Membran Weldable and Valcanization for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14000 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Membran Weldable and Valcanization for Waterproof System

Description Of Membrane Weldable:

1. EPDM membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Membran Weldable and Valcanization for Waterproof System

1. High puncture resistance

2. High aging resistance

3. UV resistance

Membran Weldable and Valcanization for Waterproof System

Material | Ternary Ethylene-Propylene rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Applications of Membran Weldable and Valcanization for Waterproof System

1. Industrial and civil building waterproofing

2. Geosynthetic liner for swimming pool, channels, irrigation system

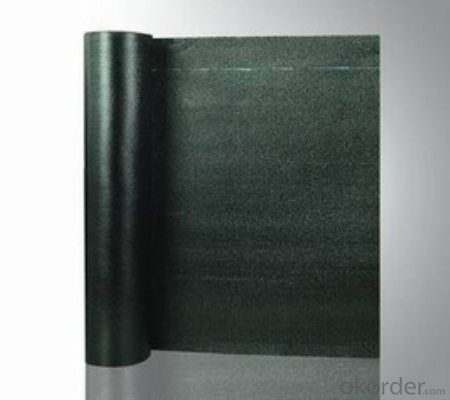

IMages of Membran Weldable and Valcanization for Waterproof System

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 4 hours.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Yes, a waterproofing membrane can be used on precast insulation surfaces. A waterproofing membrane is designed to provide a protective barrier against water infiltration, and it can be applied to a variety of surfaces, including precast insulation. The membrane helps to prevent water from seeping into the insulation, which can cause damage and reduce its effectiveness. By applying a waterproofing membrane to precast insulation surfaces, you can ensure that the insulation remains dry and maintains its thermal properties over time.

- Q: Can a waterproofing membrane be used for train platforms?

- Train platforms can indeed benefit from the application of a waterproofing membrane. Given their exposure to different weather conditions like rain and snow, it is important to address potential water damage and deterioration over time. One effective method is to install a waterproofing membrane on the surface of the platform. This protective barrier prevents water from seeping through and causing harm to the underlying structure. Consequently, this approach not only prolongs the platform's lifespan but also reduces maintenance costs and ensures the safety of passengers and personnel. In addition, the use of a waterproofing membrane can help prevent the growth of mold and mildew, which can negatively impact the health of those using the train platform. All in all, utilizing a waterproofing membrane on train platforms proves to be a practical and efficient solution for safeguarding against water damage and maintaining the infrastructure's longevity.

- Q: Can waterproofing membranes be used on utility manholes?

- Yes, waterproofing membranes can be used on utility manholes. Waterproofing membranes are specifically designed to provide a barrier against water infiltration, making them suitable for use in areas where water is present, such as manholes. These membranes are typically applied to the walls and floors of the manhole to prevent water from seeping through and causing damage to the structure or the utilities within. By effectively sealing off the manhole, waterproofing membranes help to maintain the integrity and functionality of the utilities and prevent water-related issues such as corrosion, leaks, and the degradation of materials. Additionally, waterproofing membranes can also provide protection against other elements such as chemicals, gases, and soil contaminants that may be present in or around the manhole. Therefore, using waterproofing membranes on utility manholes is a common practice to ensure their long-term durability and functionality.

- Q: How are waterproofing membranes installed?

- Waterproofing membranes are installed to protect buildings and structures from water damage. The installation process typically involves several steps. First, the surface that is to be waterproofed must be properly prepared. This usually involves cleaning the surface and removing any debris or loose materials. It is important to ensure that the surface is smooth and free of any irregularities or cracks. Next, a primer is applied to the surface. This helps to create a strong bond between the membrane and the surface. The primer is typically applied using a brush or roller, and it is allowed to dry completely before moving on to the next step. Once the surface is primed, the waterproofing membrane can be installed. There are several different types of membranes available, including sheet membranes, liquid membranes, and peel-and-stick membranes. The specific type of membrane used will depend on the needs of the project and the surface being waterproofed. For sheet membranes, the material is typically unrolled and carefully positioned over the primed surface. It is important to ensure that the membrane is properly aligned and that there are no wrinkles or air pockets. The membrane is then pressed down firmly to create a strong bond with the surface. Liquid membranes are typically applied using a brush or roller. The liquid is spread evenly over the primed surface, and multiple coats may be applied to ensure a complete and effective waterproofing layer. It is important to allow each coat to dry before applying the next. Peel-and-stick membranes are the easiest to install. The backing is peeled off the membrane, and it is carefully pressed onto the primed surface. The adhesive on the back of the membrane creates a strong bond with the surface. Once the membrane is installed, any seams or joints must be properly sealed. This is typically done using a waterproofing tape or sealant. The goal is to create a continuous and watertight barrier to prevent any water from seeping through. Overall, the installation process for waterproofing membranes requires careful preparation, proper application, and attention to detail. It is important to follow the manufacturer's instructions and to use the appropriate materials and techniques for the specific membrane being installed. By doing so, a reliable and effective waterproofing system can be created to protect the building or structure from water damage.

- Q: Can a waterproofing membrane be used for underwater structures?

- Indeed, underwater structures can benefit from the utilization of a waterproofing membrane. These membranes have been specifically engineered to create a formidable barrier against water infiltration, rendering them appropriate for various applications, including underwater structures. Typically composed of robust materials like reinforced PVC or rubber, these membranes possess exceptional water resistance capabilities and effectively safeguard submerged surfaces by forming a reliable seal. Whether it be a swimming pool, underwater tunnel, or offshore platform, the implementation of a waterproofing membrane can effectively thwart water ingress and preserve the structural integrity. Nonetheless, it is crucial to ascertain that the chosen waterproofing membrane has been meticulously crafted and thoroughly tested for underwater applications to guarantee optimal performance and longevity.

- Q: Can a waterproofing membrane be used on brick walls?

- Yes, a waterproofing membrane can be used on brick walls. It helps to prevent water penetration and protects the bricks from moisture damage.

- Q: Are waterproofing membranes suitable for below-grade applications?

- Waterproofing membranes are well-suited for below-grade applications, as they are specifically designed to prevent water infiltration into structures below ground level, such as basements, foundations, and retaining walls. These membranes are constructed using durable materials, capable of withstanding soil and water pressure, thus providing long-term protection against leaks and water damage. Typically, they are installed on the exterior side of below-grade structures to create a barrier that blocks water from permeating the walls or floors. Moreover, waterproofing membranes possess flexibility, allowing them to accommodate structural movements, ensuring their effectiveness even in challenging below-grade environments. In summary, waterproofing membranes serve as a dependable and efficient solution for safeguarding below-grade structures from water intrusion.

- Q: Can waterproofing membranes be used on concrete countertops?

- Yes, waterproofing membranes can be used on concrete countertops. These membranes are specifically designed to prevent water penetration and can be applied to various surfaces, including concrete. By using a waterproofing membrane on a concrete countertop, you can effectively protect it from water damage, staining, and potential structural issues. Additionally, these membranes can also enhance the durability and longevity of the countertop by preventing moisture-related issues such as cracking or warping. It is important to ensure that the chosen waterproofing membrane is compatible with concrete and suitable for countertop applications.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to protect surfaces from water penetration and damage. They are typically made of materials such as rubber, asphalt, or thermoplastic, which provide a barrier against moisture. Whether it is applied on interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane can effectively prevent water from seeping through and causing potential issues like leaks, mold, or structural damage. It is important to consider the specific requirements of each surface and choose a waterproofing membrane that is suitable for the intended application.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Yes, a waterproofing membrane typically requires specific preparation of the substrate before installation. The substrate, which is the surface on which the membrane will be applied, needs to be clean, dry, and free from any contaminants or debris that could hinder the adhesion of the membrane. This usually involves removing any loose materials, such as old paint or sealants, and smoothing out any uneven surfaces. Additionally, it may be necessary to repair any cracks or damage in the substrate to ensure a proper and effective installation of the waterproofing membrane. Following the recommended preparation procedures will help to maximize the performance and durability of the membrane, ensuring its effectiveness in preventing water penetration and protecting the underlying structure.

Send your message to us

Membran Weldable and Valcanization for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14000 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords