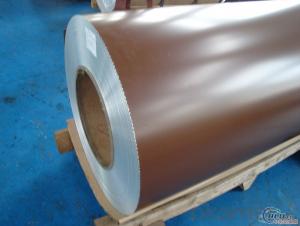

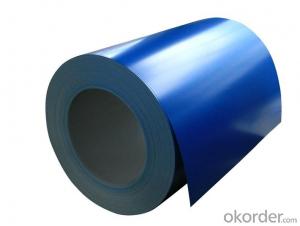

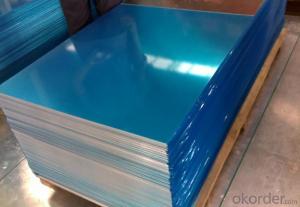

1050 Aluminum Coils PVDF Color Coated Aluminum Sheet for Automobile Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVDF Color Coated Aluminium Sheet For Automobile Parts

Specifications

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-8.0 mm aluminium 7075 t6 |

Width | 1250mm 1000mm 1219mm or as your requirements |

MOQ | 8 Ton |

Package | Standard export package, by wooden box or as required. |

Application | 1060 is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other. |

Characteristics

1) Excellent weather-proof durability

2) Anti-ultraviolet

3) High erosion resistance

4) Stable color and gloss

5) Good mechanical processing performance

6) Abrasion resistance

7) Anti-impact

8) High flexibility

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

- Q: How do aluminum coils perform in extreme temperature conditions?

- Aluminum coils exhibit satisfactory performance in extreme temperature conditions. With a high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), aluminum is well-suited for handling high temperatures. Additionally, its exceptional thermal conductivity allows for efficient heat transfer and rapid cooling in extreme heat situations. This characteristic proves particularly advantageous in applications like air conditioning systems and refrigeration units, where aluminum coils are commonly utilized. Furthermore, aluminum is renowned for its corrosion resistance, a quality that is vital in extreme temperature settings. It resists oxidation and does not easily succumb to rust, ensuring the durability and longevity of the coils. This resistance to corrosion is especially significant in environments characterized by high humidity or exposure to salt, where alternative metals may rapidly corrode. Nevertheless, it is important to note that the performance of aluminum coils may be affected by extremely cold temperatures. In such conditions, aluminum contracts and becomes more brittle, potentially leading to reduced flexibility and even cracking. Consequently, it becomes crucial to provide proper insulation and protection to prevent any damage to the coils in extremely cold surroundings. Overall, aluminum coils can be relied upon and demonstrate commendable performance in extreme temperature conditions, particularly in applications involving high temperatures. Their high melting point, excellent thermal conductivity, and resistance to corrosion render them suitable for a wide range of industries and environments.

- Q: What are the common installation methods for aluminum coils?

- There are several common installation methods for aluminum coils. 1. Direct Attachment: This method involves directly attaching the aluminum coils to the desired surface, such as a wall or roof. This can be done using screws, nails, or adhesive, depending on the specific application and the condition of the surface. Direct attachment is a popular method for installing aluminum coils in exterior applications like siding and roofing. 2. Coil Stock Installation: In this method, the aluminum coil is cut into smaller pieces called coil stock and then installed individually. This is often used for projects that require a more customized fit, such as wrapping window frames or creating trim pieces. Coil stock installation requires careful measurement and cutting to ensure a precise fit. 3. Coil Over Existing Material: In some cases, aluminum coils can be installed directly over existing materials, such as old siding or roofing. This method is often used as a cost-effective solution to update the appearance of a building without completely removing and replacing the existing material. It can save time and labor costs compared to other installation methods. 4. Coil Cladding: Another common installation method for aluminum coils is coil cladding. This involves wrapping the aluminum coil around an existing structure, such as a column or beam, to provide a protective and decorative covering. Coil cladding is often used in architectural applications to enhance the appearance of buildings and add a layer of protection to structural elements. It's important to note that the specific installation method for aluminum coils can vary depending on the application, the condition of the surface, and the desired outcome. It is recommended to consult with a professional or follow manufacturer guidelines to ensure proper installation and maximize the longevity and performance of the aluminum coils.

- Q: I am shopping for new Rollerblades and see their newer skates have Aluminum framesand not the composite which I feel is more sturdier. What do you think of the aluminumframes? I was not impressed.

- complicated matter. research on google. this can assist!

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- racing okorder /... they have part specifically designed for improving performance on your Mustang. mixing a variaty of parts from defferent manufactures does not always increase performance. cams, heads, lifter, rockers, fuel system components need to be match for the type of performance increase you are looking for and at fordracing these parts are matched into different performance improvement types. Check out the web site it will get you started in the right direction for what you are looking for.

- Q: Why does the heat preservation aluminum roll bend when it is cooled?

- In recent years, because the iron sheet in the heat preservation industry does not have rust prevention effect, so now in the domestic aluminum sheet has fully replace iron sheet.

- Q: Are there any restrictions on the coil length of aluminum coils?

- Restrictions do exist regarding the length of aluminum coils. Typically, the maximum coil length is determined by the capabilities of the equipment utilized for coil production and handling. Several factors contribute to this determination, including the dimensions and capacity of coil winding machines, transportation and storage restrictions, and the coil's weight and stability. Moreover, longer coils may encounter increased handling and logistical challenges, such as heightened risk of damage during transportation or difficulties in uncoiling and processing. Consequently, it is crucial to take into account these restrictions and limitations when deciding on the suitable length for aluminum coils.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum coils are preferred for HVAC ductwork due to their lightweight and corrosion-resistant properties. They are highly durable and can withstand extreme temperatures and weather conditions. Additionally, aluminum coils have excellent thermal conductivity, which allows for efficient heat transfer and ensures optimal cooling or heating performance. Moreover, aluminum is a non-toxic material, making it safe for use in HVAC systems. Overall, aluminum coils are an ideal choice for HVAC ductwork, providing long-lasting performance and energy efficiency.

- Q: Can aluminum coils be used in the production of aluminum composite roofs?

- Aluminum composite roofs can indeed utilize aluminum coils. Due to their durability, lightweight composition, and corrosion resistance, aluminum coils are frequently employed in the manufacturing process of aluminum composite roofs. These coils can be effortlessly molded and arranged into the desired roof profile, resulting in a smooth and visually pleasing final product. Furthermore, aluminum possesses exceptional thermal and sound insulation qualities, rendering it an optimal selection for roofing purposes. Its remarkable strength-to-weight ratio additionally bolsters the overall structural stability of the roof. In summary, the utilization of aluminum coils in the production of aluminum composite roofs furnishes a dependable and enduring roofing solution.

- Q: What are the density and specific gravity values of aluminum coils?

- The density of aluminum coils is approximately 2.7 g/cm³, and the specific gravity value is approximately 2.7.

- Q: Inquiry about the feasibility of using aluminum coils for crafting jewelry or accessories.

- <p>Yes, you can use aluminum coils to make jewelry or accessories. Aluminum is lightweight, durable, and non-allergenic, making it a popular choice for crafting. It's easy to shape and work with, and it's also cost-effective compared to precious metals. You can create rings, bracelets, necklaces, and various other decorative items. Just ensure you use the right tools and safety precautions when working with metal, and finish your creations with appropriate polishing and sealing to enhance their appearance and longevity.</p>

Send your message to us

1050 Aluminum Coils PVDF Color Coated Aluminum Sheet for Automobile Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords