Atarfil Europe Self-Adhesive Geomembranes for Wall Thermal and Moisture Protection

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

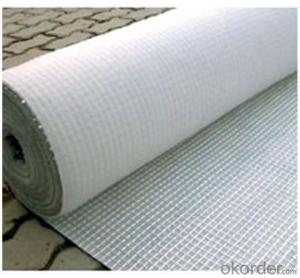

Self-Adhesive Geomembrane for Wall Thermal andMoisture Protection

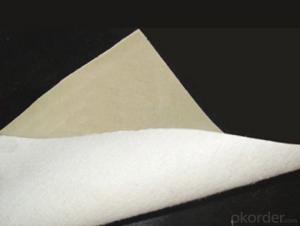

High performance self-adhesive geomembrane made from self-adhesive rubberbitumen glue

Specification of Self-Adhesive Geomembrane for Wall Thermal and MoisturePrtection

Thickness: 1.2mm - 2. Omm, 2m - 4m in roll width, the length as client ' s request.

Property of Self-AdhesiveGeomembrane for Wall Thermal and Moisture Protection

I. High tear strength and stability

2. Excellent in self-adhesive, easy for checking

3. Good self-healing property

4. Easy for construction

5. Special wet lay-up technique could be continuing construction under wetconditions even

Rainy season

Application of Self-AdhesiveGeomembrane for Wall Thermal and Moisture Protection

Mainly used in industrial and civil cellar underground structure, square floor,roof garden etc.

- Q: How do geomembranes contribute to the prevention of soil erosion in slope stabilization?

- Geomembranes contribute to the prevention of soil erosion in slope stabilization by acting as a barrier between the soil and the external environment. They effectively reduce water infiltration into the soil, thereby minimizing the erosive forces caused by rainfall and surface runoff. Additionally, geomembranes help to improve the stability of slopes by providing reinforcement and reducing the potential for soil movement. Overall, their use in slope stabilization helps to mitigate the risk of soil erosion and maintain the integrity of the slope over time.

- Q: What is the diatomite craft?

- The purpose of diatomite beneficiation is to remove the impurities including mud, debris, iron and aluminum to realize enrichment of diatom. General method is gravity milling, divided into dry and wet types. Dry separation is to remove gangue with air separator or remove organics, volatile matter and water with rotating dryer, mainly used for high grade ore. While wet separation is to remove larger density gangue impurities with hydrocyclone, mainly used for low grade ore;

- Q: How to maintain the paint film of solid wood floor?

- The waxing is persistent at the usual time

- Q: Can geomembranes be used in wastewater effluent storage and treatment facilities?

- Yes, geomembranes can be used in wastewater effluent storage and treatment facilities. Geomembranes are impermeable liners that can effectively contain and prevent the leakage of wastewater, providing a reliable solution for storage and treatment facilities. They are resistant to chemical degradation and provide a robust barrier against contaminants, making them suitable for containing and treating wastewater effectively.

- Q: Are geomembranes resistant to UV degradation in different climates?

- Yes, geomembranes are generally resistant to UV degradation in different climates. However, the degree of resistance may vary depending on the specific type of geomembrane material used and the duration and intensity of UV exposure. It is important to consider the specific climate conditions and consult with experts to choose the most suitable geomembrane for each application.

- Q: How to remove the oil film in the fish tank?

- There are several ways to remove oil film. 1 For those who keep small-sized fishes, they can bought several black molly. This kind of fish like to look for food on the surface of the water and they will eat the this layer of oil film! 2 You can establish nitrification system and the oil film will disappear. However, this method takes longer time. 3 There is a stale fish oil film removal on the market. This device can also remove the oil film, but you need to spend money!!! 4 The most effective, simplest and most economical way is to use a 1.25 liter coke bottle! The first step: Cutting out a reversed isosceles triangle with the side length of 2cm at the four fifths part of the coke bottle. The second step: Sinking the bottle down in the water and letting the floating oil flow slowly to the bottle when the bottle sinks to the triangle. Draining the bottle whe it is nearly full and then going on with the method! The oil film on the fish tank can be removed in this way. If it is a small tank, you only should try the method once while you should it two to three if it is a bigger tank.

- Q: What is the difference between the matte screen stick membrane and common film

- The matte stick membrane is different from the common stick membrane. the most common packaging film on the market has matte film and high penetration membrane, the advantages and disadvantages of the two is relative and the arbitrary affixed both according to your own needs and you can choose the two film, matte film is mainly anti fingerprint, when playing games it will not leave fingerprints, the screen looks very clean, but the common film doesn't have anti-fingerprint function, but the definition and perspective is better than matte stick membrane.

- Q: What is national standard of geomembrane?

- Polyethylene geomembrane new national standard GB / T17643-2011. The new standard increases single rough geomembrane and double rough geomembrane and delete EVA geomembrane.

- Q: How do geomembranes help in preventing land subsidence?

- Geomembranes help prevent land subsidence by acting as a barrier between the ground and any potential sources of subsidence, such as underground water or gas. They provide a stable and impermeable layer that prevents the migration of these substances, thereby reducing the risk of land sinking or collapsing. Additionally, geomembranes can also be used in soil stabilization and reinforcement techniques to enhance the overall stability and strength of the land, further mitigating the chances of subsidence.

- Q: What are the applications of geomembranes?

- Geomembranes have a wide range of applications in various industries and environmental projects. They are commonly used as liners in landfills, preventing the leakage of contaminants into the soil and groundwater. Additionally, geomembranes are utilized in the construction of reservoirs and dams to ensure water containment. They are also employed in mining operations to contain and manage wastewater and hazardous materials. In agricultural practices, geomembranes are used for pond liners and irrigation canal liners. Furthermore, they find applications in civil engineering projects, such as tunnels, underground storage facilities, and wastewater treatment plants, to provide a barrier against seepage and corrosion.

Send your message to us

Atarfil Europe Self-Adhesive Geomembranes for Wall Thermal and Moisture Protection

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords