HDPE Geomembrane for Earthwork International Geosynthetics

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

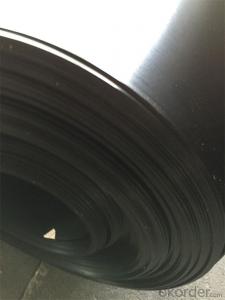

HDPE Geomembrane for Earthwork International Geosynthetics Introduction:

HDPE Smooth Face geomembrane are the preferred products for lining projects requiring low permeability, corrosion protection, exceptional chemical and ultraviolet resistance properties, which makes them extremely cost-effective for many applications such as waste landfill, storage reservoirs ,canals, powr plants in energy, vapor barriers, and waste water treatment in the line of industry and aquaculture and agriculture projects.

HDPE Geomembrane for Earthwork International Geosynthetics Specification:

Thickness | 0.12mm-4.0mm |

Length | 50m/roll,100m/roll,150m/roll or as your choice |

Width | 5.0m-7.0m or as your choice |

Color | White/Black/Blue/Green,mainly black |

Material | HDPE |

Delivery port | Qingdao |

Package: | woven bag or as customers' requests |

Product time | 2-20 days |

Features | 1.Good physical and mechanic performance |

2.High tearing resistance, strong deformation adaptability | |

3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance | |

4.Good adaptability to high and low temperature, non-toxicity, long service life | |

5.Good waterproof, drainage, anti-seepage and damp proof effects | |

6.Complete width and thickness specifications, low cost and easy installation. | |

Note | We can do as your demand,please feel free to contact us for more information |

HDPE Geomembrane for Earthwork International Geosynthetics Usage:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

Packaging & Delivery

| Packaging Details: | rolls,ctns etc. |

| Delivery Detail: | 20days |

HDPE Geomembrane for Earthwork International Geosynthetics standard:

No. | Item | Test Value | |||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 1.8mm | 2.0mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.94 | |||||||

2 | Strength at yield,N/mm | 11 | 15 | 18 | 23 | 27 | 30 | 38 | 45 |

3 | Strength at break ,N/mm | 21 | 28 | 33 | 43 | 51 | 57 | 71 | 85 |

4 | Elongation at yield,% | 13 | |||||||

5 | Elongation at break,% | 700min | |||||||

6 | Tear Resistance N | 93 | 125 | 156 | 187 | 219 | 249 | 311 | 373 |

7 | Puncture Resistance N | 263 | 352 | 440 | 530 | 618 | 703 | 881 | 1059 |

8 | Stress Crack Resistance, hrs | 400 | |||||||

9 | Carbon Black Content, % | 2.0-3.0 | |||||||

Carbon Black Dispersion | 1 or 2 | ||||||||

10 | Standard OTI Min | 100 | |||||||

High Pressure OTI Min | 400 | ||||||||

11 | Impact Cold Crack at -70°C | Pass | |||||||

12 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | |||||||

13 | Dimensional Stability (%) | ±2 | |||||||

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

Gemembrane Show:

\

\

- Q: welding specifications of composite geo-membrane.

- ①lap joint: lap joint width shold be 15cm; ② hot welding: Suitable for thicker geomembrane weld lap width of the substrate to 5CM. (Recommended bonding, soak the glue in water, poor seepage-proof effect.) digging the base into protective layer of mortar in the bottom of the lake(H20-30mm), slope cutting, dense and smooth composite geomembrane and vertical bulkhead, smooth pasted base surface, clear, step transfer of water pipe mouth sealed with sealing geomembrane laying welding and repair welding procedure handover quality acceptance, completion and acceptance of a high-level design: About 0.6m 2, waterproof construction total area is about 800㎡ 3,ceramsite brick built bulkhead, 4, collapse pit set by water

- Q: What's the geotextile wrapping the temperature humidity sensor of standard curing room for?

- The principle of geotextile wrapping on the temperature humidity sensor of standard curing room is almost the same, which is to cause the measurable properties changes by different temperatures. Such as the changes of heat expansion and cold contraction, and thermal resistance value. And then calculate the measured temperature according to their changing relationship. So, different sensors certainly have different working principle, but their basic principle of measurement is the same.

- Q: What is the role of geomembranes in saltwater containment?

- The role of geomembranes in saltwater containment is to provide a impermeable barrier that prevents the saltwater from seeping into the surrounding soil or contaminating nearby water sources. This helps to ensure the integrity and stability of structures such as saltwater containment ponds, reservoirs, or tanks, by preventing leakage and maintaining the desired saltwater levels. Additionally, geomembranes can also protect against corrosion, erosion, and other potential damages caused by the saltwater, prolonging the lifespan of the containment system.

- Q: What are the requirements for geomembranes used in heap leach pads?

- The requirements for geomembranes used in heap leach pads typically include high chemical resistance, durability, flexibility, and impermeability to prevent the leakage of leachate. They should also have excellent UV resistance, puncture resistance, and mechanical stability to withstand the weight of the heap and any potential settlement. Additionally, geomembranes used in heap leach pads should be compatible with the surrounding soil and have low permeability to ensure effective containment of the leaching process.

- Q: How do geomembranes contribute to the preservation of endangered species?

- Geomembranes can contribute to the preservation of endangered species by creating artificial habitats or containment areas that replicate their natural environments. These impermeable barriers help control water or soil quality, prevent contamination, and maintain stable conditions necessary for the survival and reproduction of endangered species. Additionally, geomembranes can be used in the construction of enclosures or barriers to protect habitats from human interference, invasive species, or pollution, providing a safe space for endangered species to thrive and recover.

- Q: Can the mobile phone stick the tempered film

- It is very good. The main function: 1, protect the eyes and stable visual acuity, it can prevent eye problem from the blue light of the screen! 2, The tempered film can prevent falling to protect the mobile phone screen and eyes.

- Q: What are the considerations for geomembrane selection in wastewater treatment plants?

- Some considerations for geomembrane selection in wastewater treatment plants include the material's chemical resistance, durability, flexibility, and compatibility with other components of the treatment system. It is important to choose a geomembrane that can withstand exposure to various chemicals and contaminants commonly found in wastewater. Additionally, the chosen geomembrane should have a long lifespan and be able to withstand physical stresses such as UV exposure, temperature fluctuations, and mechanical damage. Flexibility is also important to ensure the geomembrane can conform to the shape of the treatment system. Lastly, compatibility with other components such as pipes, valves, and fittings should be considered to ensure proper installation and functionality of the system.

- Q: What is the geomembrane material?

- Function: anti-seepage, isolation Product use: geotechnical dam, rockfill dam, masonry dam and pressure concrete dam; dike, dam front level anti-seepage cover, vertical foundation impervious layer; tailings dam, Roads, highways, railway subgrade; roadbed and other ground salt control; expansive soils; roadbeds, reservoirs (pit, kangang); waste land; subway, basement and tunnel, tunnel seepage lining; And waterproof layer of collapsible loess; roof leakage.

- Q: What are the considerations for geomembrane selection in agricultural irrigation systems?

- When selecting a geomembrane for agricultural irrigation systems, several considerations need to be taken into account. These include the type and quality of the soil, the water source and its chemical composition, the climate conditions, and the specific requirements of the irrigation system. Additionally, factors such as durability, flexibility, puncture resistance, and compatibility with other components of the system should also be considered. Ultimately, the selected geomembrane should be able to effectively prevent water leakage, minimize evaporation, and withstand the demands of agricultural irrigation.

- Q: Does a mist screen need to stick membrane?

- If the computer is equipped with mist screen, then there is no need, just use it directly. Film is only available in the mobile phone, no necessary in computer.

Send your message to us

HDPE Geomembrane for Earthwork International Geosynthetics

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords