Loop Tie Wire/ Binding Wire Packing Bind Wire High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Looped Tie Wire Description:

Loop tie wire is easy-to-use twist wire tie and it is coating provides protection against rust and corrosion. Fine grains, adjust, eliminate defects than ordinary black iron wire is more soft, better flexibility, softness and uniform, consistent color is mainly used in construction mining chemical welding net hangers rework after annealed wire become soft, flexible, construction tie wire binding reinforcement effect more.

Loop tie wire is widely used for tying and support of plants in gardens or other binding uses, such as tying of sacks and other bagging. This kind of wire is also widely used in securing the position of reinforcing bars during concrete placement.

2.Main Features of Looped Tie Wire:

• Durable

• Practical

• Convenient

• Use widely

• Inexpensive

• Soild

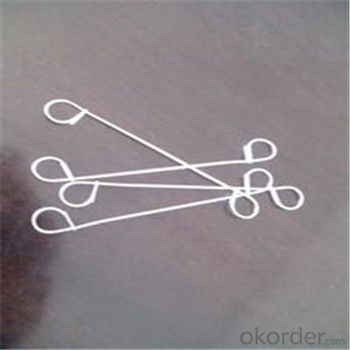

3. Looped Tie Wire Images

4.Looped Tie Wire Specification

Wire Gauge | SWG in mm | BWG in mm | In Metric System mm |

8# | 4.06 | 4.19 | 4.00 |

9# | 3.66 | 3.76 | |

10# | 3.25 | 3.40 | 3.50 |

11# | 2.95 | 3.05 | 3.00 |

12# | 2.64 | 2.77 | 2.80 |

13# | 2.34 | 2.41 | 2.50 |

14# | 2.03 | 2.11 | |

15# | 1.83 | 1.83 | 1.80 |

16# | 1.63 | 1.65 | 1.65 |

17# | 1.42 | 1.47 | 1.40 |

18# | 1.22 | 1.25 | 1.20 |

19# | 1.02 | 1.07 | 1.00 |

20# | 0.91 | 0.89 | 0.90 |

21# | 0.81 | 0.813 | 0.80 |

22# | 0.71 | 0.711 | 0.70 |

23# to 34# also available for galvanized iron wire. | |||

5.FAQ

①How about your Looped Tie Wire?

Our company is a professional manufacturer of wire in China. The mainly product is Galvanized Iron Wire and Looped Tie Wire. We export 30000 tons wires and wire mesh all over the world. We can offer high qulaity products with competitive price.

②What is our service?

1).Be promptly to reply each inquiry within 5 hours;

2).Quality controlled in the factory from sample to mass production;

3).Keep on service until the goods arrive to customers;

4).After-serive in time to save your time.

③How long can we receive the product after purchase?

In the purchase of Looped Tie Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days is suitable.

- Q: does it matter what gauge speaker wire to use when hooking up a powered subwoofer?

- actual confident, the speaker twine could desire to continually be twelve gauge exceptionally in case you go with crystal-sparkling sound. and you could desire to get 4 gauge potential and floor wires besides. They sell great high quality audio cables at Walmart.

- Q: I am replacing an electrical outlet that currently has 3 white and 3 black wires plus the ground wire. The bad outlet has 3 holes already in it for each of the wires but my new outlet does not, there are only 2 holes and/or the 2 screw on each side. How do I install this new outlet? Do I need to do the pigtail here?

- This Site Might Help You. RE: How to replace electrical outlet 6 wires? I am replacing an electrical outlet that currently has 3 white and 3 black wires plus the ground wire. The bad outlet has 3 holes already in it for each of the wires but my new outlet does not, there are only 2 holes and/or the 2 screw on each side. How do I install this new outlet? Do I need to do...

- Q: My friend is buying under-wired bras and what are they and the heavily- wired bra?

- It just means they have a wire underneath the cup to keep the bra from sagging. Everyon past 16 wears them.

- Q: (For my PC)I want to have a quadrophonic speakers (4 channels), but i want to extend 2 speakers, but their wires are limited and cant extend enough to reach my rear? what should i do?is it as simple as, cut the speaker wires and extend it with a common copper wire that you mostly found on most appliance you found on your home?

- It would be best to replace the short wire with new wire of the proper length! Use speaker wire, it will cost less and that's why it's made! But, what you said would work, most likely!

- Q: Would crepe paper stick on chicken wire?

- Crepe paper needs an adhesive to make it stick to a surface, such as white glue. However, it gets messy once dampened, as the colors may bleed. Instead, I would consider working with paper mache or plaster gauzing strips, which would provide a strong skin over the chicken wire. Both can be primed with gesso then decorated with acrylic paints. If this is a sculptural piece you want to keep, we would also suggest varnishing it for protection.

- Q: coil wiring diagram

- The two small wires are positive and negative. Most are color coded and if it's a OEM part, the negative will be the same color as the group of smaller wires connected to the negative battery cable. Each manufacturer uses different color codes and for instance, Kawasaki uses black with yellow stripe. The other wire will go to the positive side. If the coil doesn't have wire coming out if it, it may have a + or - sign by the terminals. In actuality, it doesn't really matter which way you hook it up because a coil doesn't really care which way the electricity travels. It's the collapsing magnetic field that creates the spark and not the direction or movement of electricity.

- Q: I understand how to wire sprinkler valves in theory. But in practice, how is it done. For instance, starting at the last valves in the run, the common wire is attached, but in a 7-strand wire, you may only use 3 colored wires or so. What do you do with the unused wires? Just leave them dangling? Cap them off with a grease cap? Then, as you arrive at the next set of valves, do you cut the entire strand and splice, or just cut out the individual colored wires that you need to wire those valves?

- As general practice (GP), phone company technicians wrap the extra wires around the end of the cable (both ends). This keeps them out of the way, yet they are there for later use, if necessary.

- Q: I have a 3 wire source I want to connect it to a switch on/off and then make it 2 wire to the light

- Is the 3rd wire bare or green? And the first response you received is from a automotive electrician DO NOT TAKE THAT ADVICE automotive wiring is backwards from AC residential wiring. You can e-mail me or one of the other sparky's on this site for help just click our profiles and read the answers to verify our qualifications. Then click contact.

- Q: The wires I have are: 1 red starter cable, 1 tan wire, 1 ground wire to the engine block, 1 red wire to the battery, and 1 red wire that splits into the fuse and into the junction strip. Really need to know which wires go where on the solenoid.

- The tan wire is the overtemp warning horn, should have a flat connector on it, connect it to the temp switch near the top of the cylinder head at the back. solenoid has four terminals, 2 large, 2 small. 1 large terminal gets the battery (+) cable *and* the red wire with the inline fuse (it provides +12V to the keyswitch), the other split end gets juice from the alternator for charging the battery. On the terminal strip, it should hook up to red wire coming from the rectifier (small metal canister-shaped device). It's best to secure the battery cable with a nut, then the red wire with a second nut. The other large terminal gets the cable from the starter positive terminal. 1 small terminal gets the white wire from the main wiring harness plug (it's the start circuit), and the other small terminal gets grounded -- just run a black wire from there to any good engine block ground. The small terminals actuate the solenoid, closing the circuit between the battery and the starter motor. To test the overtemp warning circuit, touch the end of the tan wire to the cylinder head with the key in the on position -- steady tone should sound from the buzzer located in the control box. Might want to take a closer look at your tan wire -- maybe the white one yellowed a bit. In '79 they changed that to yellow/red.

- Q: Replacing my 3 prong dryer outlet but there is a blk, red, wht, and a bare wire in the box. I know where the colored ones go on the outlet but what do I do with the bare one? I didn't remove the old one so I don't know how the old 3 prong outlet was wired with these wires. Thanks.

- Dryer Plug Wiring

Send your message to us

Loop Tie Wire/ Binding Wire Packing Bind Wire High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords