Lightgage Steel Keel Ceiling Profile for Steel House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

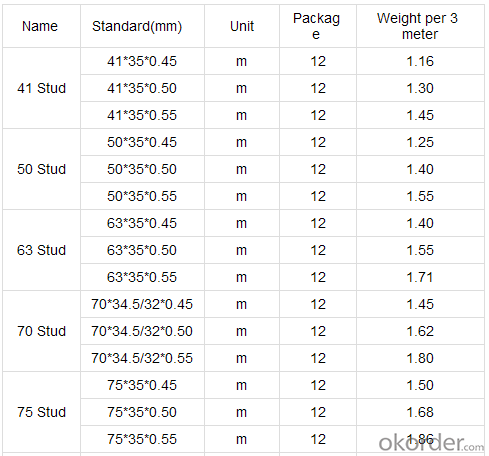

Specifications

1. Hot dip Galvanized

3. Grade: Q235, Q 345

4. Thickness:1.5 mm - 3.5mm

5. H: 100-350 B: 40-120.

China supplier buying gypsum drywall partition metal track

Material:hot dip galvanized steel

Surface treatment: roll coated

Application: ceiling grid system

Zinc content: 60-140g per sq.m

Factory sale price.OEM

Samples for free

Rustproof

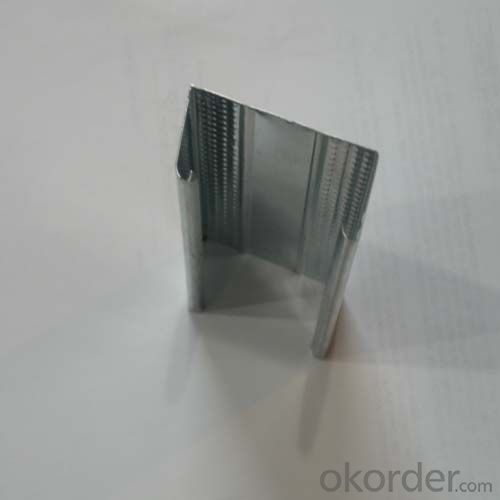

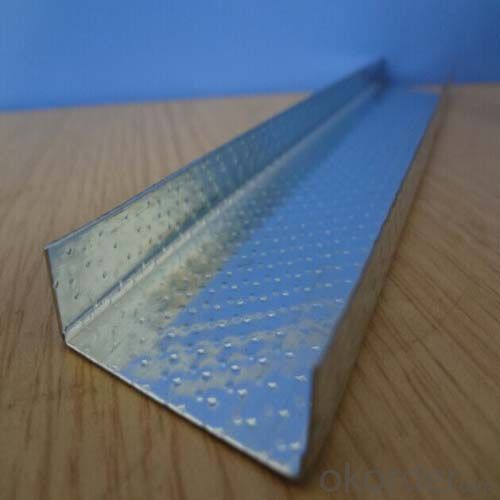

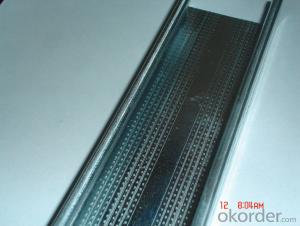

3.Image

4.Detailed Specification

5.FAQ

A.Plasterboard Introduction:

Plasterbord is also called gypsum board or drywall. It differs from other panel-type building

products, such as plywood, hardboard, and fiberboard, because of its noncombustible core

and paper facers.

When joints and fastener heads are covered with a joint compound system,plasterboard

creates a continuous surface suitable for most types of interior decoration.

1.Environmental friendly

2.Non-combustible

3.Strong nail holding power

4.Heat & sound insulation

5.Smoothness ceiling board

6.Light weight in unit acreage

7.Square Edge or Tapered edge ceiling board

B.Application of Plasterboard

1. Residential-Flats, Bungalows, Villas, Farm houses.

2. Commercial- Small work places to corporate offices.

3. Hospitality- Clubs, Discs, Hotels, Restaurants, All types of functional places.

4. Healthcare- Clinics, Hospitals, Polyclinics.

5. Institutional- Schools, Colleges.

6. Entertainment- Auditoriums, Performance theaters, Studios.

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- That depends on whether you are hanging flat or modeling top friends. See you want to hang double gypsum board, then I will tell you according to the price of flat top, package package material monolithic gypsum board ceiling 80 yuan / square or so, the wages of each place is different, plus a layer of plaster Board 20 dollars / square to the top, because a gypsum board is 2.88 square feet, the price is twenty or thirty dollars, the other to send you a little advice: ceiling with a screw must use 8-10mm, can not use 6mm

- Q: Consultation: What is the keel of the living room ceiling?

- Light steel keel, it is not on the use of wood side

- Q: There are several specifications for light steel keel with household ceiling

- Light steel keel according to the use of hanging keel and cut keel, Product specifications series of keel main specifications are divided into Q50, Q75 and Q100. The main specifications of the ceiling keel are divided into D38, D45, D50 and D60.

- Q: Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated ceiling is a combination of decorative and practical multi-function ceiling. Ceiling keel, integrated ceiling accessories, is a play on the role of supporting the entire ceiling plate accessories. In general, the ceiling keel is divided into light steel keel, wood keel, aluminum keel and so on. Distinguish between the ceiling with a wooden keel good or light steel keel good

- Q: Light steel keel gypsum board ceiling lamp how to install

- This is not the most basic process? Cutter to open the downlight to buy the LED is the external spotlight effect is kind ~

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling in the wood keel spacing: 1, light steel keel: keel for the edge of the dragon, the lamp slot position with keel or woodworking board production, there are wood production office to brush fire paint, keel at least 50, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, gypsum Between the board and the board to be reserved for 5-8 mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to be smooth and solid, shaped to be smooth lines; 2, keel: keel at least 3 × 4 or more, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, hanging bar is strictly prohibited direct use of wood wedge nail to the top, brush tight fire paint until the keel color can not see the dragon A layer of full-legged rice eucalyptus core after nine on the gypsum board, gypsum board and the board between the people to set aside 5-8mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to do To the formation of solid, shaped to do smooth lines; 3, aluminum buckle board: strict requirements level, light steel keel bayonet to be aligned, keel spacing of 50 or less, hanging spacing 60-80 cm is appropriate, the board when the hand to light, so as not to press the board, And the contact with the tile is not tight to use the sealant to play tight; 4, aluminum-plastic plate: keel at least 3 × 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80cm is appropriate, brush tight fire paint, keel on a layer of full-legged rice eucalyptus core 9% Adhesive paste aluminum-plastic plate, aluminum-plastic plate between the board to be reserved for 3-4mm gap, prepared to fill other colors play the effect of sub-grid, to be smooth and solid, shaped to do smooth lines, folding The angle can not be broken.

- Q: Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- 1, gypsum board ceiling does not require the floor, which is fixed on the light steel keel above. In order to prevent the board due to deformation cracking, there are ceiling to do double gypsum board ceiling. 2, if the ceiling has a shape, can be made of wood-based board to shape the profile of tires, and then seal the gypsum board to do latex paint. 3, in the wood grass-roots board on the batch of putty put the latex paint is not good, will crack, because the moisture absorption of wood products, it is recommended to seal the gypsum board cover again to do latex paint.

- Q: Light steel keel ceiling installation detailed process

- Simpler. Expand the screw to fit and connect the hanging bars. 2, arranged the main keel, 3, deputy keel. Finish

- Q: Light steel keel how to do secondary ceiling

- From top to bottom to do, the highest point to do a good job, and then do the following level, and the wood is interspersed with the construction is good, if not let it only play two rows of hanging bars

- Q: Home decoration living room ceiling (light steel keel or wood keel) between the two, what is the difference?

- Light steel keel ceiling, from the small area of the process is harder than the wood keel, but the high flatness

Send your message to us

Lightgage Steel Keel Ceiling Profile for Steel House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords