PE Geomembrane LDPE/HDPE/EVA Geomembrane Liner for Landfills Capping

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

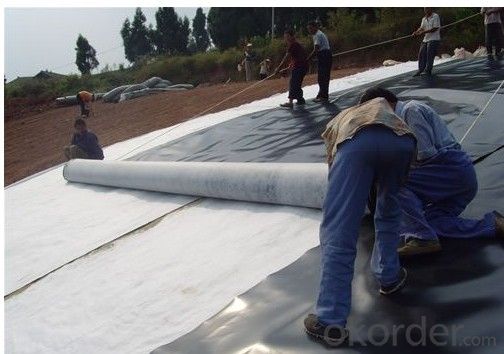

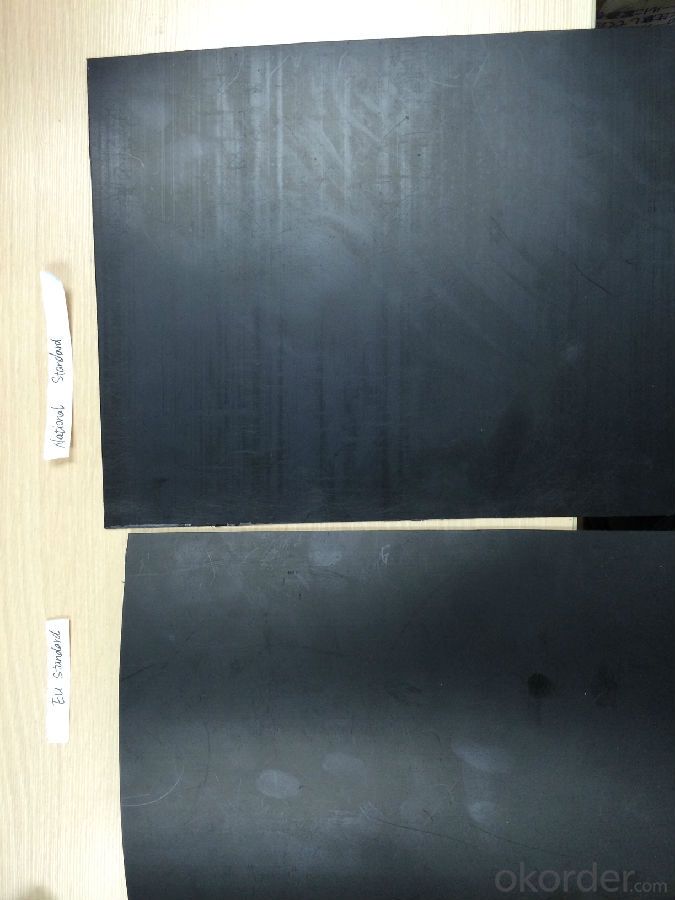

Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer. It is mainly divided into LDPE geomembrane, , HDPE geomembrane, EVA geomembrance and all kinds of composite geomembrane.

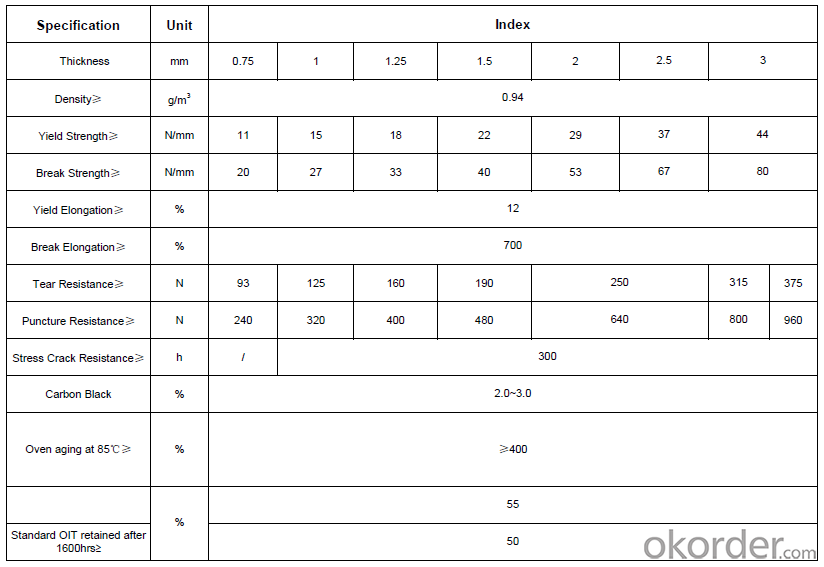

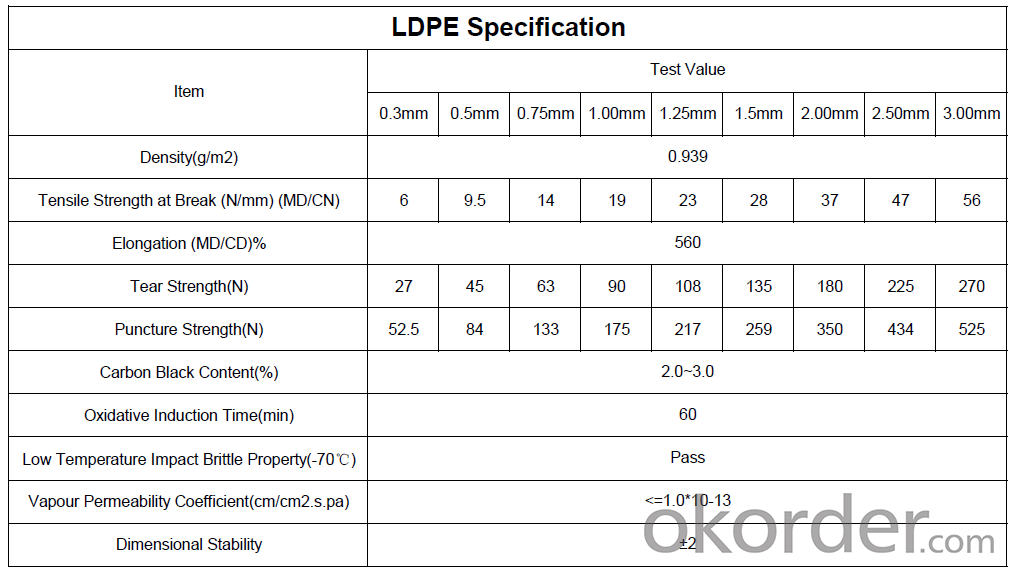

Product Specification

1)Material: LDPE/HDPE/EVA,etc

2)thickness:0.3mm~3.0mm

3)width:2m~7m

Product Package:

Product Package:

1. PE film inside, and Woven bag outside.

2. Packaged in container.

Product Application:

Product Application:

Landfill lining

Landfills capping

Water reservoirs

Pond-lining

Irrigation canals

Tunnels

Product Advantage

1.Some raw materials are produced by ourselves, or imported from overboard, so we could control the cost and quality to competitive in the market.

2. We have research team and laboratory, so we could research new products by ourselves and produce according client’s request.

3. There are more than fifty produce lines, so we could guarantee the delivery time.

4. We supply our products to many national projects in many countries, so our quality is stable and reliable.

5. If you have problem during your project when using our product, we could arrange our engineer to help.

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Are geomembranes resistant to hydraulic pressure?

- Yes, geomembranes are generally resistant to hydraulic pressure. They are designed to provide a barrier against fluid flow and can withstand high levels of hydraulic pressure without rupturing or failing.

- Q: European electrothermal?film is good

- European electrothermal?film is divided into high temperature and low temperature electrothermal?film. High-temperature electrothermal?film is generally used in electronic appliances, military, and now the electric film produced by science and technology. low-temperature electrothermal?film is a electric powered translucent polyester film, it can be heated from special electric conductive printing ink, metal carrier, after processing, hot pressing and made between the insulating polyester film. When working with electrothermal?film as a heating element, the heat is sent into space in the form of radiation , the human body and the object first get warm, and the combined effect is better than traditional convection heating. low temperature radiation electrothermal film system consists of power?supply, temperature?controller, adapting piece, insulating layer, electrothermal?film and finish?coat layer. Power supply via wires connecting the electric film, turning the electric energy into heat energy. Since the electrothermal?film is purely resistance circuit, so the conversion is high efficient, in addition to the loss of a small portion (2%), the majority (98%) is converted into heat energy.

- Q: Can geomembranes be used in pond covers?

- Yes, geomembranes can be used in pond covers. They are commonly used to create impermeable barriers that prevent water leakage in various applications, including pond covers. Geomembranes help to maintain the water quality by preventing contaminants from entering the pond and also reduce evaporation rates. They provide an effective solution for creating a protective barrier and promoting environmental sustainability in pond management.

- Q: Where does the smooth surface of seepage-proof geomembrane face?

- Negative direction that can increase frictions.

- Q: What are the typical costs associated with geomembrane installation?

- The typical costs associated with geomembrane installation can vary depending on factors such as the size of the project, the type and quality of geomembrane material used, site preparation requirements, and labor costs. However, on average, the installation costs can range from $3 to $15 per square meter.

- Q: Can geomembranes be used in floating fountains and decorative water features?

- Yes, geomembranes can be used in floating fountains and decorative water features. Geomembranes are impermeable barriers that are commonly used in various water containment applications, including lining ponds, lakes, and reservoirs. They can effectively prevent water leakage, maintain water levels, and provide stability for floating fountains and decorative water features.

- Q: What is the role of geomembranes in hazardous waste containment?

- Geomembranes play a crucial role in hazardous waste containment by acting as a barrier between the waste and the surrounding environment. They prevent the migration of contaminants, such as chemicals and pollutants, into the soil, groundwater, and nearby water bodies. The impermeable nature of geomembranes ensures that hazardous waste remains confined, minimizing the risk of environmental contamination and protecting human health.

- Q: How do geomembranes perform in high wind uplift conditions?

- Geomembranes generally perform well in high wind uplift conditions. They are designed to have high tensile strength and flexibility, allowing them to withstand the forces exerted by strong winds. Additionally, properly installed geomembranes have anchoring systems that help secure them to the ground, further enhancing their resistance to uplift. However, the specific performance may vary depending on the quality of the geomembrane material, installation techniques, and the severity of the wind conditions.

- Q: Can geomembranes be used in decorative ponds and water features?

- Yes, geomembranes can be used in decorative ponds and water features. They are commonly used as liners to prevent water seepage and maintain the desired water level. Geomembranes provide an effective barrier, ensuring the pond or water feature remains leak-proof and aesthetically pleasing.

- Q: Why HDPE geomembrane(high density polyethylene geomembrane) is the most frequently used impermeable?material among artificial synthetic materials?

- The most widely used among landfill impermeable?materials is HDPE geomembrane, more than 90% of the world's landfills are using high-density polyethylene geomembrane as impermeable materials. Among HDPE geomembranes, the imported products are superior, because geomembrane :1 good chemical stability, landfill leachate will not pose a threat to them; 2 low permeability, underground?water and rainwater dialysate will not permeate through the liner, and methane gas will not come out; 3 carbon black in HDPE enhanced UV resistance, which is plasticizer-free, solving decomposition exposed to ultraviolet light. So HDPE geomembrane landfill is the preferred choice of impermeable materials, and is also the most commonly used.

Send your message to us

PE Geomembrane LDPE/HDPE/EVA Geomembrane Liner for Landfills Capping

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords