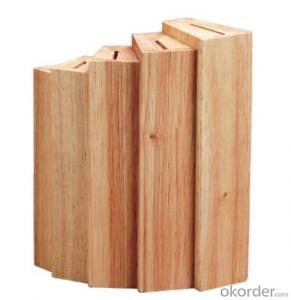

knife seat,F-KB041 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

N.W.:1.22kg

MEAS:22*15*13.5cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural rubber wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

- Q: CNC lathe turret in place how to do

- CNC turret repair more complex (personally think), I suggest you find professionals to repair

- Q: Oblique bed CNC lathe in the row on the turret mounted electric turret, and then install the power head, you can also install the tailstock, I do not know this? Cheap not?

- It seems that the tail frame can not be installed, loaded up is not much significance other can be installed at least 120 thousand or more

- Q: Tool holder S solution

- The bearing force is even and strong, the center of gravity of the s frame is low, the stability of the slide is stable

- Q: Is the plastic knife holder of roller skate good or metal knife holder good?

- Composite material FRAME (domestic said knife), with a certain flexibility, impact resistance, elastic.Metal materials FRAME generally use aluminum alloy. But there is a big difference in material selection. As we all know, aluminum alloy doors and windows are also made of aluminum alloy, aircraft wings are also made of aluminum alloy, therefore, do not blindly follow the aluminum alloy FRAME.Of course, the so-called composite material produced by too many factories in China, in fact, is the most basic plastic. I don't say much about the quality.Plastic, or metal, depending on how you play.Extreme roller skates have no full metal FRAME. And now the mainstream of the 7000 basic models of aluminum alloy.

- Q: Numerical control lathe tool holder does not match the system cutter number

- Is not the cover of the knife on the wrong side of the knife on the lid off

- Q: 4 station tool structure is the best. The detailed process of mechanical transmission, their demolition a few times, the worm brake to lift the knife. There is a problem in the rise of the knife in the process of the top cap of the spring to the top of the iron cover dead, the result of the death of the knife holder, can not drive. I estimate that the top cap and the angle and the first bevel on the iron cover are not consistent due to wear and tear. For I a person's opinion, hope you enlighten me

- 4 position tool holder structure of numerical control vehicle:Under normal circumstances can be fitted with 4 knives, the knife holder inside a worm with a turbineThe knife and the base on the contact surface of one end gear and two limiting block, the upper surface of the base two end face gear engaged normally a motor and worm shaft.The principle of 4 station tool holder for NC lathe:The knife is receiving the instructions in the form of pulse waves, when receiving a tool change instruction motor drives the turbine and worm. The worm to rotate the cutter knife up end gear separation, when the turret is elevated to a certain extent, together with the turret turret rotation worm together, rotate 90 degrees after encountering a limit block, because the motor power is blocked to when starting to reverse, the natural turret decline on the base end gear limit block lock, complete tool change

- Q: The difference between the tool holder and the electric tool holder

- The difference is that there is only one knife library, is T0101, if you want to use a few knives, that is, 02 or more behind the T01 can do it!The use of a knife is equivalent to a knife with a few different knife. Composite tool like, so when the knife changing electric turret is a knife with knife fill, in row knife, are the same, just change the knife cutter compensation and the same time, in different knife position input tool repair line. The first row tool change, T0101 knife, T0102 knife in front of the dabbler, unchanged.To row knife knife, if you want to T0101 the knife, put a knife to a knife or light near the end, directly in the 01 hit patch which according to the Z0 input, the outer circle is, what is the volume of just the tool compensation which according to the X.. Input, to second to third or more the knife is the same; but when to must put the numbers in the cutter compensation go to a knife, or otherwise useless.The tool holder is four knife library, to use a knife is T0101 or T0202.T0303.T0404. The two is not mixed with the.

- Q: The first reason is that the cutter shaft of the motor shaft is broken for a shaft / how long it will not be able to die!

- This problem is very simple, is not the command input, motor rotation, and the knife is like a rotation and stuck? This is just a tool conversion timeout, unscrew cap above the turret, turret removed, which has four pins, take out to see if bent, or flash, with the change of the pin, the pin can be used for standard parts can be, can not find it on 4mm head cut tail can be loaded

- Q: What are the advantages and disadvantages of CNC lathe turret

- Tool holder is a very important part of CNC lathe. The structure form of the general lathe for rotary cutter is mounted on the carriage along the circumferential direction, radial and axial turning tools can be installed, drilling and boring. The machining center can also be equipped with an axial milling cutter and a radial milling cutter. A small number of CNC lathe tool holder for the straight row type, cutting tool installed along a straight line.

- Q: How do you know how to install the roller skates?

- When installing tool holder is according to personal habits, but most were filled with the knife knife mounted on the middle sole. That is, the wheel is about the same length as the shoe.

Send your message to us

knife seat,F-KB041 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords