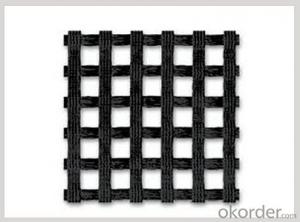

Geotextiles and Geomembranes - Lightweight Fiberglass Polypropylene Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

PET geogrid

15X15,20X20,25X25,30X30,35X35,40X40,50X50,60X60.

70X70,80X80,90X90,100X100,110X110KN

steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KNRoad bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different installation methods for geotextiles?

- There are several installation methods for geotextiles depending on the specific application and project requirements. Some common methods include loose-laid, anchored, and mechanically stabilized installation. In the loose-laid method, the geotextile is simply placed on the ground surface without any additional fixation. Anchored installation involves securing the geotextile to the ground using stakes, pins, or other fasteners. Mechanically stabilized installation utilizes heavy machinery or equipment to mechanically compact the geotextile into the ground. The choice of installation method depends on factors such as soil conditions, project specifications, and desired performance outcomes.

- Q: What is the purpose of using geotextiles?

- The purpose of using geotextiles is to provide a wide range of functions in different construction and engineering applications. These functions include soil stabilization, erosion control, filtration, drainage, separation, and reinforcement. Geotextiles act as a protective barrier, improving the performance and lifespan of infrastructure projects such as roads, embankments, retaining walls, and landfills.

- Q: How much is the price of anti-geotextile?

- In the actual engineering procurement, generally between the two geotextiles need about> 250px lap, so the procurement is usually based on the actual area plus 15% to 20% loss. Hongxiang new material Li Qian geotextile price is also required according to the specific needs of the project to specify the model, the specific offer.

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing reinforcement, filtration, and erosion control. They act as a barrier between the soil and water, preventing soil erosion and promoting stability. Geotextiles also help in filtering out any fine particles or contaminants, ensuring clean and clear water. Additionally, they enhance the strength and durability of the pond or lake structure, increasing its longevity and resistance to wear and tear.

- Q: What are the key considerations for geotextile installation in high temperature environments?

- Some key considerations for geotextile installation in high temperature environments include selecting a geotextile material that can withstand high temperatures without degrading or losing its property, ensuring proper storage of the geotextile rolls to prevent heat damage before installation, using appropriate installation techniques to minimize the exposure of the geotextile to direct sunlight or extreme heat, and conducting regular inspections and maintenance to monitor the performance of the geotextile in the high temperature environment.

- Q: Can geotextiles be used in coastal protection?

- Yes, geotextiles can be used in coastal protection. Geotextiles, which are permeable fabrics made of synthetic fibers, can be utilized for erosion control, shoreline stabilization, and sediment filtration in coastal areas. They can help prevent soil erosion and provide stability to slopes and embankments. Additionally, geotextiles can be used in the construction of groynes, breakwaters, and revetments, providing protection against wave action and reducing the impact of coastal erosion.

- Q: Can geotextiles be used in green wall construction?

- Yes, geotextiles can be used in green wall construction. Geotextiles provide several benefits such as soil containment, erosion control, and moisture retention, which are essential for the successful establishment and growth of plants in green walls. They can help improve the structural integrity of the wall, prevent soil erosion, and provide a suitable environment for plant roots to grow and thrive.

- Q: What are the key factors affecting the clogging behavior of geotextiles?

- The key factors affecting the clogging behavior of geotextiles include the size and type of particles in the surrounding soil, the hydraulic gradient, the flow rate and duration of water passing through the geotextile, and the quality and depth of the geotextile itself.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: Ask geotextile factory in the use of geotextile aperture detector detection method which?

- Hello, geotextile detection method in GB / T and GB / T geotextile aperture in the introduction, you can look at these two standards. The first is geotextile pore size detection wet sieve method, the second is geotextile aperture detection dry sieve method. As the name suggests the first of these two methods is the participation of water, the other is basically the same, are placed in a single layer of geotextile standard small particles, through the vibration to detect the size of the leakage of particles to determine the geotextile pore size size. The difference is that the first standard in the need for continuous water on the particles, so the calculation method are also different. Specific detailed distinctions You can search these two criteria separately.

Send your message to us

Geotextiles and Geomembranes - Lightweight Fiberglass Polypropylene Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords