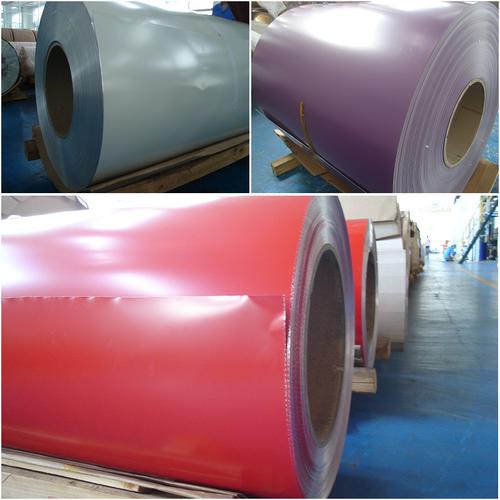

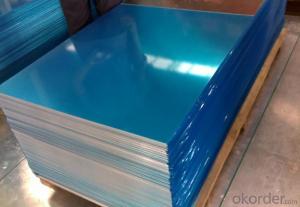

PVDF Coated Aluminum Sheet Coil Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of PVDF AluminumCoil:

1. Adopting precision rolling coating technology,our PE coated coil can ensure excellent adhesive without coating omission.

2. For the PVDF coated aluminum sheet we produced,there are various colors for your choice.

3. Using infrared heating technology to protectenvironment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

Raw Material of the PVDF Coated Aluminum Coil:

1. Aluminum Coil: high strength aluminum with alloyof AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005 according tocustomer)

2. Surface Paint: PE, PVDF and special paints.

Specification of the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

Performance and usage

PVDF coated aluminum coils are specially processedthrough the technics of roller coating and baking with precise paints fromBECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

Color of Card

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, soit is suggested all panels are placed in one order for same project. And keepsame direction as arrow on protective film when installing to avoid any colordifference by vision.

- Q: also, can aluminum become oxidized when secured down with metal nuts and bolts vice stainless steel nuts and bolts?

- Aluminum is very reactive to caustic substances, as well as acids. One of the perils of running nitrous oxide injection on a motor with aluminum heads or pistons is that you generate trace amounts of nitric acid which will corrode these parts over time. As mentioned here by other members, aluminum oxide is a powdery white residue. In the presence of water for a long period of time, or with the reactions mentioned above, aluminum will oxidize. If it's wheels you are talking about, the best solution is to keep them clean, dry, and free of brake dust. A lot of wheels though come with a coating to protect the aluminum.

- Q: I need help with 3 main ideas for a aluminum and copper chloride lab. I need evidence for these 3 ideas that what happened was a chemical reaction.

- Aluminum metal usually has a passivating layer of Al2O3 which prevents aluminum from reacting with Cu2+ ions. Al won't react with CuSO4(aq), for instance. But if NaCl is added then it will. It is the effect of the chloride ion that makes the reaction go. Al2O3(s) + 8Cl-(aq) + 3H2O -- 2[AlCl4]^- + 6OH- Once the passivating layer is dissolved, then aluminum metal is available to react with chloride ion. You see the aluminum metal disappear, while dark red Cu metal is formed, along with the decrease in the blue color due to hydrated copper ions, [Cu(H2O)6]^2+. In addition, aluminum metal has a side-reaction with water to form hydrogen gas. Therefore, you will observe that as gas is given off. Not only that, the temperature of the solution will increase. 2Al(s) + 2OH- + 6H2O -- 2[Al(OH)4]- + 3H2(g) In summary. There are four indicators of a chemical reaction. 1. The formation of a precipitate 2. The evolution of a gas 3. A color change 4. A temperature change. All four indicators are observed. Solid Cu metal is formed. Hydrogen gas is given off. The color of the solution changes from blue to colorless, and the temperature increases.

- Q: How do aluminum coils contribute to sustainable transportation?

- Aluminum coils play a crucial role in promoting sustainable transportation in several ways. Firstly, aluminum is a lightweight material, making it an ideal choice for various components in vehicles. By replacing heavier materials such as steel, aluminum coils help to reduce the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces greenhouse gas emissions. Furthermore, the use of aluminum coils in vehicle manufacturing helps to enhance the durability and longevity of the vehicle. Aluminum is highly resistant to corrosion, which is particularly beneficial in areas with harsh weather conditions or high levels of road salt. This longevity means that vehicles made with aluminum coils require less frequent repairs and replacements, reducing the amount of waste and resources consumed over the lifetime of the vehicle. In addition, the recyclability of aluminum is another significant factor in sustainable transportation. Aluminum is one of the most recyclable materials on the planet, with almost 75% of all aluminum ever produced still in use today. By using aluminum coils, manufacturers can incorporate recycled aluminum into their production processes, reducing the need for primary aluminum extraction. This not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions associated with aluminum production. Moreover, aluminum coils contribute to sustainable transportation by enabling the advancement of electric vehicles (EVs). The lightweight nature of aluminum helps to improve the range and efficiency of EVs by reducing their energy consumption. Additionally, aluminum's excellent thermal conductivity allows for better heat dissipation in EV batteries, enhancing their performance and lifespan. Overall, the use of aluminum coils in transportation supports sustainability efforts by reducing vehicle weight, improving fuel efficiency, increasing durability, promoting recycling, and enabling the growth of electric vehicles. As the transportation sector continues to strive for reduced emissions and increased efficiency, aluminum coils will continue to play a vital role in achieving these sustainability goals.

- Q: How are aluminum coils used in heating, ventilation, and air conditioning (HVAC) systems?

- Aluminum coils hold a vital role in HVAC systems, specifically in heating, ventilation, and air conditioning. These coils are implemented in both the condenser and evaporator parts of the system. In the condenser, the aluminum coils aid in the transfer of heat from the refrigerant to the surrounding air. The refrigerant, which is in a state of high pressure and temperature after compression, flows through the condenser coils. As the air from the surroundings passes over these coils, the heat from the refrigerant moves to the air. This procedure contributes to the cooling of the refrigerant, transforming it from a gas into a liquid state. The cooled liquid refrigerant then moves to the evaporator coil. In the evaporator, the aluminum coils help in the absorption of heat from the indoor air. The liquid refrigerant enters the evaporator coils, where it experiences a change in phase from liquid to gas. As the warm indoor air passes over the coils, the refrigerant absorbs the heat, resulting in the cooling of the air. This cooled air is subsequently circulated back into the room, creating a comfortable indoor environment. The preference for aluminum coils in HVAC systems stems from their outstanding thermal conductivity, resistance to corrosion, and lightweight properties. These characteristics ensure effective heat transfer and enhance the overall performance of the system. Moreover, aluminum coils are more cost-efficient and environmentally friendly compared to materials like copper. Regular maintenance and cleaning of the aluminum coils are imperative to maintain their optimal functioning. Over time, dirt, dust, and debris can accumulate on the surface of the coils, hindering heat transfer and reducing efficiency. Thus, periodic cleaning is essential to preserve the performance of the HVAC system and prolong the lifespan of the aluminum coils.

- Q: Can aluminum coils be used for nameplates and labels?

- Indeed, nameplates and labels can utilize aluminum coils. Aluminum, being a versatile material, presents numerous benefits in this regard. Notably, its lightweight nature coupled with its durability renders it suitable for diverse applications. Furthermore, aluminum boasts exceptional resistance to corrosion, making it an excellent choice for outdoor usage or environments with high humidity levels. Moreover, aluminum lends itself easily to stamping, embossing, or engraving, thereby facilitating the creation of intricate designs and detailed text. Additionally, it is feasible to apply coatings or anodize aluminum coils to augment their visual appeal or provide added protection. All in all, aluminum coils offer a dependable and cost-efficient solution for nameplates and labels.

- Q: ok me and my father are trying to make thermite. we have the iron oxide but the aluminum we only have paste and i was wondering would it work the same as if we had the powder.and if it is differnt will it work for the thermite and what will it take to light it.

- You okorder /

- Q: How do aluminum coils compare to other materials in terms of strength?

- Aluminum coils are known for their remarkable strength-to-weight ratio, making them highly competitive compared to other materials. While aluminum may not be as strong as certain metals like steel or titanium, it still possesses sufficient strength to meet the demands of various applications. The specific strength of aluminum coils refers to their strength relative to their weight, which is often superior to other materials. Additionally, aluminum coils offer exceptional corrosion resistance, which further enhances their durability and longevity. Although there may be stronger materials available, aluminum coils remain an excellent choice for many industries due to their favorable strength characteristics and numerous other benefits.

- Q: What are the common problems faced with aluminum coils?

- Some common problems faced with aluminum coils include corrosion, poor heat transfer, refrigerant leaks, and coil damage due to mechanical stress or improper maintenance.

- Q: Is it possible to utilize aluminum coils in the production of baking pans or trays?

- <p>Yes, aluminum coils are commonly used for making baking pans and trays due to their excellent heat conductivity, lightweight, and durability. Aluminum's non-reactive nature also makes it safe for food contact. However, it's crucial to ensure that the aluminum is food-grade and that the manufacturing process adheres to safety standards to prevent any health risks.</p>

- Q: What are the different types of edge conditions for aluminum coils?

- There are several types of edge conditions for aluminum coils, including slit edge, mill edge, deburred edge, round edge, and beveled edge. Each type has specific characteristics and is used for different applications in industries such as construction, automotive, and aerospace.

Send your message to us

PVDF Coated Aluminum Sheet Coil Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords