Loop Tie Wire/ Binding Wire with Good Quality Factory Direct Lower Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

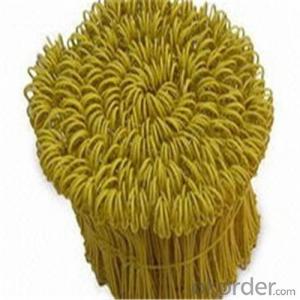

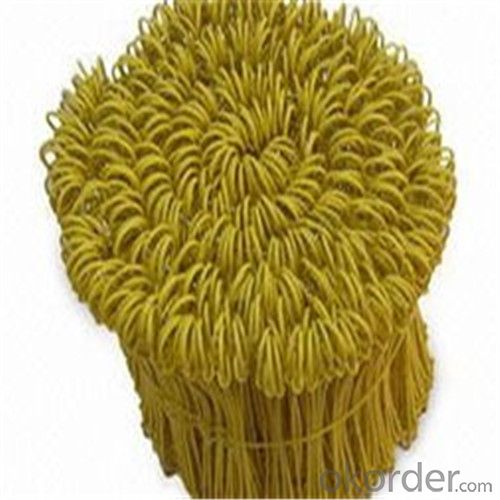

1.Structure of Looped Tie Wire Description:

Looped Tie Wire is also known as tie wire or binding wire. It is easy to operate, therefore it's widely uses in binding of different materials, especially for daily use. The main materials of loop tie wires are galvanized iron wire, black annealed iron wire, PVC-coated iron wire and copper wire.

Looped Tie Wire is coated with PVC to create a strong, easy-to-use twist wire tie. PVC coating will not crack, chip or scratch off when tying; meantime this coating provides protection against rust and corrosion. It is widely used for tying and support of plants in gardens or other binding uses, such as tying of sacks and other bagging. This kind of wire is also widely used in securing the position of reinforcing bars during concrete placement.

2.Main Features of Looped Tie Wire:

• Durable

• Practical

• Convenient

• Use widely

• Inexpensive

• Soild

3. Looped Tie Wire Images

4.Looped Tie Wire Specification

Wire Gauge | SWG in mm | BWG in mm | In Metric System mm |

8# | 4.06 | 4.19 | 4.00 |

9# | 3.66 | 3.76 | |

10# | 3.25 | 3.40 | 3.50 |

11# | 2.95 | 3.05 | 3.00 |

12# | 2.64 | 2.77 | 2.80 |

13# | 2.34 | 2.41 | 2.50 |

14# | 2.03 | 2.11 | |

15# | 1.83 | 1.83 | 1.80 |

16# | 1.63 | 1.65 | 1.65 |

17# | 1.42 | 1.47 | 1.40 |

18# | 1.22 | 1.25 | 1.20 |

19# | 1.02 | 1.07 | 1.00 |

20# | 0.91 | 0.89 | 0.90 |

21# | 0.81 | 0.813 | 0.80 |

22# | 0.71 | 0.711 | 0.70 |

23# to 34# also available for galvanized iron wire. | |||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

As a professional manufacture with many years of experiences, we have advanced facilities for production, and most of the products, like Loop tie wire. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②Can we get samples?

Yes, we'd like to send you free samples for your test.

③How long can we receive the product after purchase?

In the purchase of Loop tie wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Me and a buddy took the 305 out of the car. I have a 350 to take its place, but was wondering what are the only wires i need to have a clean engine bay. the old engine has a million wires hooking up to everything. Some muscle cars only have spark plug wires, the starter wire and battery cable. What must i do to get mine like that? i dont care about emissions. what must i change or add to the new engine?

- I have an '84 Monte SS and wanted the same thing. Here's what I have: the 2 wires that come from the harness and go to the starter (1 Positive, 1 S terminal), oil gauge wire, temp gauge wire, the alternator wires, the wire going to the distributor cap, and the tach gauge wire going to the distributor cap. That's pretty much it, as well as your battery cables, and spark plug wires. You really don't need to do or add anything as long as it runs and everything works that needs to work, it'll be fine. I'm going by memory, so if I forgot something I apologize, but that's the best of my recollection right now. If you have anymore questions you can email me.

- Q: i got this switch with numbers 1 , 2, 3, and 4 on it and 4 wires red, green, and two black. Which wires go to which number?

- Well it is defintely a 3 way switch. The fourth (green) wire being the ground. I can't tell you by the numbers, but I can tell you by the screws which wire goes where. If it does not apply to your switch you may need to go get a new one. They are inexpensive. The green, ground wire goes to the screw that is usually attached to the arms ( metal extentions that hold against the sheet rock. Now you need to find the red and black wire that are together. Look inside the box where the wires come in and you should be able to tell if the red and black are in the same sheathing. These are your travelers. The travelers need to go on the two screws that are across from eachother. One goes on the right side and one goes on the left. Does not matter which side. The last black wire, depending on which of the two 3 ways you are at is either your power or your light leg (wire going to your light). This wire goes on the last screw. Hope this was helpful.

- Q: I made a kill switch for my car. All I need to do now is cut the wire that goes into my engine control module and join it with the switch I made. Would it be fine if I just use wire nuts or some sort of tape to join the wires instead of soldering? The instructions say quot;Step 6: Attach the killswitch wires one to each side of the wire you just cut. Step 7: Tape up all new connection.quot;It says to tape the new connections, but should I use exactly?

- Twisted wires can separate with the daily rattle and bumps of a car. I would crimp or solder it along with a shrink tube to secure it.

- Q: What silk is fine as hair, soft as wool, strong as steel?

- Characteristics of molybdenum wire:Ultra high tensile strength;It has high surface finish, good stability and high cutting accuracy;Elongation rate is small, tight silk is small;The winding rate is large, the wire diameter is uniform, it is difficult to break the wire, and the service life is long;Increase the high frequency power and improve the rough machining efficiency;The accurate measurement, vacuum packaging, prevent oxidation mildew, can be stored for a long time.Remember, the smallest one is only half a millimeter. It's very, very thin. One second you can cut down 1 trees. Of course, it depends on whether the equipment supports it!

- Q: My telephone doesn't work. No Dial tone. When I plug the phone into the box outside the phone works so that tells me it is the wiring going into or in the house. The phone repairman put in a new phone box outside because the old one wasn't accessible anymore (we accidentally built a porch over it) when he did that he spliced the wire going from the old box to the new box. The wires that he spliced hang down under the porch. There are 4 wires coming out of each wire, but only two are spliced together. Should the other two be spliced also? I'm thinking maybe they were but my dog has messed with them. The phone service went down all of the sudden and I don't really know anything else to check. Any ideas?

- each phone line uses a pair of wires (2 wires) these wires would normally be green/red or blue/white and solid blue for line 1 and if needed yellow/black or orange/white and solid orange for line 2... you did the first step in troubleshooting to know that the trouble resides inside your home... so when you call into your line does the phone ring busy (or go straight to voice mail) or does it just keep ringing.... if it rings busy (or straight to VM) then there is a short on the line... this is possibly a defective phone, a phone that is off the hook, or a bad jack or wire... if the phone just keeps ringing, then there is a broken wire somewhere...... since the old NID is no longer accessible, you may need to run a section of wire from the new NID to one of the existing jacks in your home to back feed the jacks... if you do this i recommend disconnecting the wire that is going from the new NID to the old NID, as if you reverse the polarity you may end up shorting out your line with the new wire...

- Q: I recently bought a stereo for my truck. What is a good average gage for a ground wire? Speaker wire? Power wire? Last but not least a speaker control (remote) wire? If it helps, I am running a 760 watt pioneer amp on two 12 inch subs. Thanks

- You should run at least 10 Gage power and ground wires. I would recommend 14 Gage speaker wire.

- Q: Its a 3 wire chandelier, 2 are attached like a regular electric cord and the third is separate. all are the same color. the ceiling has 2 wires. one tan/white and the other is red. I am comfortable with doing the connections but unsure what wires to connect

- One of the chandelier wires will go to the red and the other to the white wire--it does not matter which one goes to which. The third wire is likely bare (or green) and is a ground wire. Connect this wire to the ceiling box and to the third wire in the ceiling if there is one.

- Q: im hooking a amp up and i need to run my remote wire to my ignition wire

- I have wired up alot of amps and the remote wire on the amp should be connected to the power antenna/amp turn on wire on the stereo head unit. This allows the amp to only turn on when the stereo is on. If you are connecting an amp to a factory stereo,I see why you would need to find an ignition wire. You need to probe the fuse panel with a 12 volt test light to find a circuit that only comes on with the key. Usually there is a spare accessory fuse location just for this. Buy a fuse tap or specialty fuse from a auto parts store to connect your remote wire to. There is very little current draw to turn on the amp,so almost any circuit on the fuse panel will work if it is only on with the key.

- Q: Does anyone have a schematic?

- on the wires it should tell you want the wires are four you should have a red wire black wire.the red is live wire and the back wire is earth wire.and the four you got left is speaker wires

- Q: subs - dvc 4ohm 2 of them 600wattrms on each wiring it to a 1200 watt amp same brand as sub amp is 1 ohm stable to i wire the subs together and then to the amp a 1ohm? that would give each sub 600 watts right?

- no wat i would do is wire 1 speaker to 1 port and wire the other speaker to the other pot thats if it is a 2 chanel amp... cause if not u will be pulling to much from 1 side and the speakers wont sound right..... u need to turn down the amp to at first and then bring up the bass gradually to make sure the speakers can handle it..... u also have the choice to bride the amp but thats it the spakers can handle the power... all u have to do is hook up positive then negative to 1 speaker the hook up positive then negative to a diffrent speaker but it has to be from a diff channel...... but if ur going to bridge the speakers then u go positive from 1 port to the negative to the negative of the other port this will give u alot more power to ur speakers.... thats why i recomend u hooking them up regular at first........... u also have to make sure ur gornd is like a foot long or less.... the shorter the ground the more the bass

Send your message to us

Loop Tie Wire/ Binding Wire with Good Quality Factory Direct Lower Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords