Géomembrane Bassin TPO Geomembrane for Road, Railway, Highway, Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

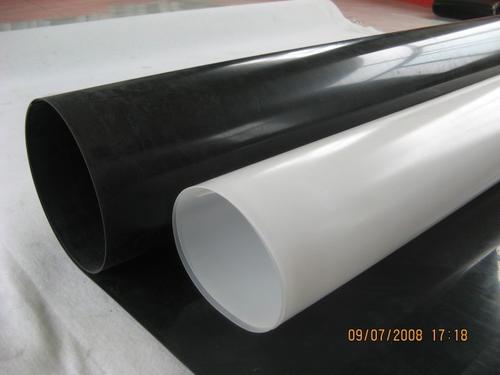

TPO Geomembrane for Road Railway Highway Tunnel

Made of polyolefin based on the Xavan® Product.

Specification of TPO Geomembrane for Road Railway Highway Tunnel

I. Thickness: 0.5mm

2.2m - 4m in roll width, the length as client ' s request

Property of Tpo Geomembrane for Road Railway Highway Tunnel

I. Light weight

2. Anti-aging, high strength and easy for construction

3. Good flexibility under temperature of -450C-950C

4. Excellent peel strength under low temperature

Application of TPO Geomembrane for Road Railway Highway Tunnel

I. Fish pond, stream, swimming pool

2. Aquiculture

3. Golf course, ski field, artificial la ke

4. Landfill, waste water treatment

5. Artificial wetland

6. Water conservancy project

7. M u nicipal p roject

8. Agricultu re (channel, irrigation la ke, methane to n k)

9. Reclaim land from the sea and Saline alkali soil improvement

- Q: How do geomembranes prevent biogas leaks in production facilities?

- Geomembranes prevent biogas leaks in production facilities by providing a durable and impermeable barrier that effectively contains the biogas. These specially designed membranes are made from high-quality materials that are resistant to degradation and have low permeability, ensuring that the biogas remains contained within the facility. Additionally, geomembranes are installed with proper sealing techniques and overlap joints to create a tight and secure enclosure, minimizing the risk of any leaks or gas escape. This prevents potential hazards, ensures safety, and maximizes the efficiency of biogas production facilities.

- Q: Why composite geo-membrane can not be used in underground garage?

- Composite geo-membrane was invented in China, applied in the The South-to-north Water Diversion Project with good anti-seepage effect. While there are no composite geo-membrane in foreign countries. It has also been widely used in subway?tunnel and other underground constructions. Of course, it can be used in underground garage , but you must choose the appropriate specifications. It is recommended to use 300g/1.0mm/300g composite geo-membrane. The following are the details. Composite geo membrane is geotechnical impermeable material made of plastic film as anti-seepage material and non-woven fabrics. Its waterproof performance mainly depends on the performance of plastic film. Impermeable plastic film at home and abroad are mainly polyvinyl chloride (PVC) and polyethylene (PE), which are Polymer chemistry flexible material with smaller proportion, good extensibility and high?adaptability?to the?deformation. Corrosion resistance, low temperature resistance, good anti-frost?property. The main mechanism is to block earth dam leakage passage by imperviousness of plastic film and bear hydraulic?pressure and adapt to deformation of dam with greater tensile strength and elongation. Non-woven geotextile is also a kind of macromolecule staple fibre chemical material shaped through acupuncturing or hot sticking, having high tensile strength and extensibility. Combined with plastic film, it can not only increases the tensile strength and anti-puncture ability of plastic film, but also increase the friction coefficient of contact surface and make the composite geo-membrane and packaging layer stable as the non-woven fabrics surface becomes rough. At the same time, they have good corrosion resistance to bacteria and chemical action, not afraid of acid, alkali, salt erosion, high seepage coefficient.

- Q: Geomembrane's features

- Width 6 meters wide composite film has high puncture-resistant strength and anti-friction coefficient, it can adapt to the ambient temperature range and has superior anti-drainage, it's applied in water?conservancy, chemical engineering, construction, transportation, iron, tunnels, waste disposal sites, etc.

- Q: is the graphite electrothermal?film useful?

- Generally speaking, the effect is good. One of its advantages is that the heating is fast, easy to control, and installation is not high. However, the heating effect and the degree of thermal insulation are related to the installation of electric heating film.

- Q: Can geomembranes be used in biogas plants?

- Yes, geomembranes can be used in biogas plants. They are often used as liners in anaerobic digesters and biogas storage tanks to prevent leakage and contamination of the surrounding environment. Geomembranes provide a durable and impermeable barrier that helps maintain the integrity and efficiency of the biogas production process.

- Q: What is the coated paper cups?

- first, you should understand what is called the coated paper cups coating a layer of HDPE on the surface of the paper is called the coated paper cups

- Q: How about the warm reflective film?

- Warm reflective film is very good. It is commonly known as "aluminum foil" or "tin foil". But strictly speaking, it is not real "aluminum foil" or "tin foil". In fact, it is a kind of product made of high vacuum aluminum?laminated?films, paper, cloth and other insulation materials. Warm reflective film is the key part of the floor heating system which ensures comfortable temperature of floor and improves the heat reflection and radiation.

- Q: Quality acceptance record sheets of waterproof concrete project insolation lot.

- 5.10.5 Quality acceptance record sheet of waterproof concrete insolation lot GB50208-2002 010501 □□ Unit (subunit) Project name No. 8 commercial and residential building, Guangming Garden, ×× City subsection(branch) Project name underground waterproof subsection project Acceptance site foundation1-19 / A-D Construction unit ×× city construction company Project manager ××× Executive standard and number of construction QB / T010501 waterproof project technique standards Stipulations of construction acceptance of construction quality specifications Inspection and assessment record of the construction unit Acceptance record of supervision(construction) unit Dominant item 1. the mix proportion and slump test value of raw materials Article 4.1.7 √ conformance to requirements 2. compressive strength, impermeability pressure Article 4.1.8 √ 3. detail practice section Article 4.1.9 √ General item 1. Surface quality Article 4.1.10 √ conformance to requirements√ 2. Crack opening ≤0.2 mm, and no holing √ 3. waterproof concrete structural thickness≥250 mm The protective layer of water face 50 mm ±15mm, -10mm ±10mm 8 9 7 6 6 6 6 8 8 6 6 6 4 4 4 5 3 2 6 Inspection and assessment results of construction unit Professional foreman (construction worker) ××× construction leader ××× conformance to requirements of acceptance specifications of construction quality. Professional quality inspector of projects: ××× × day × month 2003 Inspection results of supervision (construction) unit qualified acceptance Professional supervising engineer: ××× (professional technical leader of project in construction unit): × day × month 2003 5.10.5 quality acceptance record sheet waterproof concrete insolation lot

- Q: Can geomembranes be used for irrigation canals?

- Yes, geomembranes can be used for irrigation canals. They are often used as liners to prevent water seepage, ensuring efficient water delivery to crops and preventing soil erosion. Geomembranes offer a reliable and cost-effective solution for lining and protecting irrigation canals.

- Q: Can geomembranes be used in underground applications?

- Yes, geomembranes can be used in underground applications. They are often used in underground structures such as tunnels, landfills, and mining operations to prevent the leakage of liquids or gases. Geomembranes provide an impermeable barrier that helps protect the environment and enhance the durability and safety of underground projects.

Send your message to us

Géomembrane Bassin TPO Geomembrane for Road, Railway, Highway, Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords