Color Aluminum Pyramid Corrugated Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COLOR COATED ALUMINUM COIL

Product Description:

CNBM uses the advanced Roller Coating Technology, Digtal color print and numberous controlling position technology, degrease, clean, chromated on single/duplicate surface of the aluminium coil. Then wooden Veins & stone Veins come out lively. It has outstanding advantage.

You can use that roller coils for ceiling panel, aluminium panel and honeycomb panel for decoration. For several years' development and design.

PE and PVDF coating.

Aluminium alloy 1100,3003,3105,5005 and others.

Diamond Embossed coil and anti-scratch coil are available.

Product Usage:

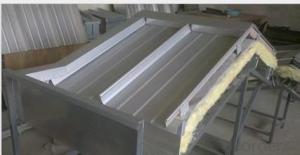

1) exterior applications: wall cladding, facades, roofs and canopied, tunnels, column covers or renovations.

2) Interior application: wall cladding, ceilings, bathrooms, kitchens and balconies.

3) Advertisement and market applications: display platforms, signboards, fascias and shop fronts.

4) Transport and industrial applications.

Specification:

1) Alloy:1100, 3003,3005,3105,5005 and others

2) Thickness:0.02-3.0mm.

3) Width: 50-1500mm.

4) Coating: PE coat

PVDF coat

5) Color standard: E<2 or unperceivable by eye

6) Pencil hardness: >2HB

7) Coating Adhesive: Not lower than first grade impact: no crack(50kg/cm, ASTMD-2794:1993)

8) Buketon: >100 times

9) Boiling point: no distortion and color change

10) Packing: Export standard: Packed in wooden case, wrapped with Foam, Plastic Membrane and Kraft paper

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Aluminum sheets have the ability to undergo anodization for the purpose of aesthetics. Anodization is an electrochemical procedure that forms a protective oxide layer on the surface of the aluminum. This layer has the potential to be colored in a variety of shades, thus offering a wide range of aesthetic possibilities. Anodized aluminum sheets are highly sought after in the field of architecture, particularly for constructing facades, due to their enduring and visually pleasing appearance. Furthermore, the anodized layer bolsters the aluminum's resistance to corrosion and wear, making it suitable for both indoor and outdoor applications. Moreover, anodized aluminum sheets can be subjected to additional processes like etching or laser engraving, enabling the creation of intricate designs and patterns.

- Q: What are the different surface finishes available for aluminum sheets?

- Some of the different surface finishes available for aluminum sheets are mill finish, brushed finish, anodized finish, and embossed finish. Mill finish is the natural appearance of the aluminum without any additional treatment. Brushed finish involves brushing the surface to create a textured appearance. Anodized finish involves an electrolytic process that forms a protective layer on the surface and can be colored. Embossed finish involves creating patterns or designs on the surface using pressure or heat.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of high-rise buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in high-rise buildings. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. Aluminum sheets can also be coated or anodized to provide additional protection and aesthetic appeal. They are often used in combination with other materials or as a cladding system to enhance the building's appearance and energy efficiency.</p>

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Yes, aluminum sheets are widely used in aircraft manufacturing due to their lightweight, high strength-to-weight ratio, excellent corrosion resistance, and good formability.

- Q: What are aluminum sheets?

- Aluminum sheets are thin flat pieces of aluminum that are commonly used in various industries for applications such as construction, automotive manufacturing, packaging, and aerospace. They are versatile, lightweight, and durable, making them ideal for a wide range of purposes.

- Q: Can aluminum sheet be used for automotive body panels?

- Yes, aluminum sheet can indeed be used for automotive body panels. Aluminum is a lightweight and corrosion-resistant material, making it desirable for improving fuel efficiency and increasing vehicle performance. It is widely used in the automotive industry to manufacture body panels, such as hoods, doors, fenders, and roofs, as it offers strength, durability, and design flexibility.

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- 12 Ft Aluminum Boats

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. Aluminum is a widely used material in the pharmaceutical industry due to its various beneficial properties. Firstly, aluminum sheets are lightweight and have excellent corrosion resistance. This makes them ideal for packaging pharmaceutical products as they can protect the contents from external factors such as moisture, light, and oxygen, which could potentially degrade the quality of the medication. Additionally, aluminum sheets can be easily formed into different shapes and sizes, allowing for customization in packaging design. They are also available in various thicknesses, providing options for different types of pharmaceutical products, from tablets and capsules to liquid medications. Furthermore, aluminum sheets have a high barrier property, effectively preventing the transfer of odors, flavors, and contaminants. This ensures the integrity and safety of the medication throughout its shelf life. Moreover, aluminum is a non-toxic material, which means it does not react with drugs or alter their composition. This makes it a suitable choice for pharmaceutical applications, where maintaining the purity and stability of the medication is crucial. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications due to their lightweight, corrosion resistance, barrier properties, and non-toxic nature. They provide efficient protection and preservation of pharmaceutical products, ensuring their quality and safety.

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

- Q: Are aluminum sheets suitable for automotive heat shields?

- Certainly! Automotive heat shields can indeed utilize aluminum sheets. Aluminum is an exceptional option for heat management in automotive applications due to its lightweight nature and impressive conductivity. Its high melting point and excellent thermal conductivity properties allow it to efficiently absorb and disperse heat produced by the vehicle's engine, exhaust system, and other heat sources. Furthermore, aluminum sheets are easily moldable and can be crafted into diverse sizes and designs, making them adaptable for various automotive heat shield purposes. In summary, aluminum sheets offer an economical and effective means of safeguarding vulnerable components from heat-related harm within automotive systems.

Send your message to us

Color Aluminum Pyramid Corrugated Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords