Biaxial Geogrids Suppliers Oklahoma USA - Lightweight Fiberglass Polypropylene High Strength Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

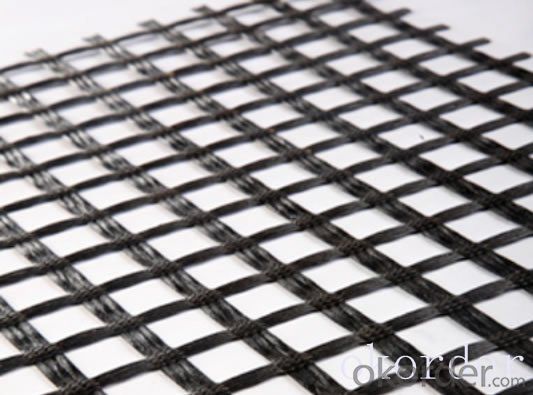

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements).

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

EGA50-50, EGA80-80, EGA100-100

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Which floor is paved on the roadbed

- Fixed grid end, by laying machine or manual will grill slowly pulled forward each shop, shop 10 meters long artificial investigation at a time, until a volume grating puwan, put the next volume, operation with; 3, ground shop: Volume long unit as the laying of the long, should be covered grille with long period, then the overall check again laying quality, then laying the next paragraph, a laying, grille grille to overlap a grid spacing for the lap length, tie fixed line continues to spread second section direction.

- Q: How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first preparing the ground surface and ensuring it is compacted and leveled. The geogrid is then laid out on the prepared surface and secured in place using stakes or anchor systems. It is important to ensure that the geogrid is properly tensioned and aligned to provide maximum stability and reinforcement. Finally, the geogrid is covered with additional layers of soil or other construction materials to complete the installation.

- Q: Are geogrids suitable for use in soil reinforcement for wind turbine foundations?

- Yes, geogrids are suitable for use in soil reinforcement for wind turbine foundations. Geogrids provide effective reinforcement by increasing soil stability, reducing settlement, and improving load distribution. They enhance the overall performance and longevity of wind turbine foundations, making them a suitable choice for such applications.

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

- Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention, protection, light weight, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance. Common non-woven fabric, consider the use of water inside the polyethylene polypropylene fiber waterproof is also used

- Q: What is the lowest price of two-way plastic geogrid?

- You need to look at how much the kn

- Q: I would like to ask the geotechnical engineering of highway engineering, geogrid raw materials for the conventional test items, parameters?

- The mechanical properties (including Strip Tensile test, joint / joint width tensile test, solder stick limit peel strength test); sampling frequency: each batch of incoming inspection time, quantity of each test group representing more than 500 volumes

- Q: How do geogrids help in reducing the risk of landslides?

- Geogrids help in reducing the risk of landslides by providing reinforcement and stability to the soil. They are typically installed in layers within the ground to improve its strength and prevent movement. Geogrids act as a barrier, distributing the forces exerted by the soil and reducing the likelihood of slope failure. They increase soil cohesion and friction, enhancing the overall stability and preventing landslides from occurring or minimizing their impact.

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing additional strength and stability. They act as a reinforcement material, distributing the forces and loads evenly throughout the structure. This helps to prevent soil erosion, slope failure, and settlement, ultimately enhancing the overall durability and longevity of the structure.

- Q: Can geogrids be used in reinforcement of retaining walls?

- Yes, geogrids can be used in the reinforcement of retaining walls. Geogrids are commonly used in retaining wall construction to enhance the stability and strength of the structure. They are typically placed within the soil layers of the wall to distribute the lateral forces and increase the overall resistance to soil movement. This reinforcement technique helps to prevent the wall from overturning or sliding, ensuring its long-term stability.

- Q: Can geogrids be used in reinforced earth bridge abutments?

- Yes, geogrids can be used in reinforced earth bridge abutments. Geogrids are commonly used in reinforced earth structures as they provide soil reinforcement and improve the stability and strength of the structure. In the case of bridge abutments, geogrids can be used to reinforce the soil backfill behind the abutment walls, enhancing its load-bearing capacity and reducing the potential for settlement or failure.

Send your message to us

Biaxial Geogrids Suppliers Oklahoma USA - Lightweight Fiberglass Polypropylene High Strength Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords