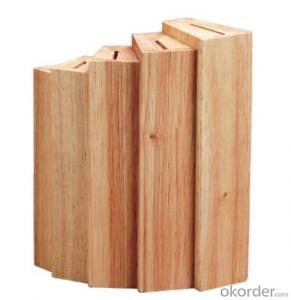

knife seat,F-KB039 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

MEAS:22*25.6*6.5cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural rubber wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: The cutting surface of the optical fiber cutter is like this, what's going on?

- I do not know if you are in the optical fiber welding machine is not the Japanese cutter, Sumitomo, whether or not, a knife can only be cut 6000 times, Sumitomo is considered good. Generally buy the welding machine with a knife. If you don't, you can only go back to one, because if you cut it off, you can only prove that it's not working. Is disposable. Only changing one, should not be expensive, you want to, you can't cut a few times, so that the fiber section is not smooth. In this way, the welding of the fiber as if it is not very high quality. Generally a good knife, cut out of the surface is smooth and smooth. In this way, the general quality of the fiber is relatively high. Can only change, repair, then bad repair!

- Q: Numerical control lathe tool holder is a tool to change what is the fault

- See what aspects of the problem, is the electrical problem, or mechanical problems, electrical problems, is the location of the magnetic switch to run, or the signal line is short. The mechanical problem is not in place, the first point of lubrication to see if it is caused by dry. If it is not, it is necessary to open the knife

- Q: To the signal line where the pull resistance, pull resistance to do with the trouble to say clearly?

- In a word: your signal circuit IC no internal resistance, protection. Pull the signal is determined by a high resistance resistor at the high level, while the resistance from the current limit, pull the same. Pull on the device is the injection current, the output current is down; just pull the weak and strong resistance, no strict distinction between what; for non (collector or drain) open circuit output circuit (such as gates) current and voltage capacity improvement is limited, the pull-up resistor is the main function of open circuit output type of circuit output current for the collector channel. All the pull-down resistor pull-up resistor is used in logic circuit, the circuit current is very small, the logic circuit of MOS tube bias current is microampere, even pA uA, the current level to provide a desired level, such as the current level without any output, because there is a pullup resistor so after a level is actually connected to a high level. Power amplifier circuit with no pull down resistor. Pull the signal is determined by a high resistance resistor at the high level, while the resistance from the current limit, pull the same. The pull-up resistor is the main function of the open circuit output current output channel for the collector; main function is connected with the pull-down resistor resistor together to line in the closed circuit driver (node) to a fixed level. Pull on the device is the injection current, the output current is down to note is that the pull-up resistance caused by too large delay output level, including the choice of the principle of resistance: 1, from the current irrigation ability to save the power consumption and chip considerations should be large enough; resistance...

- Q: How to install CNC machine tool

- Vertical turret mounting(1) open the guide strip and press plate on the cutter holder, clean the guide rail and the processing surface, check the guide rail surface should be intact without rust.(2) the left and right vertical turret respectively with lifting beam, with oil on the rail surface, the gear transmission is to mobile tool beam assembly hole, mounted on the plate, strip, slide clearance adjustment.(3) the vertical shaft of the vertical cutter head is installed, and the compression member of the balance hammer is removed, so that the counterweight is balanced.

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The turret of the numerical control lathe is the front knife holder in the operator's side. The common lathe is the rear cutter. When the tool head, the G42 tip radius compensation right bias in the car when the hole, when the car is round with G41.

- Q: What is a tray roll bag

- Super large PE bag (tray bag, tray roll bag, super PE even roll bag): for the industrial production of super large PE bag, super PE roll bag.The utility model is mainly used for the packing of the pallet goods, various Super machinery, the packing of the goods, and the waterproof leakage proof of the swimming pool and the related buildings. Available for various specifications, various forms of super Dalian roll bag. The work efficiency is effectively improved, and the labor intensity is lightened.Material; PE, aluminized film, shrink film, etc. can be produced according to customer requirements. Maximum size; 8m/36m bag shape; top opening, side opening, m side, etc..

- Q: What is the difference between the tool holder of the CNC machine tool and the horizontal lathe

- Lathe is generally more than a knife, a good point of the lathe is also used 8 knife turret, machining center with a knife library

- Q: What is the difference between numerical control tool holder and power tool holder

- CNC turret is a large class, which includes the common tool holder and power tool, that is, the power tool holder is one of the numerical control.The common tool holder can only be installed with a fixed knife seat for processing, the power tool holder can be installed with a fixed knife seat, and a power knife holder can be installed.CNC turret is an auxiliary device for CNC lathes are the most common, it can make the CNC lathe in clamping a workpiece in many or even all of the machining process, to shorten the processing auxiliary time, errors caused by multiple workpiece reduce machining process, thereby improving the machining efficiency and high precision machine tool.At present, the domestic CNC turret to electric, divided into two types of vertical and horizontal. Vertical tool holder has four, six stations in the form of two, mainly for simple CNC lathe; horizontal tool holder has a position of eight, ten, twelve, can be positive and opposite direction rotation, the nearest election knife for the full function CNC lathe. In addition, the horizontal tool holder is provided with a hydraulic tool holder and a servo driving tool holder.

- Q: The direction of the tool head and the tool head of the NC lathe

- G41g42 use the judgment of the tool tip is not the same as you this figure to 09 knife point for the center of the rotation of 180 degrees is the rear tool head position input value evaluation standard front and rear is the same as the input value

- Q: What is the material of the cutting tool

- First say blade. Commonly used materials: 1 high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements. 2: tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than. 3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

Send your message to us

knife seat,F-KB039 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords