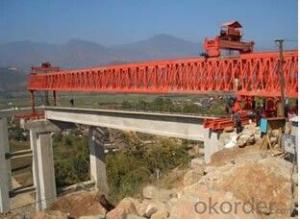

Launching Gantry / Beam Launcher

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This machine can combine 900 ton tyre trolley to work for double-line high speed Railway Bridge with box beams in the length of 20m, 24m and 32m. |

- Q: Now the high-speed rail bridge frame span of the beam

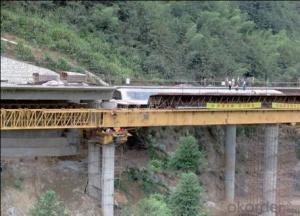

- Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down

- Q: Such as Title ah.....I am sorry that the steel structure

- 84798990 double beam bridge machine84798990 Longmen bridge erecting machine84798990 science and technology extension type double guide beam bridge machine84798990 special type Longmen bridge erecting machine84798990.90 bridging machine86040099 bridging machineI agree that your description is too simple, how to give you the appropriate coding? Best picture ah

- Q: Double guide beam bridge machine working principle

- Double island bridge erecting machine name by the two vertical beam, a transverse rod or beam between the two steel frame girder, common triangular truss, also in LCL beam, beam above a crane, following a leg, mobile

- Q: What kind of machinery is the bridge? Is the bridge crane or bridge crane? What is the difference between the three?

- And there is walking on the beam, or called the longitudinal displacement. The biggest difference between the bridge erecting machine and the general overhead traveling crane is that it needs to go through the hole itself

- Q: Bridging machine construction method? Common types of bridge machine

- Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down

- Q: Bridging machine rack in the front beam can beam block and padded timbers, whether there is stress between them.

- Is the bridge cap beam transverse member between pier and bridge superstructure, beam cantilever structure, can be single or multi span structure.

- Q: The difference between double guide beam bridge machine and single beam bridge machine

- Single beam bridge machine:The single girder bridge girder erecting machine adopts a single bearing beam, and the bridge erecting machine is composed of a single main beam, a supporting leg, a hanging beam trolley, a moving mechanism, a transverse moving mechanism and an electric control system. Main girder structure generally adopts box type structure of light weight, high stability of the beam, the guide beam can be moved up and down, back and forth, transverse, achieve a heavily beam beam falling in place, continuous erection line, line, curve and other different types of bridges.

- Q: How does the bridging machine work?

- If this thing can be explained with the image should be more clear

- Q: Above the highway bridge construction machine, in the case of the erection of the protective scaffolding, bridge construction can be opened to traffic

- Is it possible to allow someone or something else under the bridge machine during the operation.

- Q: What are the advantages and disadvantages of the overhead bridge erecting machine compared to the lower bridge erecting machine

- Compared with the downward bridging machine, the upper bridge erecting machine does not need to be laid

Send your message to us

Launching Gantry / Beam Launcher

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords