Antiseepage Material 1.5mm HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description

Our product was proved as good physical and mechanic performance, high tearing resistance, strong deformation adaptability, puncture, aging, ultra-violet radiation, oil and salt, alkali and corrosion resistance, high and low temperature resistance, non-toxicity, long operational life, good waterproof, drainage, anti-seepage and damp proof effects, complete width and thickness specifications, low cost and simple construction.

1.used in landfill caps

2. base liner applications under roads, railways,

3.secondary containment for above ground tank farms,

4.as well as within various other containment structures such as dams, canals, ponds, rivers and lakes

5.They are also used for waterproofing of buildings and other similar structures.

2.Product Characteristic:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

3), Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

4), Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

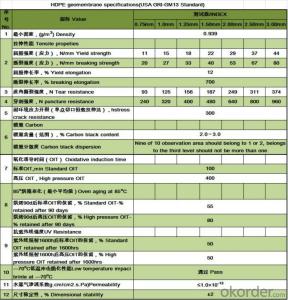

3.Product Specifications:

1.thickness : 1.5mm,

2.width: Within 8 m ;

3.longth:50-100m(as your request)

4.Material: HDPE

5.Color: Black ,white or as customer required

4.Reference Picture

- Q: Are geomembranes resistant to algae blooms?

- Yes, geomembranes are generally resistant to algae blooms. The impermeable nature of geomembranes prevents the growth and penetration of algae, making them an effective barrier against algae blooms in various applications such as pond liners, reservoir covers, and wastewater treatment facilities.

- Q: What are the considerations for geomembrane selection in fish farming ponds?

- When selecting a geomembrane for fish farming ponds, several considerations need to be taken into account. Firstly, the geomembrane should have high resistance to punctures and tears to prevent leaks and ensure the structural integrity of the pond. It also needs to be chemically resistant to withstand exposure to water, fish waste, and disinfectants commonly used in aquaculture. UV resistance is crucial to prevent degradation from prolonged exposure to sunlight. The geomembrane should also be easy to install and maintain, as well as cost-effective. Lastly, its durability and longevity should be considered to ensure the long-term success of the fish farming operation.

- Q: What's the construction method of soft film ceiling?

- 1. First to go to the site to see if there is a condition of installing the keel: Look at the scene to make sure the wall is completed, and woodworking processing part is qualified, the area that need to be plastered should be completed first. First part plastering carpentry part we proposed must be in accordance with the requirements to do, to advance the processing of.2. entering the construction site conditions Licensor hole size lamp, air outlet, first part is fixed according to the design Aluminum Alloy keel keel carpentry requirements drawing well, attention must be right angle connecting to smooth, flat, dense.3. lamp holder, tuyere, light tube plate to and around the keel level, and firmly cannot swing can smooth.4. smoke, ceiling lamps, the first position to make a wooden frame, wooden frame the bottom surface should be polished, and pay attention to the level of height is too low, it is easy to show a trace of.5. before installing ceiling, carefully check the keel joints are solid and smooth, the spray head to stick on the white tape, an outlet should be well handled. When loading the smallpox to first from the middle to both sides of the fixed, while paying attention to size on both sides and pay attention to welding seam to the final straight angle position, pay attention to smooth. Around the well to the smallpox pruning removes. To perfect income effect on the edge. Turn on the light hole. To mark the position of the lamp hole , and carefully stick the PVC lamp ring carefully and accurately on the bottom of the soft film and then remove the excessive smallpox after it is firm. Find the position of the outlet and the light pipe handicap, just as the surroundings, to install the soft film to the aluminum alloy keel, pay attention to keep the angle be smooth.

- Q: What exactly is the geomembrane? What are the applications?

- At the same time, alkali and salt corrosion, long service life; and non-woven fabric is also a kind of high-molecule short fiber chemical material. Geomembrane construction site its main mechanism is to use imperviousness of plastic film to cut off earth dam leakage passage, not only increases the tensile strength and anti-puncture ability of plastic film. They have good corrosion resistance to bacteria and chemical action, which is conducive to the stability of composite geomembrane and protective layer, with high tensile strength and extensibility, bearing the hydraulic?pressure and adapting to dam deformation with its large tensile strength and ductility, increasing the friction coefficient of the contact surface. And due to the roughness of the non-woven surface, geomembrane construction site its main mechanism is to use imperviousness of plastic film to cut off earth dam leakage passage; and non-woven fabric is also a kind of high-molecule short fiber chemical material, bearing the hydraulic?pressure and adapting to dam deformation with its large tensile strength and ductility, through needle punching or hot sticking forming, it is combined with plastic film, used in the dark place, not afraid of acid

- Q: How long do geomembranes last?

- Geomembranes can last anywhere from 20 to 50 years, depending on various factors such as the type of material used, environmental conditions, and proper installation and maintenance.

- Q: What are the design considerations for geomembranes in floating covers for wastewater treatment plants?

- Some design considerations for geomembranes in floating covers for wastewater treatment plants include the selection of appropriate materials that are resistant to chemicals, UV radiation, and punctures, ensuring proper installation and anchoring to prevent any leakage, considering the weight of the cover to ensure stability, incorporating proper ventilation systems for gas release, and accounting for potential expansion and contraction due to temperature changes. Additionally, considering the longevity and maintenance requirements of the geomembrane is important for long-term performance and cost-effectiveness.

- Q: What is the role of geomembranes in liquid containment?

- Geomembranes play a crucial role in liquid containment by providing a barrier against leakage and seepage. They are used in various applications such as landfill liners, ponds, reservoirs, and industrial storage tanks. Their impermeable and flexible nature prevents the penetration of liquids, gases, and contaminants into the surrounding environment, ensuring the safe storage and containment of liquids.

- Q: What are the requirements for geomembranes used in aquaculture ponds?

- The requirements for geomembranes used in aquaculture ponds include being highly durable and resistant to punctures and tears, being chemically inert to ensure compatibility with water and aquatic life, having low permeability to prevent leakage of water and chemicals, being UV resistant to withstand prolonged exposure to sunlight, being easy to install and repair, and meeting any specific regulations or standards set by local authorities.

- Q: What are the considerations for geomembrane installations in areas with high groundwater salinity?

- When installing geomembranes in areas with high groundwater salinity, there are several important considerations to keep in mind. Firstly, the choice of geomembrane material should be carefully selected to ensure it is compatible with the salinity levels. Some geomembranes may be more resistant to corrosion and degradation caused by saline water. Secondly, proper site preparation is crucial to minimize the risk of punctures or tears in the geomembrane. Conducting a thorough geotechnical investigation to assess the soil conditions and groundwater salinity levels can help in determining the appropriate measures to be taken during installation. Furthermore, it is important to establish an effective drainage system to prevent the accumulation of saline water beneath the geomembrane. This can involve using geotextiles or geocomposites to facilitate water movement and reduce the risk of hydrostatic pressure buildup. Regular monitoring and maintenance are also vital to ensure the integrity of the geomembrane over time. Regular inspections should be conducted to identify any potential issues such as leaks or degradation, and appropriate remedial actions should be taken promptly. Overall, careful material selection, proper site preparation, effective drainage, and regular monitoring are key considerations for geomembrane installations in areas with high groundwater salinity.

- Q: Can geomembrane bond with glass fiber reinforced plastics?

- Yes.

Send your message to us

Antiseepage Material 1.5mm HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords