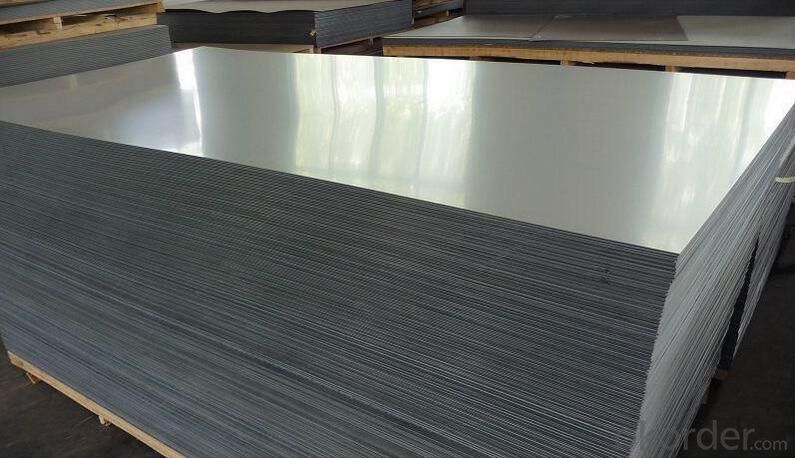

Matte Finish 1070 H18 Aluminum Mirror Sheets in Silver for Reflective Chimney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1070 H18 aluminum mirror sheets in silver for Reflective chimney

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: So my new farrier comes out tomorrow and charges $20 more for aluminum shoes and I was wondering why that is? Is one better than the other? My horse is a TB hunter jumper. Tell me what you think :)

- Like others have pointed out aluminum are lighter but more expensive and must be replaced more often, but they are also much lighter. When I am seriously competing I put aluminum shoes on my horses just for the summer show season to take advantage of the lighter weight, then back to steel for the rest of the year (and with steel being as durable as it is I can keep the same pair stored away to be put back on in the fall.) It's your call, its not a HUGE difference but it might help him pick his feet up better.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets can be suitable for electrical bus bars in certain applications. Aluminum has several properties that make it a viable option for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in applications where weight reduction is important. Additionally, aluminum has good electrical conductivity, although it is not as conductive as copper. However, aluminum bus bars can still handle high electrical currents and are commonly used in power distribution systems. One downside of aluminum bus bars is that they have a higher resistance compared to copper bus bars. This means that they can generate more heat, especially under high current loads. To mitigate this issue, aluminum bus bars are often designed with larger cross-sectional areas to reduce resistance and dissipate heat more effectively. Another challenge with aluminum bus bars is their susceptibility to oxidation and corrosion. This can be addressed by applying protective coatings or using alloys with better corrosion resistance. It is also important to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In summary, aluminum sheets can be suitable for electrical bus bars, especially in applications where weight reduction is important. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets are suitable for electrical bus bars. Aluminum is a lightweight and cost-effective material that exhibits good electrical conductivity. It is commonly used in various electrical applications, including bus bars, due to its ability to efficiently carry high electrical currents while dissipating heat effectively.

- Q: Are aluminum sheets resistant to chemicals?

- Aluminum sheets, in general, possess resistance to a wide range of chemicals. This is due to the presence of a natural oxide layer on the surface of aluminum, which acts as a protective shield against corrosion and chemical reactions. The stability of this oxide layer enables it to withstand the effects of most acids, alkalis, and organic solvents. However, it should be noted that certain chemicals, such as strong acids or bases, as well as some halogenated compounds, have the capacity to corrode aluminum. Moreover, prolonged exposure to particular chemicals or extreme conditions may compromise the integrity of the oxide layer, rendering aluminum more susceptible to corrosion. Consequently, when considering the use of aluminum sheets in specific applications, it is crucial to carefully evaluate the chemical environment and potential interactions.

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. It is a popular choice for roofing due to its lightweight, durability, corrosion resistance, and ability to withstand harsh weather conditions.

- Q: Is it possible to utilize aluminum sheets as materials for car body panels?

- <p>Yes, aluminum sheets can be used for car body panels. They offer several advantages such as lightweight, high strength, and good corrosion resistance. Aluminum is also easily recyclable and can be shaped into complex designs. However, aluminum is less resistant to dents compared to steel, which is a common material for car body panels. Despite this, aluminum's benefits often outweigh its drawbacks, making it a popular choice in the automotive industry, especially for high-performance and electric vehicles where weight reduction is crucial.</p>

- Q: Can aluminum sheets be used for solar panel applications?

- Yes, aluminum sheets can be used for solar panel applications. Aluminum is a lightweight and durable material that is commonly used for the frames and backings of solar panels. It offers good corrosion resistance and can efficiently dissipate heat, making it suitable for solar panel installations.

- Q: Are aluminum sheets suitable for architectural canopies?

- Yes, aluminum sheets are suitable for architectural canopies. Aluminum is a lightweight and durable material that offers excellent weather resistance and structural integrity, making it an ideal choice for canopies. It can be easily fabricated into various shapes and sizes, allowing for versatile and aesthetically pleasing designs. Additionally, aluminum can be coated or anodized to enhance its appearance and protect it from corrosion, further enhancing its suitability for architectural canopies.

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- Strange... okorder /

- Q: Can aluminum sheets be used for insulation purposes?

- Yes, aluminum sheets can be used for insulation purposes. Aluminum has a high thermal conductivity, which means it is a good conductor of heat. However, when used for insulation purposes, aluminum sheets are typically combined with other materials to create a more effective insulation system. One common example is aluminum foil insulation, where a layer of aluminum foil is combined with other materials such as foam or fiberglass to create a barrier against heat transfer. The reflective properties of aluminum also make it useful for reflecting radiant heat, further enhancing its insulation capabilities. Overall, while aluminum sheets alone may not provide sufficient insulation, they can be used effectively in combination with other materials to create insulation systems for various applications.

Send your message to us

Matte Finish 1070 H18 Aluminum Mirror Sheets in Silver for Reflective Chimney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords