Geocells for Erosion Control - Polypropylene Geogrid with Low Elongation and Good Toughness for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

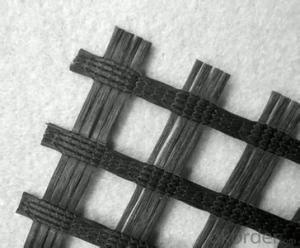

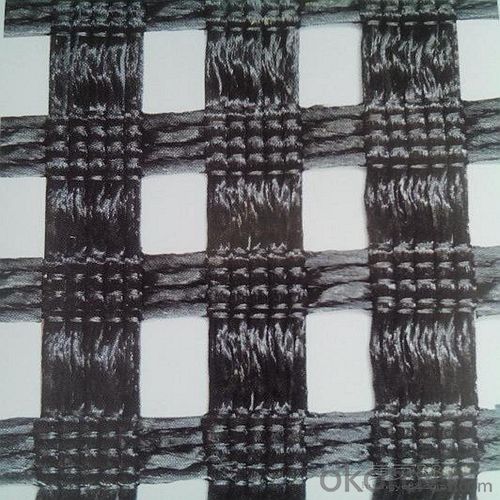

Geogrid

Warp Knitted geogrid is made from high-strength fibers( polyester fiber or glass fiber), can also call high-strength fibers geogrid. This kind of use strength polymer or glass fiber as material, which woven by weaving machine to be with foursquare holes called warp knitted geogrid which arranged in parallel of latitude and longitude. According to customer demand, could composite geotextile or other kind of material.

Main applications:

Road bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

It can be withstand greater alternating load

It can prevent road bed deformation and breakage caused by loss of road bed material

By increasing the self-load bearing capacity of backfill behind the retaining wall,it can reduce the load on retaining wall,save cost,extend its useful life and lower maintenance cost.

Combined with slope maintenance using shotcrete,it can not only save cost by 30% to 50% but also shorten construction duration by half

By adding geogrid in the road bed and bass course,it can reduce curve settlement,lessen traffic tracks,delay the occurrence of cracks by 3 to 9 times the normal period and reduce the thickness of structural course by 36%

It is suitable for all types of soil and all material is available locally

It is convenient in application and may significantly reduce construction cost.

Porducts Description

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

Material:

Fiberglass

Tensile strength:

100kn

Roll Width:

3.95m

Roll length:

100 Meter

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Do geogrids require maintenance?

- Yes, geogrids do require maintenance. Regular inspections should be conducted to ensure that the geogrids are properly installed and functioning as intended. Depending on the specific application and environmental conditions, maintenance activities may include removing debris, repairing any damage, and monitoring for any signs of failure or degradation.

- Q: What is the recommended spacing between geogrid layers?

- The recommended spacing between geogrid layers can vary depending on the specific application and design requirements. However, in general, a spacing of about 1 to 2 feet (30 to 60 centimeters) is often recommended. This allows for proper interlocking and interaction between the geogrid layers, ensuring optimal load distribution and stability. It is important to consult with a geotechnical engineer or follow the manufacturer's guidelines to determine the appropriate spacing for a particular project.

- Q: How do geogrids improve the performance of mechanically stabilized walls?

- Geogrids improve the performance of mechanically stabilized walls by providing reinforcement and enhancing the stability of the wall structure. They act as a support system, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids distribute the loads exerted on the wall more evenly, reducing the pressure on the wall face and minimizing the risk of structural failure. Additionally, they enhance the overall durability and longevity of the wall system by preventing soil erosion and promoting proper drainage.

- Q: EG90R what is the geogrid material?

- One way pull plastic geogrid, also called one-way plastic geogrid

- Q: Can geogrids be used in erosion control on slopes and hillsides?

- Yes, geogrids can be used in erosion control on slopes and hillsides. Geogrids are designed to reinforce and stabilize soil, preventing erosion and improving slope stability. They are commonly used in various erosion control applications, including on slopes and hillsides, to enhance the structural integrity of the soil and reduce the risk of erosion.

- Q: How do geogrids improve the performance of geotextile sediment retention systems?

- Geogrids improve the performance of geotextile sediment retention systems by providing reinforcement and stability. They enhance the overall strength and durability of the system, preventing soil erosion and retaining sediment effectively. Additionally, geogrids help distribute load and reduce stress on the geotextile, increasing its lifespan and effectiveness in retaining sediments.

- Q: How do geogrids improve the performance of geosynthetic encased columns?

- Geogrids improve the performance of geosynthetic encased columns by providing additional reinforcement and stability. They enhance the load-bearing capacity of the columns, increase their resistance to lateral movements, and distribute the forces more evenly throughout the structure. Geogrids also help to prevent soil erosion and provide long-term durability to the columns, ultimately improving their overall performance.

- Q: Can geogrids be used in soil reinforcement for load-bearing platforms?

- Yes, geogrids can be used in soil reinforcement for load-bearing platforms. Geogrids are commonly used in civil engineering projects to improve the stability and strength of soil. They are effective in distributing loads, reducing soil settlement, and preventing soil erosion, making them suitable for reinforcing load-bearing platforms.

- Q: Are geogrids suitable for reinforcement of mechanically stabilized earth retaining walls?

- Yes, geogrids are suitable for the reinforcement of mechanically stabilized earth retaining walls. Geogrids are specifically designed to provide strength and stability to soil structures, and they effectively distribute and transfer loads within the soil mass. By adding geogrids to a mechanically stabilized earth retaining wall, the overall structural integrity and resistance to lateral forces can be significantly enhanced, making them a reliable and effective solution for reinforcement.

- Q: Each side of geogrid is not less than 3 meters, what does it mean?

- If each side is folded three meters, then it is folded

Send your message to us

Geocells for Erosion Control - Polypropylene Geogrid with Low Elongation and Good Toughness for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords