Lightgage Steel Joist For Ceiling System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Newest metal cd&ud profile roll mill machine

Lightgage steel joist

1.Hot dip galvanized steel, Q195, Q235

2.Usage: internal construction ceiling suspended

3. 60*27, 27*28

Lightgage steel joist for ceiling system

1.Material:hot dip galvanized steel

2.Surface treatment: roll coated

3.Application: ceiling grid system

4.Zinc content: 60-140g per sq.m.

1. light weight, high intension, waterproof, earthquake-resistance, dustproof, sound isolation, sound absorption, constant temperature,etc.

2. short time construction peiod and convenient and simple construction.

Usage:

1.used for the plant, high-rise building construction

2.used for the bridge, shipment building

3.used for lifting and transportation machinery, equipment manufacturing base building

4.used for the support, foundation pile manufacturing

5. Payment terms: 30% tt in advance, the balance against the LC or the copy of BL.

6. Package: in bulk or in bundle.

3.Image

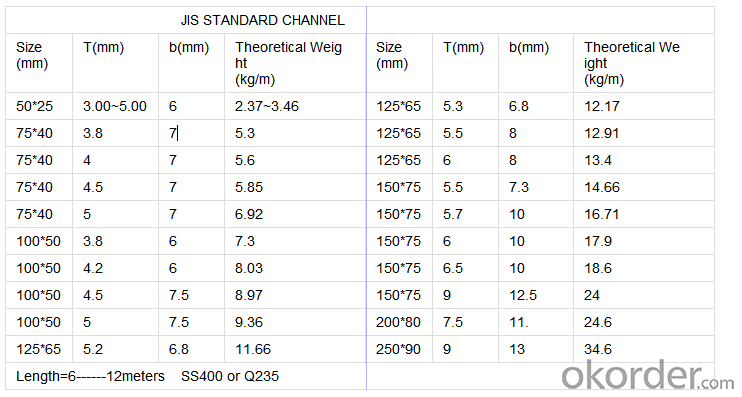

4.Detailed Specification

5.FAQ

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

- Q: Light steel keel to do a layer of gypsum board layer of nine layers of the wall how much money a square, the price is simple or double-sided?

- Sure to press the double calculation, not to mention fixed nine plywood than gypsum board but also a little trouble. The specific price per square is not good to say, there are differences in the price of different regions. I received a company two months ago, a small project, to my wall cost of labor, single and double back, 30 a square. Local minimum wall monolithic gypsum board partition 15 yuan per square, high in 20 or so. A layer of nine percent a layer of gypsum board, the minimum also 30 a square.

- Q: Light steel keel cut off the keel and the ground with what fixed?

- Playing a good line, with 25 steel nails directly to the keel to the ground fixed, If the ground is too hard nails do not enter, use hammer to play the cork now, and then in the fixed keel.

- Q: Who used the light steel keel gypsum board to do the wall?

- Or do not use the light steel keel effect is not good or better brick I think a lot of places in the decoration are permanent investment so we must consider good for a moment of trouble or save money on the simple get

- Q: Shanghai light steel keel ceiling, wall quotes

- Depends on the use of good and bad materials. Ordinary ceiling also 30-40, partition 35-45, I was doing this is what the project. Can contact me. Offer

- Q: Light steel keel wall in the end is how much money to know

- The partition depends on whether you are single or double-sided single-sided 30 a square double-sided 50 a square called 70 are cut your gypsum board has 13 to 23 blocks have you do partition And not good gypsum board as long as 14 to 15 pieces of gypsum board on it

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- After the installation of the gypsum board, the paper gypsum board installation and the ground to stay in the gap, so as not to drag the ground to do when the tide back. If you consider the sound effects can be filled with sound-absorbing cotton, but the effect is not good. Really too loud, you can use cotton plug The

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Do of course But I suggest do not do it! You do not want to move the floor, you put the floor cut off the partition of the piece. Directly to the disadvantages: 1: wooden floor flexible, partition instability. 2: you are not bad when the wall and the floor shut. 3: sound insulation is certainly worse

- Q: Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- Can ah, the paper gypsum board above also scraping putty ah, the workers will deal with, you just ask the request on it, professional things professional do

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- If the middle of the empty iron angle, it is estimated that the master will be in the corner iron welding rods down to install! Some of the master will use wire hanging, but many people do not use the iron wire rod. Then install baking paint or paint keel, Put the mineral wool board up just fine!

- Q: Curved gypsum board wall technology.

- The curvature of the gypsum board can not be bent directly into the required curvature; if slightly larger, you can spray a small amount of water or water bend into; and then a large curvature of the keel to be encrypted, with plaster slab splicing, and then putty leveling on the line.

Send your message to us

Lightgage Steel Joist For Ceiling System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords