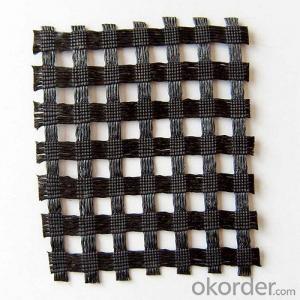

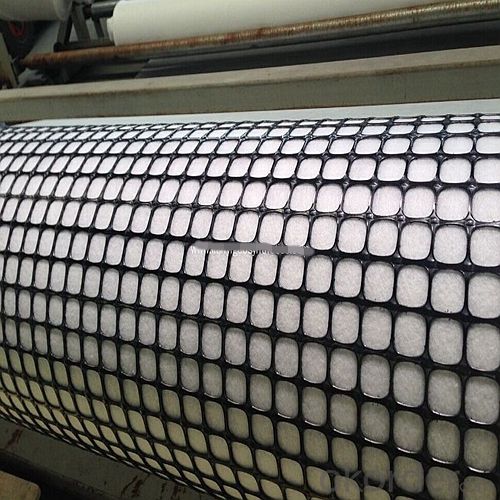

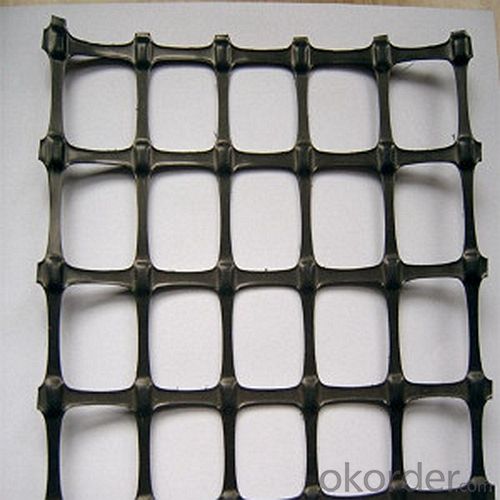

Lightweight Fiberglass Polypropylene Geogrid Geotextile Fabric for Leach Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

Briture

Model Number:

Biaxial

Material:

Fiberglass

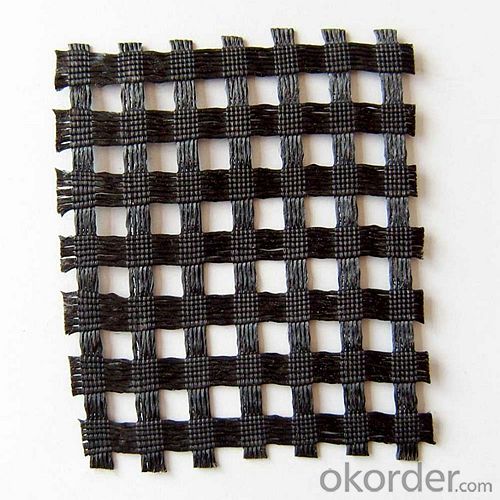

Tensile strength:

100kn

Roll Width:

3.95m

Roll length:

100 Meter

Porducts Description

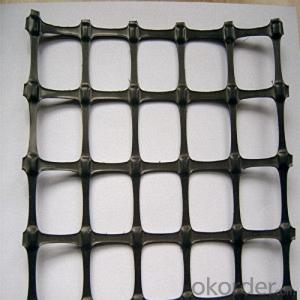

Production function

1.It can be applied in all kinds of roads,airports to enhance the roadbed;

2.It can be applied in a large car park and terminal freight yard,etc. to strengthen the foundations of a permanent load;

3.It can be applied in rail, road slope's protection;

4.It can be applied to enhance the culvert;

5.It can be applied as a secondary enhancement after the uniaxial Geogrid soil enhancement, further enhance the soil;

6.It can be applied in mining, tunnel reinforcement.

7.Network used for animal and husbandry;

8.Network used for cage fishing.

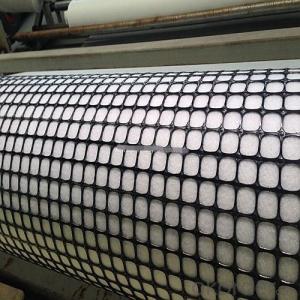

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles improve the performance of geofabrics?

- Geotextiles improve the performance of geofabrics by providing added strength, stability, and filtration capabilities. They act as a separator, preventing the mixing of different soil layers while allowing water to pass through. Geotextiles also reinforce the geofabrics, enhancing their load-bearing capacity and preventing soil erosion. Overall, geotextiles enhance the durability and effectiveness of geofabrics in various civil engineering and environmental applications.

- Q: Geotextile CBR tear strength rate is how much

- Geotextile CBR bursting strength is generally in accordance with the national standard GB / T-2017 "geosynthetics static top breaking test (CBR method)" according to the national standard GB / T-2017 standard requirements of geotextile CBR strong pre-tension 20N. According to the national standard GB / T-2017 standard requirements of geotextile CBR strong rate of (50 ± 5) mm / min.

- Q: Is there a geotextile for reed cultivation?

- Big slope pond words use better, need depth laying, with geomembrane

- Q: Can geotextiles be used for reinforcement of railway tracks?

- Yes, geotextiles can be used for reinforcement of railway tracks. Geotextiles can provide stability and prevent the deformation of railway tracks by distributing loads and reducing stress on the subgrade. They can also improve drainage and prevent the intrusion of fine particles, enhancing the overall performance and lifespan of railway tracks.

- Q: What is the geotextile customs code?

- Hello: I can only give an example: if you ask the goods belong to the weight per square meter of more than 150 grams of non-woven weaving, can be returned, because you do not have a detailed description of the source of raw materials, production processes, Into the product code under 5603.1410. If you are satisfied with my answer, I would like to be accepted and given praise, thank you!

- Q: Polypropylene geotextile and polyester geotextile with the naked eye how to distinguish

- Polypropylene compared to white, polypropylene fiber than polyester fiber density point, anti-aging anti-aging of polypropylene, polyester aging,

- Q: What is PAG in PAG composite geotextile

- Should be a high-strength glass fiber or grille and non-woven woven or bonded together geotextile, PAG is estimated that the product is a product code, one may be nominal vertical and horizontal strong, similar geogrid Such as PAG50-160, the other may be used cloth and grille specifications, such as 50kn grille and 160 grams of nonwovens

- Q: How do geotextiles aid in the reduction of differential settlement?

- Geotextiles aid in the reduction of differential settlement by providing a stable and uniform foundation for the soil. They distribute and equalize the load across the soil, preventing differential settlement and ensuring the overall stability of the structure. Additionally, geotextiles can help in reinforcing weak soils, improving their bearing capacity and reducing the potential for differential settlement.

- Q: What are the factors that affect the strength of geotextiles?

- The strength of geotextiles can be affected by several factors such as the type and quality of materials used, the manufacturing process, the weight and thickness of the geotextile, the presence of any coatings or treatments, and the installation and environmental conditions in which the geotextile is used.

- Q: Does geotextile affect water purification?

- Do not know what you use after the purification of water, if not drinking water, I think it will not affect the water quality, the general purpose of water purification, geotextile will not affect, because the geotextile material is polyester or polypropylene, In the chemical nature of relatively stable, no changes in room temperature conditions, so there will not be any impact on water quality

Send your message to us

Lightweight Fiberglass Polypropylene Geogrid Geotextile Fabric for Leach Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords