Geomembrane Materials:LDPE Geomembrane Liner for Landfill Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LDPE Geomembrane Introduction

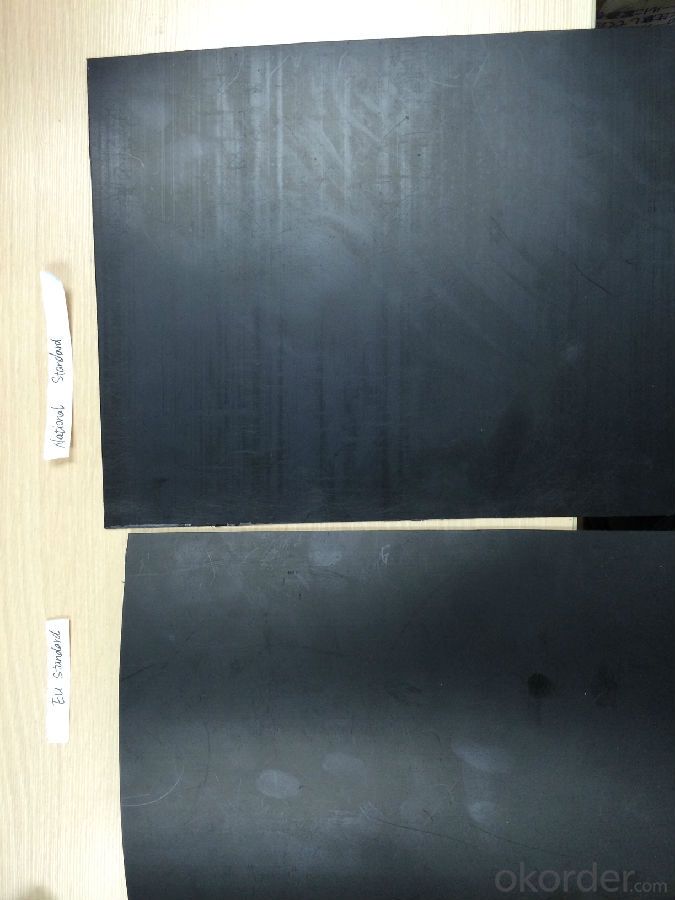

LDPE Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer. Its material is LDPE.

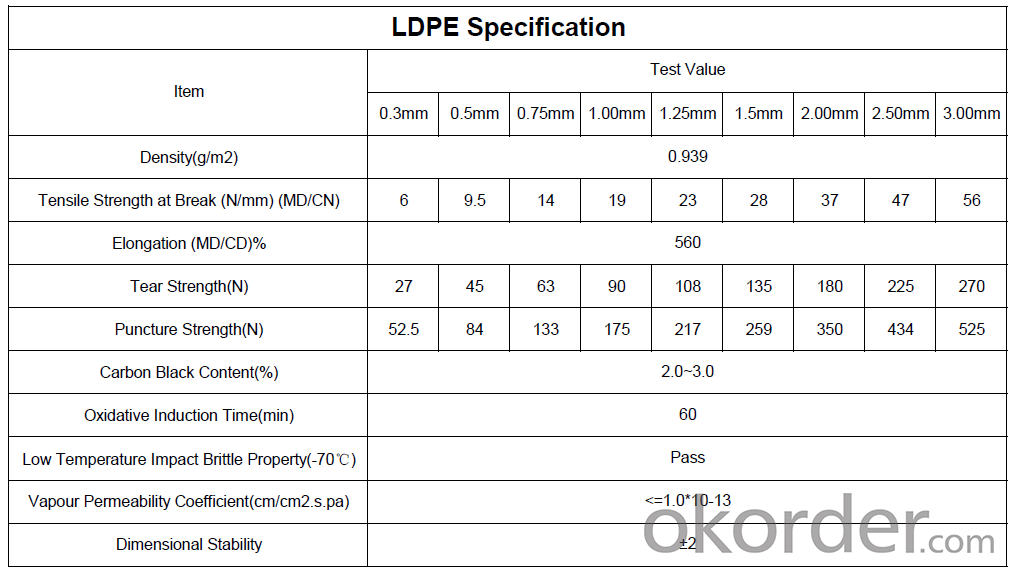

LDPE Geomembrane Specification

1)Material: LDPE

2)thickness:0.3mm~3.0mm

3)width:2m~7m

]] LDPE Geomembrane Package:

LDPE Geomembrane Package:

1. PE film inside, and Woven bag outside.

2. Packaged in container.

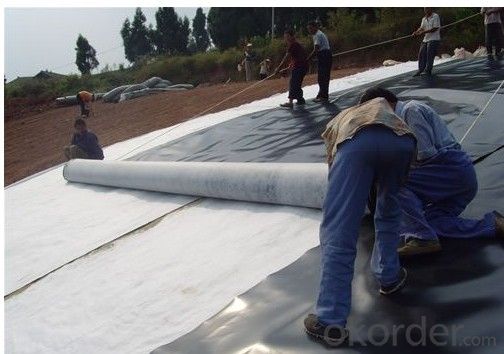

LDPE Geomembrane Application:

LDPE Geomembrane Application:

Landfill lining

Landfills capping

Water reservoirs

Pond-lining

Irrigation canals

Tunnels

Product Advantage

1.Some raw materials are produced by ourselves, or imported from overboard, so we could control the cost and quality to competitive in the market.

2. We have research team and laboratory, so we could research new products by ourselves and produce according client’s request.

3. There are more than fifty produce lines, so we could guarantee the delivery time.

4. We supply our products to many national projects in many countries, so our quality is stable and reliable.

5. If you have problem during your project when using our product, we could arrange our engineer to help.

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Can we get samples?

- A: Yes, we could arrange samples for free.

- Q: How do geomembranes contribute to energy production projects?

- Geomembranes contribute to energy production projects by providing a reliable and cost-effective solution for containing and managing liquids and waste materials. They are used in various applications, such as lining reservoirs, ponds, and landfills, to prevent leakage and seepage of fluids. This ensures the efficient storage and transportation of resources, such as water, oil, and gas, which are essential for energy production. Additionally, geomembranes help in the construction of sustainable energy infrastructure, such as solar farms and wind turbine foundations, by providing a protective barrier against soil erosion and groundwater contamination. Overall, geomembranes play a vital role in enhancing the safety, efficiency, and environmental sustainability of energy production projects.

- Q: What's the function of the base membrane of wall cloth?

- 1: Wall cloth base film is water-based with no strong taste. It is environment-friendly product in place of varnish. It can produce a hard protective film between the wallpaper and wall space, which can protect the wall space, and strengthen the water resistance of the wall bottom. It is mildew proof and antimicrobial. 2: The wall should be smooth and dry. 3: The concrete wall should be made level with putty powder. 4: For the wall space after scraped with talcum?powder is smooth, there is loose powder existent. The wallpaper should be pasted after sanding of the wall. 5: All walls in need of wallpaper pasting (concrete walls, gypsum walls, wooden fiberboard, blockboard, etc.) must first be scraped, and after they are completely dry, brush wallpaper base film on them once and until the film is dry, wallpaper pasting can be started. (If the base film is not sticky to your hand, it indicates it is appropriate to put up wallpaper at this time.)

- Q: What is the method of sticking membrane on cabinet?

- First, clean cabinet surface. It is recommended to use medical alcohol with 75% concentration, which is easy to clean and dry. Measure the length, width and height to stick with tape, then cut on the purchased membrane. To avoid waste, you'd better draw on draft paper. Finally, stick from top-down, and stick right bit by bit, or it would be difficult to handle if you find slanting in the end.

- Q: Can plastic wrap be steamed?

- No, the plastic wrap can't be steamed for it is a kind of plastic package product. It usually uses ethylene as master batch and is made by polymerization reaction. The plastic wrap is mainly used for food heating in microwave, refrigerator food preservation, and fresh food and cooked food packaging. It is also widely used in the field of food packaging in family life, supermarket stores, hotels, restaurants and industrial production. Plastic wrap can be classified into many types according to the material it uses and the added plasticizer, and it can be applied to different occasions. Plastic wrap is favored by people for its convenience, economy and beauty. However, plastic wrap generally contains added plasticizers in the production process, and thus its impact on human health has also been a concern.

- Q: the using method of Film thickness gauge ?

- This instrument is widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields. it is the necessary equipment for the material protection. Magnetic measuring mechanism method, when the probe is in contact with the cladding, the probe and the magnetic metal substrates constituting a closed magnetic circuit, due to the presence of a non-magnetic coating, the magnetic resistance changes, by measuring the amount of change we can obtain the thickness of the coating.

- Q: Can geomembrane be used in building a methane tank?

- Nobody will adopt this stupid method. You can ask a qualified worker for help If you do not know how to do it.

- Q: What materials are used in the upper layer of the protective layer of geomembrane? ? Why don't you use clay?

- Compare to geotechnical cloth, clay has poor performance, so we use geotechnical cloth more as upper reaches of the protective layer.

- Q: What are the differences between PE geomembrane and PVC geomembrane?

- The difference is that the raw materials to produce geomembrane are different, and the flexibility is also different.

- Q: What is the role of geomembranes in environmental remediation projects?

- Geomembranes play a crucial role in environmental remediation projects by acting as a barrier between contaminated soils or water bodies and the surrounding environment. They are used to prevent the spread of pollutants, such as chemicals or hazardous waste, by containing and isolating them within specific areas. Additionally, geomembranes can be used to control the flow of groundwater, protect underlying soils from erosion, and create containment systems for landfills or waste storage facilities. Overall, geomembranes are essential in ensuring the success and effectiveness of environmental remediation efforts.

- Q: What are the features of film mulching door sheet?

- More eco-friendly, natural color, anti - dirty, anti -light, easy to clean, non-discolouring, various design?and?colours.

Send your message to us

Geomembrane Materials:LDPE Geomembrane Liner for Landfill Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords