wood plastic composite decking floor wpc board price MADE IN CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

| Packaging Detail: | Packed with pallet. |

| Delivery Detail: | Within 2 weeks got the deposit. |

Specifications

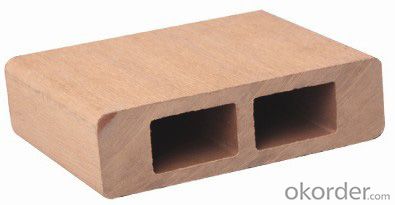

wpc decking

1.Place of Origin: CN; ZHE;

2.Features: Waterproof,Fireproof;

3.Application:park,garden.

4.Certificate: ISO 9001

3.Characteristics of WPC products

Wood plastic composite WPC decking manufacture

1.WPC decking environmentally friendly -100%recycled

2.WPC decking saving time-easy maintenance and installation

3.WPC decking longer usage/life cycle-pet resistant

4.WPC decking stronger and more flexible than traditional wood products

5.WPC decking standard woodworking tools can be used

6.WPC decking high degree of UV and color stability

7.WPC decking weather resistant suitable from~40-60

Features:

(1) Insect-proof

(2) Durable, economic.

(3) Cost low in maintenance.

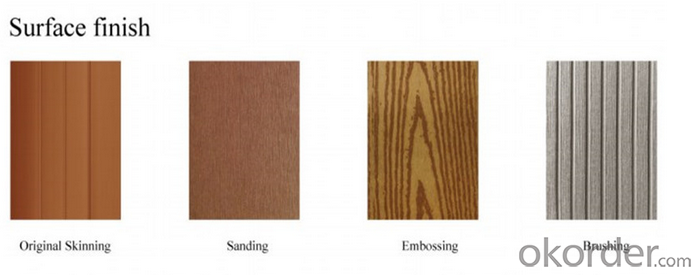

(4) Brand range of appearance and color.

(5) Environmentally friendly, recyclable.

(6) Looks and feels like nature wood.

(7) Easily and conveniently installed and cleaned.

(8)Stable over a wide temperature range, weather resistant,especially can be used in the open air.

Technical Index:

| Techinical Index | |||

| No. | Property | Result | Text Method |

| 1 | Density | 1.23g/cm | ASTMD792 |

| 2 | Water absorption | 0.50% | ASTMD570-00 |

| 3 | Tensile strength | 14.2Mpa | ASTMD638-03 |

| 4 | Elongation Rate at break | 3.90% | ASTMD638-03 |

| 5 | Flexural strength | 30.0Mpa | ASTMD790-03 |

| 6 | Flexural modulous | 3500Mpa | ASTMD790-03 |

| 7 | Linear expansibility | 4.9×10—5°C-1 | ASTMD696-03 |

| 8 | Compress strength | 26.4 | ASTM695-02 |

| 9 | Impact streght(unnotched)-25°C—+30°C | 90.1 J/m | ASTMD256-03 |

FAQ:

1.Price Term:FOB,CFR,CIF.

2.Port of Loading:Shanghai.

3.Payment Term:30% T/T in advance,70% balance against B/L copy.

4.Delivery Time:7-10 days after receiving your deposit for one 20 feet container.

- Q: Composite floor at home with the general election what brand and price, there is no concessions more

- Top 10 brands! Recently, 2008 China "top ten brands of high quality flooring" selection of the fall of the elephant, Feilinger, nature and other brands on the list. As of September 17, 58.32% of the respondents chose to use laminate flooring, 26.38% of consumers choose to use solid wood flooring, reflecting the strengthening of the floor and solid wood flooring market mainstream status. In the "you have used the floor there is no problem" in a, 92.19% of the respondents choose "no", indicating that consumers of Chinese flooring products, "ease of mind" higher. This event is sponsored by the China Building Materials Association, through the expert recommendation and network selection officially produced brand list 1, Del floor 2, the natural floor 3, the film Liner floor 4, blessing floor 5, macro resistant floor 6, Floor 7, up to the floor 8, the world and the floor 9, the elephant floor 10, Weiguang floor "This announcement the overall size of the top ten sampling brand, ranked in alphabetical order" Price that depends on what you need Kind of,

- Q: How does the composite wood floor rise?

- How does the composite wood floor rise?

- Q: How does the composite floor detect its density

- Do not need repeated bubble, you can use the weighing method to contrast. Strengthen the density of composite flooring to be detected, there is a relatively simple way is to weigh the size of the same size of small pieces of wood, and then calculate. Compared with the use of the same volume of 2 floor plate to say. Composite flooring, full name solid wood flooring. Is derived from the solid wood flooring family of the types of flooring, the first rise in Europe, the early 90s, the middle lead to China, generally divided into three layers of solid wood flooring and multi-layer solid wood flooring two categories.

- Q: Solid wood flooring really okay?

- General and E

- Q: What is the raw material of the composite floor?

- Is the sawdust! The And a mixture of glue!

- Q: Want to ask the solid wood flooring should be how to maintain my home is the "home of life" solid wood flooring, usually with a mop to play wet water smooth 粻 pull to save the chew chew to help the wedge blind dry drag the ground do not know this right? Need special care and care? More

- Solid wood flooring, can be maintained, you can not maintenance. Unlike the solid wood flooring (Chang 粻 pull to save the chew chew pillow blasting blind must wax). Usually wipe with a wet mop, not very good. The floor is often exposed to water, there will be water alkali attached, resulting in floor loss of light. Recommended to do the most simple maintenance: every six months rubbing orange oil --- remove the alkali, to restore luster.

- Q: Composite wood floor with tiles which tiles which point? Composite wood flooring with the wood floor as afraid of water? If mixed with the words, the bedroom with a wooden floor good? More

- Composite floor and floor tiles which depends on the use of occasions. If it is the living room, both can be used; if it is the bedroom, study, etc., the composite floor is more appropriate, more warm, tiles are blunt, relatively cold. If used in combination, the bedroom with the most appropriate wooden floor. Wood flooring is a natural material, with breathing, close to people, return to nature, can seat to sit, floor and lying, Dongnuanxialiang, used in the bedroom warm, warm, very user-friendly, composite floor and wood floor Sedan meter tamper is wood structure, so are more afraid of water, and because the structure of the reasons, the composite floor of the moisture resistance is less than solid wood flooring.

- Q: Multi-layer parquet, for geothermal, when the shop to shop moisture-proof pad? why? Do you want to play keel?

- (Generally manufacturers will lay the floor in the bottom of the laying of radiation film also play a role in moisture, the ground is not recommended to do self-leveling uneven) wood composite floor does not need to be Playing keel

- Q: What is formaldehyde in the composite floor?

- Formaldehyde is mainly from synthetic resin glue, is similar to the glue thing, used to link between layers and layers. You see the composite floor and the middle layer and the bottom layer are not the same bar, not the same description of the use of synthetic resin glue together. So like the above friends say, solid wood will also have formaldehyde, because the multi-layer solid wood also need to use it, such as our home Yi Jia multi-layer solid wood flooring. So the more layers the floor, the amount of formaldehyde may be more. But some of the surface of what other materials which may also contain floating fool first uncle Ying Jing scorpion thorn male formaldehyde. Of course, although with formaldehyde, the general content is also controlled below the national standard. Single solid wood flooring should be the least with formaldehyde it, but difficult to care, the shortcomings of variability. Some strengthen the composite floor of the formaldehyde content is relatively low, it is said that Yi Jia is, later regret to buy their solid wood, and solid wood to wax often trouble.

- Q: What is the height of the solid wood flooring and the composite floor after laying? How much is the solid wood floor?

- Keel generally have 3X float the first cut Ying electric charge nail japonica 4 and 4X5 and 4X4, single solid wood is generally 18MM and 20MM. After installation height is 6CM to 7CM. Composite flooring is generally 13MM to 15MM, plus mat 5MM, installed after 18MM to 20MM. Height difference 4CM to 5CM.

Send your message to us

wood plastic composite decking floor wpc board price MADE IN CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches