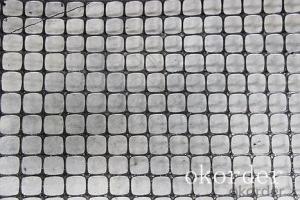

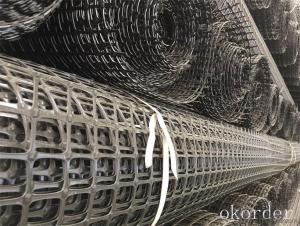

Light Weight PP Plastic Polypropylene Geogrid Biaxial Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Plastic polypropylene geogrid biaxial

The properties of Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geogrids prevent soil erosion?

- Geogrids prevent soil erosion by providing stability and reinforcement to the soil. They are typically made of high-strength materials, such as polyester or polypropylene, and are installed within the soil to distribute and transfer loads. This helps to increase the soil's resistance to erosion caused by factors like water flow or slope instability. The geogrids act as a barrier that holds the soil particles together, preventing them from being washed away or displaced.

- Q: The difference between composite geomembrane and bentonite waterproof blanket

- Different waterproof performance. Composite geomembrane: composite geomembrane composite impermeable membrane is divided into one cloth and two membrane. Tensile, tearing resistance, bursting and other physical and mechanical properties of high index, the product has high strength, good elongation, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good performance of seepage control, etc..

- Q: How much is the tensile strength of Geogrid

- Warp knitting: 15KN--200KN, the highest foreign to 400KN.

- Q: Can geogrids be used in streambank stabilization applications?

- Yes, geogrids can be used in streambank stabilization applications. Geogrids provide reinforcement and stability to the soil, preventing erosion and maintaining the integrity of streambanks. They help to distribute the load and resist the forces of water flow, making them an effective solution for streambank stabilization.

- Q: What is the overlap length of the two-way geogrid? What is the overlap length of geotextiles?

- Steel nail. Geotextile lap length is 50cm to 1m

- Q: Can geogrids be used in mining and landfill applications?

- Yes, geogrids can be used in both mining and landfill applications. Geogrids are commonly used in these industries to reinforce and stabilize the soil or waste materials, preventing erosion, improving stability, and enhancing the overall performance of the structures.

- Q: In the case of the subgrade with Geogrid

- Geogrid is suitable for various kinds of dams and subgrade reinforcement, slope and tunnel wall reinforcement. Large airport, parking lot, wharf freight yard and other permanent bearing foundation reinforcement. The geogrid is used to increase the bearing capacity of the road (ground) foundation, and the service life of the Yan Changlu foundation. The geogrid is used to prevent the collapse of the road (ground) surface or crack, and keep the ground beautiful and tidy. The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost. Geogrid is used to prevent cracks in culvert. Geogrid is used to enhance soil slope and prevent soil erosion. The geogrid is used to reduce the cushion thickness and save the cost. Geogrid for stability of slope greening environment support grass mat. The geogrid can effectively isolate the seismic force transfer, and plays an important role in enhancing the seismic stiffness, strength and stability of the embankment. The successful application of geogrid is expected to reduce the common embankment diseases in high intensity seismic region, and improve the seismic capacity of the road. However, the current seismic design codes for highway and railway are not corresponding to the seismic performance of geogrid reinforced embankment.

- Q: What are the models and specifications of Geogrid for road

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: Can geogrids be used in subgrade stabilization?

- Yes, geogrids can be used in subgrade stabilization. Geogrids are commonly employed in civil engineering projects to enhance the stability of subgrade soils. They provide reinforcement and distribute loads, reducing the potential for soil movement and settlement. Geogrids are effective in improving the strength and load-bearing capacity of subgrade soils, making them suitable for subgrade stabilization applications.

- Q: What are the different types of geogrids?

- There are several different types of geogrids, including biaxial geogrids, uniaxial geogrids, and triaxial geogrids. Biaxial geogrids have strength in two directions and are commonly used for soil stabilization and reinforcement. Uniaxial geogrids have strength in one direction and are often used for retaining walls and steep slopes. Triaxial geogrids have strength in three directions and are primarily used for load-bearing applications such as road construction and pavement reinforcement.

Send your message to us

Light Weight PP Plastic Polypropylene Geogrid Biaxial Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords