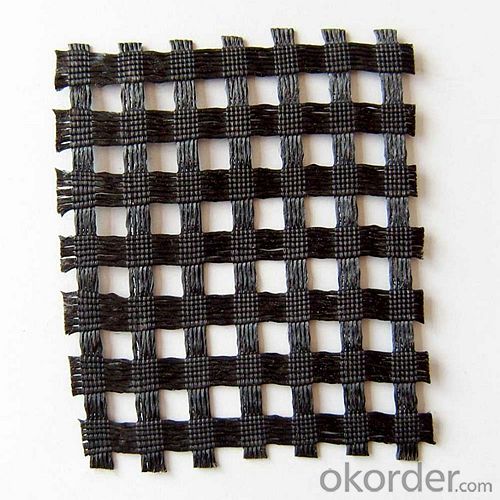

Light Weight Biaxial Polypropylene Geogrid Geotextile Fabric Roll Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

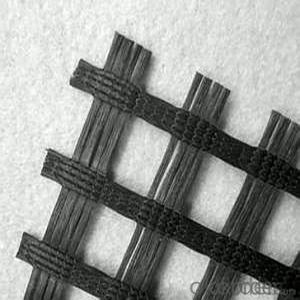

Product Introduction

Geogrid protects channel slopes, provides resistance and stability, protecting this object from erosion. Additional advantage is drainage along channels. Geogrid application considerably reduces losses, connected with fall of ground, landslides and deformation of slopes. In case of water streams construction, geogrid application allows planting trees and shrubs along the banks protecting them from ablation. Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Geogrid application is a way of soil reinforcement, On soil surface a plate is created according to the thickness of a corresponding geogrid: 50 mm, 100 mm, 150 mm, 200 mm (this standard range of products is manufactured by “Technostroytex” LLC).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What type of geotextile is used for soccer field

- Strong water seepage.

- Q: Can geotextiles be used in geosynthetic reinforced walls?

- Yes, geotextiles can be used in geosynthetic reinforced walls. Geotextiles are commonly used as a separation layer between different soil types in reinforced walls to prevent soil mixing and promote proper drainage. Additionally, they can provide additional tensile strength and stability to the wall structure.

- Q: How are geotextiles used in road construction?

- Geotextiles are used in road construction to enhance the structural integrity and lifespan of the road. They are placed between the subgrade and the base course to prevent soil erosion, improve drainage, and provide separation and filtration. Geotextiles also help to distribute loads and reduce cracking and rutting in the road surface.

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, and drain soil in a drainage system. They help prevent the clogging of pipes and provide additional stability and longevity to the overall system.

- Q: Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Q: Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are commonly used as liners, covers, and drainage materials in landfills to prevent soil erosion, control water flow, and improve stability and performance of the landfill structure.

- Q: Geotextile and non-woven fabrics What is the difference

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q: GB waterproof geotextile what price

- GB waterproof geotextile details please see

- Q: Are geotextiles suitable for use in geocell retaining walls?

- Yes, geotextiles are suitable for use in geocell retaining walls. Geotextiles are often used as a separation and filtration layer in geocell systems, helping to prevent soil erosion, improve drainage, and enhance overall stability of the retaining wall.

- Q: Can geotextiles be used for erosion control in river channels?

- Yes, geotextiles can be used for erosion control in river channels. Geotextiles are permeable fabrics that are designed to stabilize soil and prevent erosion by providing structural support and enhancing filtration. They can be installed in river channels to control erosion by reinforcing the riverbanks, protecting against scouring, and promoting vegetation growth. Geotextiles can effectively reduce sediment transport and maintain the stability of river channels, making them a suitable option for erosion control in these environments.

Send your message to us

Light Weight Biaxial Polypropylene Geogrid Geotextile Fabric Roll Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords