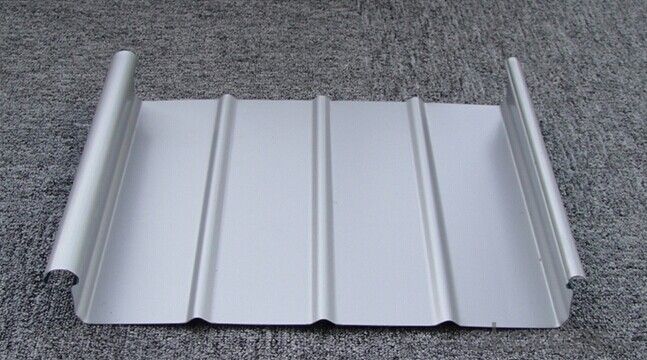

Magnesium manganese roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colorful stone coated steel roof tile( colorful tile), is a kind of international fashion,fill the domestic blank new high-tech roofing construction materials,It is made of metal and polymer and nonmetallic material compound,with new structure. From top to bottom section for acrylic paint, color TaoHua natural stone, acrylic resin coating, Al - Zn aluminium zinc coating, the steel basic, Al - Zn aluminium zinc coating, resin coating.

Due to the above materials and structure characteristics, it has high strength, high corrosion resistance, high elastic modulus, light weight, energy-saving, environmental protection, etc. Both have the clay, cement traditional roofing tiles and caigang tiles, fiberglass asphalt roofing tile all the advantages, beautiful appearance,massiness, texture,frivolous, can rise already building roof adornment quality,and can reduce the engineering material consumption and load.This is euramerican developed countries in the early 1990s until the invention and began to use, because of its beautiful, light, durable, environmental protection, has become the mainstream products and the first using roofing material, many domestic real estate project also begin to using it in recent years.

3000 series Al-Mn-Mg aluminum alloy on the basis of the metal with the composition of the Mn-Mg alloy plate of this elongation, hardness, tensile strength, yield strength is more suitable for roofing and other indicators curling, rolling pressure processing equipment, It is widely used in roofing, wall systems and other building exterior maintenance projects, and with the various paint systems and coating process to make more colorful appearance, but also increased the corrosion resistance of aluminum itself.

- Q: How is steel recycled in construction?

- Steel is commonly recycled in construction through a process called "downcycling." This involves collecting and sorting steel materials from demolished structures, such as buildings and bridges. The collected steel is then transported to recycling facilities where it is melted down and reshaped into new steel products, such as reinforcement bars or structural beams. This sustainable practice not only reduces the need for virgin steel production but also helps conserve valuable resources and minimize waste in the construction industry.

- Q: How are steel structures designed to accommodate for future expansion or modifications?

- To ensure adaptability and flexibility, steel structures are specifically designed to allow for future expansion or modifications. One common method utilized is the incorporation of modular construction techniques. This involves designing the structure in sections or modules that can be effortlessly disassembled and reassembled to accommodate future changes. Another approach is to design the steel structure with clear span frames. Clear span frames eliminate the need for interior columns or supports, providing unobstructed interior space. This design feature allows for easy reconfiguration of interior spaces without any structural constraints. Furthermore, steel structures can be designed to handle additional loads by considering potential future loads, such as extra floors or equipment. The structure is designed to accommodate these loads without compromising its integrity, ensuring it is well-equipped for increased loads when expansion is required. Additionally, steel structures can include extra structural connections or strategically placed openings to facilitate future modifications. These connections or openings are designed to allow for the addition or alteration of structural elements, such as beams or columns, making it simpler to modify or add sections to the structure. Moreover, steel structures can incorporate flexible design features like adjustable or removable walls, partitions, or roof elements. These features enable easy reconfiguration of interior spaces or expansion without the need for major structural modifications. In summary, the design of steel structures for future expansion or modifications involves careful consideration of modular construction techniques, clear span frames, additional load-bearing capacity, strategic structural connections or openings, and flexible design features. By incorporating these elements, steel structures can easily adapt to accommodate future changes, ensuring their longevity and functionality.

- Q: What is the purpose of steel columns in structures?

- The purpose of steel columns in structures is to provide vertical support and stability, distributing the weight of the structure evenly and efficiently. They help to transfer loads from the upper levels to the foundation, ensuring the overall structural integrity and safety of the building. Steel columns are strong, durable, and can withstand heavy loads, making them a popular choice in construction.

- Q: What are the cost considerations of using steel in structures?

- When considering the use of steel in structures, there are several cost factors to take into account. First and foremost, the initial cost of steel itself tends to be higher compared to other construction materials like wood or concrete. This is due to the extensive processing and fabrication required to manufacture steel, which contributes to its higher price. However, incorporating steel into structures can lead to cost savings in the long run. Steel is renowned for its durability and strength, enabling the creation of lighter and more efficient structures. As a result, less material is needed for construction, leading to reduced transportation and labor costs. Furthermore, steel structures have a longer lifespan than structures made from other materials. Steel is resistant to decay, pests, and weathering, which means it requires less maintenance and repair over time. This translates to significant cost savings in terms of ongoing maintenance and replacement. Additionally, steel structures offer flexibility in design and construction, allowing for greater architectural freedom and creativity. The ability to prefabricate steel components off-site can expedite the construction process, saving both time and money. Lastly, steel structures exhibit high resilience to seismic activities and extreme weather conditions. This can result in lower insurance premiums and a decreased risk of damage during natural disasters. In conclusion, although the initial cost of using steel in structures may be higher, the long-term considerations of durability, efficiency, reduced maintenance, and flexibility make it a cost-effective choice in many construction projects.

- Q: How are steel structures used in the construction of stadiums?

- Steel structures are commonly used in the construction of stadiums due to their strength, durability, and versatility. Steel beams and columns provide the necessary support for large spans, allowing for the creation of expansive open spaces within stadiums. Additionally, steel is lightweight, making it easier to transport and assemble on-site. This material is also resistant to fire, corrosion, and seismic activities, ensuring long-lasting and safe structures. From the framework to the roof and seating areas, steel is utilized in various aspects of stadium construction, enabling the creation of iconic and iconic sports venues worldwide.

- Q: How do steel structures provide resistance against wind-induced vibrations?

- Steel structures provide resistance against wind-induced vibrations through their inherent strength and stiffness. The use of steel as a construction material allows for the creation of highly rigid frames and beams, which can effectively resist the forces exerted by wind. Firstly, steel has a high tensile strength, meaning it can withstand large amounts of tension without deforming or breaking. This property enables steel structures to absorb and distribute the wind forces evenly throughout the entire structure, preventing localized areas from experiencing excessive stress. By efficiently transferring these forces, steel structures minimize the risk of vibration-induced damage. Additionally, steel possesses excellent stiffness properties, meaning it is resistant to deformation under load. This stiffness allows steel structures to maintain their shape and stability, even when subjected to high wind pressures. The rigidity of steel members reduces the likelihood of excessive deflection or swaying, thereby minimizing vibrations caused by wind. Moreover, steel structures can be engineered with specific design features to further enhance their resistance against wind-induced vibrations. These include diagonal bracing, which can be strategically placed to increase the overall stiffness of the structure and reduce its susceptibility to vibrations. By providing additional support and reinforcing critical areas, diagonal bracing helps to effectively dampen any potential oscillations caused by wind. Furthermore, steel structures are often designed with aerodynamic considerations in mind. The streamlined shapes and smooth surfaces of steel buildings help to reduce wind resistance and minimize the creation of turbulent airflow around the structure. By minimizing the impact of wind pressure, these design features reduce the chances of wind-induced vibrations occurring in the first place. In summary, steel structures provide resistance against wind-induced vibrations by utilizing their inherent strength, stiffness, and specific design features. The high tensile strength and stiffness of steel allow for the efficient distribution of wind forces, preventing localized stress and minimizing vibrations. Additionally, features such as diagonal bracing and aerodynamic design further enhance the ability of steel structures to resist wind-induced vibrations, ensuring their stability and integrity.

- Q: How does steel perform in terms of vibration control?

- Steel performs well in terms of vibration control due to its high stiffness and density. It has the ability to dampen vibrations and reduce resonance, making it an effective material for applications where vibration control is important, such as in construction, machinery, and automotive industries. Additionally, steel's excellent strength and durability allow it to withstand dynamic loads and vibrations without significant deformation or fatigue, further enhancing its performance in vibration control.

- Q: How do steel structures perform in extreme temperatures?

- Steel structures generally perform well in extreme temperatures. Steel has a high melting point, making it resistant to heat, and it maintains its strength and structural integrity in both high and low temperatures. However, extreme temperature variations can lead to expansion and contraction of the steel, which may cause some issues if not properly accounted for in the design and construction process. Overall, when designed and constructed appropriately, steel structures can withstand extreme temperatures effectively.

- Q: How are steel structures designed and constructed to meet specific architectural requirements?

- Steel structures are designed and constructed to meet specific architectural requirements through a comprehensive and meticulous process. Firstly, the architectural requirements are thoroughly analyzed, including factors such as the purpose of the structure, the desired aesthetics, and the functional needs of the building. Once these requirements are clearly defined, the design phase begins. During the design phase, engineers and architects collaborate to create a structural design that fulfills the architectural requirements. This includes determining the load-bearing capacities, the size and placement of columns and beams, and the overall layout of the structure. Advanced computer-aided design (CAD) software is often used to create 3D models and simulations that help visualize and refine the design. Steel, being a highly versatile and durable material, is often the preferred choice for structural elements in architectural designs. It offers excellent strength-to-weight ratio, allowing for the creation of large and open spaces with minimal obstructions. The steel members are carefully selected based on their properties and then incorporated into the design. Once the design is finalized, the construction process begins. The steel structure is fabricated off-site in specialized factories, where the steel members are manufactured according to the design specifications. This ensures precision and quality control. The fabricated parts are then transported to the construction site for assembly. During the construction phase, the steel members are erected and connected using various techniques such as welding or bolting. Skilled labor, including ironworkers and welders, play a crucial role in ensuring the accurate and safe construction of the steel structure. The construction process also includes the installation of other components like flooring, roofing, and cladding, which are integrated with the steel structure. To meet specific architectural requirements, additional architectural elements may be incorporated into the steel structure. These can include features like curved or cantilevered sections, unique facade systems, or specialized finishes. These elements are carefully integrated into the design and construction process to ensure they are structurally sound and aesthetically pleasing. Throughout the entire design and construction process, compliance with relevant building codes and regulations is essential. Structural engineers ensure that the steel structure meets all safety standards and can withstand the expected loads and environmental conditions. Additionally, regular inspections and quality control measures are implemented to ensure the durability and longevity of the steel structure. In conclusion, steel structures are designed and constructed to meet specific architectural requirements through a meticulous process that involves careful analysis, precise design, and skilled construction. By utilizing the versatility and strength of steel, architects can create innovative and functional structures that meet the desired aesthetic and functional goals.

- Q: How are steel structures affected by extreme weather conditions?

- Steel structures are generally resilient to extreme weather conditions. They can withstand high winds, heavy snow loads, and even earthquakes. However, prolonged exposure to corrosive elements, such as saltwater or acidic rain, can cause rust and deterioration over time. Regular maintenance and proper protective coatings can mitigate these effects and ensure the longevity of steel structures.

Send your message to us

Magnesium manganese roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords