alloy being welded.</p>

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q: is there any kind of solder or technique that can solder copper to aluminium? or is it just not possible!?

- Conventional tin/lead alloys cannot be used to solder aluminium to anything: it's just not possible.

- Q: What are the factors that affect the cost of aluminum coils?

- There are several factors that can affect the cost of aluminum coils, including the current market demand and supply, the quality and grade of the aluminum used, the size and thickness of the coils, transportation and logistics costs, currency exchange rates, and any applicable taxes or tariffs.

- Q: What are the weight ranges of aluminum coils?

- The size and thickness of aluminum coils determine their weight ranges, which can vary greatly. Aluminum coils can weigh anywhere from a few hundred pounds to several thousand pounds. Coils used for household purposes or in manufacturing small parts usually weigh around 100-500 pounds. Coils commonly used in construction or automotive industries range from 500-2,000 pounds. On the other hand, larger coils utilized in heavy-duty applications like aerospace or marine industries can exceed 2,000 pounds and sometimes even surpass 10,000 pounds. It is important to emphasize that these weight ranges are approximate and can differ based on the specific requirements of a particular project or application.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: Are aluminum coils resistant to chemicals?

- Generally, chemicals do not pose a problem for aluminum coils due to their inherent resistance. This is because aluminum naturally develops a protective oxide layer on its surface, which shields it from various chemicals. Consequently, the oxide layer effectively prevents corrosion and deterioration of the aluminum coils when they come into contact with different substances. Nevertheless, it is worth mentioning that certain chemicals, particularly potent acids or alkalis, can still harm aluminum. In such instances, applying additional protective coatings or treatments becomes essential to strengthen the chemical resistance of the aluminum coils.

- Q: Can aluminum coils be used in the manufacturing of cans and containers?

- Cans and containers can indeed be manufactured using aluminum coils. Aluminum, being a lightweight and durable material, is extensively utilized in the packaging sector. The usual procedure involves rolling aluminum coils into thin sheets, which are subsequently cut and molded into the desired shape for cans and containers. These coils present an economical and efficient means of producing large quantities of cans and containers, as they can be effortlessly processed and molded. Moreover, aluminum is a remarkably recyclable material, contributing to its eco-friendly and sustainable nature within the packaging industry. All in all, due to their versatility, durability, and recyclability, aluminum coils are widely employed in the manufacturing of cans and containers.

- Q: How do aluminum coils compare to copper coils?

- Aluminum coils are generally lighter and less expensive than copper coils, but they have lower thermal conductivity and may require larger coil sizes. Copper coils, on the other hand, have superior heat transfer properties, making them more efficient for cooling or heating applications.

Send your message to us

Flat Rolled Aluminum Coil Toronto - DC Process Aluminum Coil for Casting to Thinner Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords