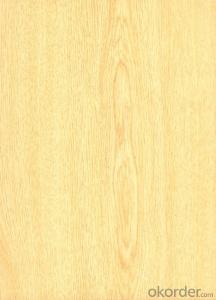

Engineer Flooring Laminate Flooring 8mm Export to Europe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Laminate flooring is a multi-layer synthetic flooring product, fused together with a laminationprocess. Laminate flooring ismost often four layers of materials,From topto bottom is Durable Overlay, Decorative Paper, HDF board, Balance Paper.

Durable Overlay is made by applying an AL2O3 solution over transparent paper, AL2O3 is very fineand thus it does not hide the color and design of the decorative paper.

Decorative Paperis a computer made paper which imitates natural wood, stone etc, by applying AL2O3to decorative paper, the latter becomes protected from the environment.

HDF board are made of wood fiber compressed into a high density panel (≥880kgs/m3).

Balance Paper is the thick and strong paper treated with AL2O3 on the back of laminate flooring,it gives stability to the laminate flooring boards and provide a measure ofisolation from under-floor humidity.

Wear Rating:

Durable Overlay Thickness | Applying Place | Euro Grade | EN438 | EN13329 | China National Stand |

22g/m2 | 21 Family Low Grade | AC1 | 2000 | ≥600 | 1500 |

33g/m2 | 22 Family Medium Grade | AC2 | 4000 | ≥900 | 2500 |

39g/m2 | 23 Family High Grade | AC3 | 6000 | ≥1800 | 4000 |

45g/m2 | 31 Commercial Low Grade | AC3 | 9000 | ≥2500 | 6000 |

62g/m2 | 32 Commercial Medium Grade | AC4 | 12000 | ≥4000 | 9000 |

76g/m2 | 33 Commercial High Grade | AC5 | 15000 | ≥6500 | 12000 |

Formaldehyde Emission:E1

Moisture Content:≤12%

Surface: Mirror, Middle Emboss, Fine Emboss, Crystal, Hand Scraped

Specification:

Thickness: 7.3mm,8.3mm, 12.3mm, 15.3mm

Based on order, other specification are alsoavailable.

Packing: 8-10 pieces per carton, 35-60 cartons perpallet, about 20 pallets per container.

- Q: What is the price of a composite floor?

- The price ranging from 60-170, the main stare riches whipped huhuan pet but the touch is the thickness of the wear-resistant layer there is a different substrate is easy to wear the board is not very good about 3 years will be a problem

- Q: Composite floor sound how to deal with

- Hello! Floor sound that there are empty holes, there may be keel uneven, you can contact the manufacturers. Hope to help you! Look adopted Oh

- Q: Yesterday forgot to turn off the water, so the two rooms of the composite floor Geng Gong blunt blossom yellow fake riveting all bubble in the water, and now the surface of the water has been disposed of, but there are water underground floor, the Internet Some people say that there is no big problem to dry, and some people say that the floor should be set off to dry the shop again, really do not know what kind of practice better, please help out, give suggestions? Thank you! More

- The experience of your home ah I have deep feelings, our home is just newly renovated the location of the bathroom door with water on the drums of the drums of the Genggong blunt bluish fade ripe, got the manufacturers of people that can give me But now it is too small, and I am too stupid, because my furniture are up, and re-shop the project is too vast, anyway, you see it, do not dry it will become the original Look, if not very obvious area is not big, then I think there is no need, but if it is too obvious that can only find the factory re-shop, you have to look at what to see if there is no drum! Simple advice hope to help you!

- Q: How does the composite wood floor rise?

- How does the composite wood floor rise?

- Q: Will the floor of the floor be poisonous?

- Composite wood flooring environmental standards, but there really do this harm. Composite wood flooring is usually 3 layers, 5 layers or more. Usually solid wood multi-layer composite, as well as non-solid wood multi-layer composite. Layer between the use of glue bonding. To warm the ground will promote the glue and woodworking boards and other artificial wood in the distribution of harmful substances. So if the home to consider the warm, it is best to use three layers of solid wood flooring, less glue content, solid wood does not exist harm.

- Q: I'm thinking of installing Schon Quick Clic engineered bamboo flooring (from Lumber Liquidators) in my basement. Does anyone have any experience with the product or the company? Thanks

- i would advise you not to use it in your basement if there is ANY composite materials in it. they say you can use it in damp areas but wood fibers+water=mold, so, even if it is 100% wood, i personally wouldn't do it. no matter how dry the basement appear there is always moisture and/or the potenial for moisture. on bamboo itself, is a great product and it is hard to go wrong with it. Thomas Edison built a concrete swimming pool in Fort Meyers, Fla. with bamboo as the reinforcement about 90 years ago. it is in like new condition today.

- Q: Fancy a composite floor above the standard: home 2 level. Ask the business is what, he said refers to the wear resistance ≥ 6000 turn. Is it right? More

- fake

- Q: Now the home of the composite floor ~ how much the general price ~ ~ ~ ~ ~ ~ ~ more

- Composite floor wood composite with enhanced composite, solid wood composite is generally 1.2cm thick, strengthen the general 0.8 thick, solid wood flooring a little more than 100 points, strengthen the composite a little better 7,80, 70 the best do not use the following, quality assurance can not.

- Q: Home composite floor with what wax the best maintenance

- The general floor of the wax can be, the composite floor of the requirements of this is not high !!

- Q: Composite flooring and tile prices which cheap

- Composite floor is divided into two kinds of hardening and solid wood, the cheapest 1.2 thick laminate flooring about 50 yuan / square meters. The cheapest 1.5 thick solid wood composite floor of about 120 yuan / square meters. Above has included artificial. Tiles is the tiles of the cheapest 60 * 60 each piece of 15 yuan. Plus artificial cement sand about 95 yuan / square meters. And so on, you can know the composite floor and tiles which cheap.

Send your message to us

Engineer Flooring Laminate Flooring 8mm Export to Europe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords