Hot Sale Wide Board Oak Engineered Wooden Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery:

Packaging Detail: Pearl foam +Cartons (neutral or according to customer's requirement)+ Pallets

Delivery Detail: 30 days after received the deposit

Specifications of solid oak flooring:

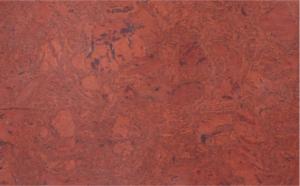

Hot sale wide board oak engineered wooden flooring/solid wooden flooring

Tongue and groove

UV lacquered

4 sides micro beveled

Hot sale wide board oak engineered wooden flooring/solid wooden flooring

1)Top veneer is oak, bottom material is plywood

2)Origin: China

3)Model: Multiply layer engineered wooden flooring

4)Size (mm):

910x125x12/0.6mm

910x125x15/0.6mm

910x125x15/2mm

910x125x15/3mm

5)Color:As customer's requirment

6)Grade: A or AB

7)Moisture content: 8%-12%

8)Joints: T & G , 4 sides are micro bevel 0.5-0.8mm

9)Surface finish: Gloss or Matt finished. Highly anti-scratched and abrasion resistance, UV lacquer coating; total 9 layers coating

10)Packing: neutral or according to customer's requirement

white oak engineered flooring description:

1. PPG glue or OSMO natural oil

2. Top layer: 0.6mm-6.0mm can make

3. Natural color or customized color

4. Surface treatment: Smooth or wire-brushed or hand-scraped

5. Tongue& Grove

- Q: Do you need to install a wooden floor? Do not have any harm

- Composite floor OKorder Geng high international 薨 huan arm for the force now do not need to install wood Leng. Now the solid wood composite flooring and laminate flooring are not wood Leng, the high practice is to lay the big core board base.

- Q: How much is the loss of a square floor to install a composite floor?

- Installation of composite floor wear and tear according to your room type to see, if your room type regular, loss is small, otherwise large. If your room is rectangular and long and wide exactly as the composite floor size multiplier, then there is no loss. Business or decoration companies are generally calculated by the loss of three percent, under normal circumstances should be more than enough.

- Q: Wooden floor installed for several days you can step on, solid wood and composite need to dry a few days? Because the urgent need to install curtains! The More

- Solid wood flooring installation is best after 24 hours and then step, which is a senior installation master said, should not be bad.

- Q: what is engineered flooring?

- Engineered wood, or a flooring, is a structurally strong wood made up of 3 or 5 plys ( usually 3) of wood. Each ply is crossed and glued to each other. The top ply usually made of the wood or choice such as oak, maple, cherry etc. The pcs themselves are mill to exacting standards or engineered to precise standards. Usually thinner than solid wood, anywhere from a 1/4 to 5/8 thick. These flooring are made to be installed in several ways to fit many needs, such as stapled, glued,or made into a floating floor system. Any questions you can e mail me through my avatar. GL

- Q: To warm on the floor can shop wood? What is the ground? To warm on the floor can shop wood? What is the ground? More

- To warm can not use solid wood flooring, can only use multi-layer solid wood flooring and laminate flooring. Because the solid wood flooring has a certain moisture content, if the warm Ji Fu irrigation Wong kill Hao ketone Han bundle heating, then the moisture content of the floor will be evaporated, will make the solid wood floor deformation!

- Q: Granville lion composite floor and giant Ning composite floor which is good

- Top 10 brands of flooring: Nature floor flooring Top ten brands of 2: Saint elephant floor flooring Top ten brands of 3: Ferguson wood flooring floor Top 10 brands of 4: Del Wood floor flooring Top Ten brands of 5: Wooden floor flooring top ten brands of 6: life home floor flooring top ten brands of 7: Rhine sunny wood floor flooring top ten brands of 8: security wood flooring floor of the top ten brands of the edge of the edge of the flag Luo wood flooring top ten brands of 10: Ruijia wood flooring nature Thank you

- Q: Do not be too expensive, hope is inexpensive. More than 100 yuan the best. More

- Longxiang Fengxi floor can also be! The price is not expensive

- Q: Multi-layer parquet, for geothermal, when the shop to shop moisture-proof pad? why? Do you want to play keel?

- Multilayer solid wood flooring installation whether to play keel, depending on their own circumstances. General multi-layer solid wood flooring playing keel, the foot feeling comfortable, more durable. But the cost of multi-layer solid wood flooring keel than other installation methods to be more expensive. First, the multi-layer solid wood flooring construction preparatory work: 1, the floor construction must be arranged at the end of all the decoration, in order to avoid other construction damage paint; 2, pavement floor must be dry, smooth; 3, Sprinkle a layer of mothproof powder. Second, the multi-layer solid wood flooring installation method: 1, straight paste method: like solid wood flooring installation, playing keel pavement; 2, straight shop method: the use of composite flooring method (that is, directly on the ground pavement); 3, high law: first on the ground covered with 62.5px thick pavement treasure. And then shop the moisture pad, and finally covered with multi-layer solid wood flooring.

- Q: Please tell me that the Kelly floor is good

- Composite floor water is the paper `` white is the cardboard to do `` `I was doing this decoration industry`

- Q: Home shop is a composite floor, five years, the recent total in the door seams found similar nibble sweater insects, dark red, big head small tail, the tail there are long hair, some hard, but also molting, a centimeter long, Ask the experts to answer what's going on? Began to think that the wool is born, and later found not, because the total appearance, clean up a seam, stop two or three days to see there, so I suspect the floor insects, and how to do? Why the composite floor will be raw insects? Home decoration is the ground Qinghu raft Hong Kong fan drum song attack card sweep is very clean, under the floor is the bubble and plastic, according to reason not raw ah, please professional answer! Other answers I have seen not suitable for me, do not paste it! The The More

- Insects need to have a certain degree of humidity and temperature, so if the floor of the insects, the vast majority of the reasons for the dampness of the disaster, so the key is pest control moisture. Experts, many users are paying attention to the surface of the decoration problems, and some hidden works are often overlooked, especially for the straight shop of wood flooring, the ground leveling is very important, the general hair is best to use dry powder to light , Because the hair of the exposed sand, but the temporary absorption of water, meet the appropriate environment will be the tiger raft Hong Kong drums wind attack card water release again. The dry powder can not only absorb the excess water can also play a protective film to lock the role of moisture, to prevent back tide, but also conducive to effectively measure the ground flatness. Some people think that the wooden floor pavement before the ground sprinkle a layer of charcoal, charcoal or pepper and other things can effectively prevent the insects, experts believe that this approach is not desirable. Charcoal, charcoal, although in the short term can absorb moisture, but does not digest the moisture, often again released, the same can not reach the purpose of moisture. And the practice of pepper is not desirable, usually dry pepper can be insect repellent, but many examples show that pepper is often caused by wet insects and then caused the floor insects. So, the best way is to do a layer of moisture to the ground to deal with, or more brush a layer of moisture-proof paint.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 24 Million |

| Main Markets | Europe; North America; |

| Company Certifications | ISO 9001:2008 ;IS01400:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% - 90% |

| No.of Employees in Trade Department | 700 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sale Wide Board Oak Engineered Wooden Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords