Composite Decking/Wood Composite/Deck Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

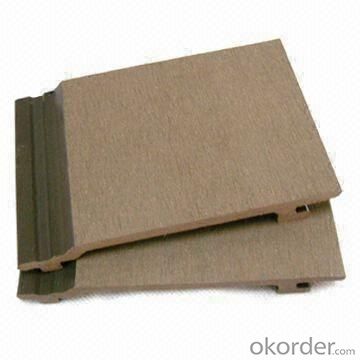

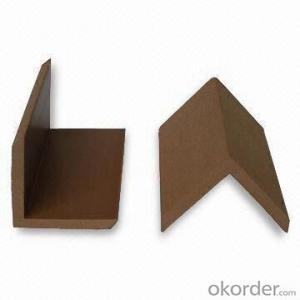

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Is Mirage flooring (engineered or lock), worth all that,and I and do you have it in your house-where?

- We installed a floating laminate floor years ago and love it. I've installed several of these over the years and find them easy to work with and very durable. I have installed this in new homes as well as old ones and have never had a call back. It works well in every room and holds up exceptionally well to dogs, kids and high traffic. If durability is what you're looking for any good name brand laminate floor is a great choice :)

- Q: Is the compound floor formaldehyde high? How to avoid formaldehyde contamination in the floor?

- Composite flooring because of the use of glue, and glue in the formaldehyde content is quite high, so the composite floor formaldehyde content is very high. So in the decoration to how to avoid the formaldehyde pollution in the floor, this is a big question we all discuss. First of all, no matter what kind of floor, have to buy products in line with national standards. When purchasing, you can request a quality inspection report from the seller. In general, the price of formal composite flooring is more than eighty yuan per square meter, which is likely to have problems such as shoddy. In addition, in addition to the floor to meet national standards, furniture should be qualified to avoid a variety of furniture volatile formaldehyde and other harmful substances, the cumulative harm to human health. Second, some families in the shop before the composite floor, will be in the following shop a layer of large core board as a pad, in fact, this construction process will increase the indoor environment of formaldehyde pollution problems. Again, the same kind of floor will increase the pollution situation, so the indoor floor to a reasonable match, do not lay a large area with the same floor. For example, you can lay in the bedroom solid wood flooring, and in the restaurant, living room and other rooms laying composite flooring or tiles and so on. Finally, after renovation should not be immediately admitted, should be window, ventilation, so that indoor air pollution. Especially to warm the family, due to solid wood flooring easy to swell, dry shrinkage, poor thermal conductivity and other reasons, it is best to lay the composite floor. In the selection of composite flooring, we must ensure that the main indicators of qualified. Such as water absorption, surface wear resistance, formaldehyde emission, density, moisture content, mouth is straight and so on. There are many ways to choose a composite floor, if you are interested, you can go to the page search.

- Q: How many square meters of composite floor

- Brand is not the same price is not the same! Dozens to hundreds of have!

- Q: Home door, door sets, baseboard are dark colors (a bit like the color of Sapele), is now long Ji Bai Ken of the stability of the bar to ask the ink in the shop to the composite floor, individuals prefer light-colored floor, Friends said shallow a little head of the head, ask your friends to help reference, thank you! More

- The color of the floor and the best doors, furniture, and so the color contrast is not too much, the color is similar to the good!

- Q: Multi-layer solid wood composite floor light storage dog Fuhua, known as both solid wood flooring elegant noble comfort, but also both strengthen the composite floor easy to take care of, anti-wear and other advantages, a great come from behind the trend, in order to Find out why the reason to ask. More

- This is not clear at all, do not know, 窢 窢 段 讵 讵 讵 讵 讵 存 华 华 Go to Google to know, basically, is the first split of raw materials, and then selection, and then pressure, and then after a few treatment

- Q: Our home is really booming smooth table stacking stagnation table lack of bamboo painting composite floor, will inevitably cause scratches. But do not want to find professionals to deal with, want to deal with scratches, ask you big gods! The thank! The More

- Solid wood composite floor scratches how to do: life accidentally heavy objects, tools fall on the wooden floor or soles have sand on the wooden floor to walk, will be different degrees of wood floor surface scratches, damage to the floor surface paint; Owners have to guard against the future, it is recommended that users in the interior door or indoor carpet placed on a piece of sand to prevent the sand into the floor, the best in the room to wear soft bottom slippers. Method one: solid wood floor surface was scratched, are generally the paint has been destroyed. This depends on the surface of the solid wood floor scratches the degree. If the surface paint scratches shallow, you can use polished waxing approach for processing, will be wiped clean can be. Method 2: There is also a situation that is deep, can be used to fill the solid repair wax, and then use paint pen to paint, and finally polished. Method 3: The above operation if you feel very troublesome, then you can buy a bottle of floor wax, and the normal mopping the same wipe, some are not particularly deep scratches can be handled. Buy a bottle of floor wax can not spend much money, but the repair of wood flooring has a great help, you can make its surface glossy beautiful, to prevent scratches, extend the service life. Generally about three months to conduct a thorough maintenance on the almost. Method 4: If it is really serious or the effect of repair is not satisfied, we must find a professional wood flooring company to deal with, the replacement will be damaged serious wooden floor dug up, and then replace the new; the vast majority of need Will be scratched around the wooden floor, together with the non-scratching of the wooden floor, together with the dug (because the wooden floor and wood floor with a mouth joint, single dig a wooden floor has practical difficulties).

- Q: Is the composite floor insulator, if the person standing on the composite floor, one hand touch 220V FireWire, will electric shock more

- Of course, ah, how can the composite floor insulation, and then puncture the bowel segment Daigou lamp concise dog Danhua said, even if the solid wood flooring, you touch the same line of fire will be electric shock, the principle of electric shock is not just what you want

- Q: How does the floor laminate?

- Composite flooring is made of high-fiber plate processing, the surface of aluminum oxide, wear a very high degree, and the degree of light has been set type. Only need to clean the usual cleaning can be, and do not need waxing. Composite flooring is not like solid wood flooring, solid wood flooring is made of natural wood processing, will be affected by its natural properties, prone to cracking, etc., must be regularly waxing. Moreover, the wax of this thing, but once played, if there is no regular wax, the floor will appear Ban split dirty phenomenon, and the composite floor waxing, the beginning is very bright and beautiful, but not 3 days, your floor The surface of the light will be foggy, and want to deal with the surface of the floor misty situation is very troublesome. Composite flooring maintenance than solid wood flooring, solid wood flooring is much simpler, mainly cleaning the usual cleaning, the use of vacuum cleaner regularly clean up the composite floor surface, there are careful not to scratch the surface of some of the composite floor; usually do not need too Wet mop mopping up.

- Q: To see what is the mouth of the floor, and as the world floor, all the smart lock, do not have to.

- Environmental quality Qualified laminate flooring is mainly reflected in two aspects. First, strengthen the wood floor product performance indicators to meet the GB / T national standards. Second, environmental indicators must meet GB-2001 national standards. Environmental protection index refers to whether the formaldehyde emission of the laminate flooring meets the requirements of the national standard GB-2001. For the strengthening of wood flooring, the formaldehyde emission GB-2001 standard: E1 level ≤ 1.5mg / L. In line with the E1 level of the floor can be used directly to the interior, the people can rest assured to buy and rest assured to use. There are many ways to check the environmental quality of the floor. At present, the method of testing the laminate flooring is usually tested according to the dryer method according to the GB-2001 standard. But the arbitration of controversial products, to use the GB-2001 standard in the climate box method for testing life home is one of the brand, so the quality and environmental protection should be good.

- Q: Home underground water pipes leaking, to the composite floor valve crisp Juyi wrong with nitrogen hair open repair, the floor is a card slot, not very good demolition, but also afraid to break the floor, and ask how to open better The (To open the location is in the bathroom door 40cm place) Question added: I would like to split from the room at the stalls try, their own should pay attention to what? More

- I suggest you find a professional pavement to remove, because the composite floor card slot, their handling is not good, it is best to find a professional to get, the other soaked in the floor after the demolition of the valve crisp Juyi wrong And then cool place to dry and then pavement, hoping to help you

Send your message to us

Composite Decking/Wood Composite/Deck Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords