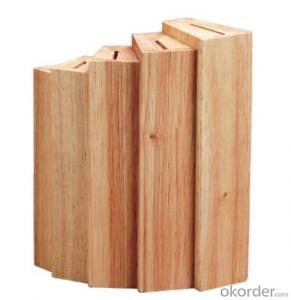

knife seat,F-KB051 rubber wood magnetic knife seat

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

MEAS:25*22*2.2cm

Key Specifications/Special Features:

Size can be customized

Can print your design of packing

Various styles for choice

Can print your design of packing

Small quantity order is accepted

We also have bamboo and plastic cutting board for choice

Our advantages:

All of our products are made by our experienced team of hard working artisans in a safe and responsible environment.

We take great pride not only in the outstanding quality of our products but also in the environment in which they are made

Every product that bears our name was made in an ethically and socially responsible way

Treated by high temperature, making our product antibacterial

Easy to clean, much durable and harder than other board due to the good material

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q: After the work of the machine tool, the knife is not changed, the time is good and bad, the circuit is not a problem, mechanical rotation is normal. What are the specific reasons

- Check your phone when the good or bad adjustment should be able to keep the turret is not in place after the rotation of the signal to detect the location of the sensor block or the location of the adjustment of your Holzer like

- Q: How can we remove the NC turret

- The first part of the rotation, two screws in the middle of the release, and then lock the 12 release of the knife rest, remember there are still under the four, in the middle of the road there is a flexible adjustment of the long screws

- Q: How to do the tool holder of the NC turret with too long time

- It is likely to be stuck inside the knife, first give it a break, and then pour some oil inside

- Q: What is the difference between NC machine tool and tool holder

- In front of the turret with rear turret X axis is not the same, the general system programming does not have what difference, the front turret program got rear turret lathe bed on the same processing, but also have different, like Beijing DTM window system, front and rear arc knife tool that is just the opposite.

- Q: What is the difference between the KSJ and HV

- The basic difference is that logo is different!! Others say the KSJ shelf is better than HV! But I think there's no difference!

- Q: CNC turret can be turned into 45 degrees ah? Can you turn counterclockwise?

- You mean it is not a simple numerical control of the car on the four bit, only in one direction, this may not be achieved, unless there is a problem. Eight knife position is the kind of post, you can, as well as 12 knives, each turn only about 30 degrees, you can choose the nearest, the direction of the two can be.

- Q: These possibilities have been tested, or useless

- Look at the oil tank is not dirty or oil is not enough to clean the oil tank filter, there may be poor oil absorption.

- Q: What are the parts of the lathe and tool holder

- A lathe is a machine with many parts assembled.A part of a lathe.

- Q: Is the plastic knife holder of roller skate good or metal knife holder good?

- It should not be adapted to the multi slip will be good at the beginning of the selection of a number of domestic imitation shoes cheap and durable more suitable for noviceC3 very heavy... Out of print now if the new shoes about 3000+ old words are not necessarily

- Q: What is the material of the cutting tool

- First say blade. Commonly used materials: 1 high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements. 2: tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than. 3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

Send your message to us

knife seat,F-KB051 rubber wood magnetic knife seat

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords