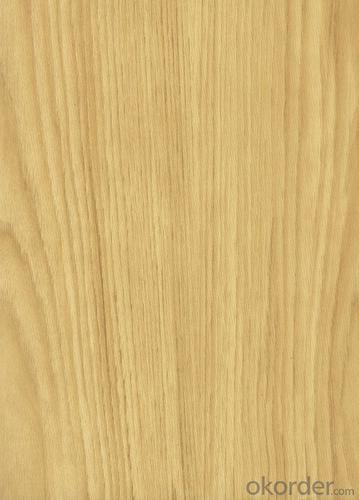

Laminate Flooring 8mm Export to Europe Engineering Flooring HDF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Laminate flooring is a multi-layer synthetic flooring product, fused together with a laminationprocess. Laminate flooring ismost often four layers of materials,From topto bottom is Durable Overlay, Decorative Paper, HDF board, Balance Paper.

Durable Overlay is made by applying an AL2O3 solution over transparent paper, AL2O3 is very fineand thus it does not hide the color and design of the decorative paper.

Decorative Paperis a computer made paper which imitates natural wood, stone etc, by applying AL2O3to decorative paper, the latter becomes protected from the environment.

HDF board are made of wood fiber compressed into a high density panel (≥880kgs/m3).

Balance Paper is the thick and strong paper treated with AL2O3 on the back of laminate flooring,it gives stability to the laminate flooring boards and provide a measure ofisolation from under-floor humidity.

Wear Rating:

Durable Overlay Thickness | Applying Place | Euro Grade | EN438 | EN13329 | China National Stand |

22g/m2 | 21 Family Low Grade | AC1 | 2000 | ≥600 | 1500 |

33g/m2 | 22 Family Medium Grade | AC2 | 4000 | ≥900 | 2500 |

39g/m2 | 23 Family High Grade | AC3 | 6000 | ≥1800 | 4000 |

45g/m2 | 31 Commercial Low Grade | AC3 | 9000 | ≥2500 | 6000 |

62g/m2 | 32 Commercial Medium Grade | AC4 | 12000 | ≥4000 | 9000 |

76g/m2 | 33 Commercial High Grade | AC5 | 15000 | ≥6500 | 12000 |

Formaldehyde Emission:E1

Moisture Content:≤12%

Surface: Mirror, Middle Emboss, Fine Emboss, Crystal, Hand Scraped

Specification:

Thickness: 7.3mm,8.3mm, 12.3mm, 15.3mm

Based on order, other specification are alsoavailable.

Packing: 8-10 pieces per carton, 35-60 cartons perpallet, about 20 pallets per container.

- Q: Is it good for solid wood flooring? Tangled. The

- Long rain off the blessing of the non-flap stone will hold the solid wood if you want to strengthen the durability of the price of rational selection of solid wood composite bar it has solid wood and strengthen the integrated advantages! Recommend several brands: Ankang long Sheng nature

- Q: Three layers of solid wood flooring and nine layers of solid wood flooring What are the shortcomings?

- Multi-layer solid wood compound with more, more formaldehyde. The Three layers of easy deformation, cracking room decoration in the general selection of three

- Q: can engineered flooring be used in a bathroom?

- Yes.. they can be so used.. but remember that water on an engineered flooring is not the best and in a bathroom, a flooring is more suseptible to having water on it.... I have always had tile in a bathroom and that is what I would recommend.. of if tile is not feasible, a good linoleum type flooring

- Q: Composite wood floor cracking with what glue is good

- With putty and paint mix well embedded cracks, can not bad for many years. There is a special floor glue, specifically in the pavement of wood when using a kind of adhesive, the function is that the floor can be firmly fixed on the cement base, so that the floor to increase the flexibility of foot feeling, more importantly, it can play Mute, waterproof moisture, anti-moth effect. General household complex wood floor cracking also has some commonly used other repair methods: 1, the old newspaper cut into debris, plus alum and water, boiled thick paste, and then use a knife to paste the paper into the cracks, Very solid. 2, with cotton or broken sacks burn ash, and then stir into the paste with raw tung oil, embedded in the cracks in the floor. After the dry can be very strong. 3, buy "bakelite powder" with a dish Sheng, drip into the water stir to the slurry, and then brush the cracks, a little spray into the water, fill in the bakelite pulp can usually be a night time bakelite pulp can dry Hard, wood flooring can be stamped as usual.

- Q: Do you want to play keel with solid wood flooring?

- There are four kinds of solid wood flooring installation methods: 1) keel pavement method: that is, wood keel and steel keel pavement method, this is the need to do wood keel. 2) Suspended pavement method: that is, the use of moisture-proof film or moisture-proof pad to install, this method is more popular way. 3) direct paste method is environmentally friendly floor glue paving method. 4) Wool floor bottom method. This is the main installation method of solid wood flooring, the installation method is different, need different tools and materials. 1) Before the floor is installed, the parquet is in place. The installer needs to check the number of floors and the number of accessories with the customer first, and check whether there is any damage, and ask the customer to confirm the signature. Then, to confirm the amount of floor, the ground flatness, the use of auxiliary materials, wait until everything is correct, and then install. 2) After installation must pay attention to acceptance, the main is the surface of solid wood composite floor should be clean, no burr, groove marks, corners without defects, paint fixed burning incense dredging Fugui feather Japonica full, no leakage paint, laying firm. Solid wood composite flooring can not play keel can be, however, solid wood composite keel will make the foot will be better, step up very soft.

- Q: My place where small, something more, had their own shop composite floor, do not know how to shop. Consult the knowledgeable master to help give pointers about, thank you! More

- Ready to hammer, and a board, each board to fight up when there will always be gaps, with a hammer pad with a knock on the board, the raft razed the drums can not directly knock on the floor, the floor will be knocked on the floor , Skirting line, then directly with glass glue it, a simple point

- Q: General composite wood floor life

- Home 10N maintenance of the better long, soak the words of 10 days to finish

- Q: See the figure, the bedroom is equipped with a composite floor, the threshold of the long piece of the cover is loose, if you do not want to find a master, their own solution, how to solve? What to buy to solve, how to solve? Hope to be able to get angry and angry engraved moxibustion smoked picnic easy to understand, simple and effective solution. The More

- This is very simple! This thing hurt the anger engraved moxibustion smoked puffing and shredding, will be removed, the gap in the clean dust, the original bar is also clean off the original glue, buy a glass of plastic, the back of the amount of hit, put in place, above It is best to place heavy objects fixed, 24 hours after the normal use.

- Q: My home on the 20th is just shop for the groom's 11.7 thick laminate flooring. The ground has a 60mm wide 300mm long 5-8mm drum kit. Because the master did not see the direct put the floor covered now walk in the above obvious feeling the middle of the two drums. Asked the shop that no problem flooring for several years will not be listed. After the resurfacing of the floor gap will be large, the floor may be more than the liver, I would like to ask the floor master. This problem with no need to open the floor to deal with the ground again shop. Reshaping what will be the problem, the floor seam will not increase the problem added: the floor did not glue. Press the edge of the plastic. He said the door to the special re-shop. But the floor can be more than the liver can be damaged (with door line) floor stitch may be larger than before. Are they right? There is such a big bag does not repeat the floor of the floor can do it, what the consequences of the floor more

- And the thickness of the relationship must not be re-shop just after the drum package will be more and more strengthened after the strong but the installation must be meticulous now, whether it is not locked floor businessmen do not glue to the customer environmental protection and product quality Impression can be a problem but not a small thing I suggest you hurry to reload the drums to get the local repair on the line is not trouble

- Q: what is the primary differences between 5/16 and 3/8 engineered flooring - besides thickness?

- The price.

Send your message to us

Laminate Flooring 8mm Export to Europe Engineering Flooring HDF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords