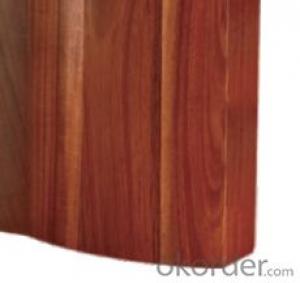

knife seat,F-KB016 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:1.872kg

MEAS:25*16*11cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: How to install CNC machine tool

- Vertical turret mounting(1) open the guide strip and press plate on the cutter holder, clean the guide rail and the processing surface, check the guide rail surface should be intact without rust.(2) the left and right vertical turret respectively with lifting beam, with oil on the rail surface, the gear transmission is to mobile tool beam assembly hole, mounted on the plate, strip, slide clearance adjustment.(3) the vertical shaft of the vertical cutter head is installed, and the compression member of the balance hammer is removed, so that the counterweight is balanced.

- Q: Drilling out of the hole is the overall deviation, the hole is 0.15, the cutting tool angle is not biased, the product is not how to jump, I was the first drilling after the chamfer, is how to go wrong, in this case, ask the teacher, thank you first, urgent...

- Perhaps the clamping part is not strong, you look at whether the clamping, three claws excessive wear.Recommendation: 1 check the three claws.2 hydraulic chuck, increase pressure.3 chamfer first, then hit the center hole.

- Q: NC turret is not in place

- The switch of the tool holder (the encoder or the encoder) is loosened and displaced.First manually pull the motor rotation, so that the tool holder is in position, in the system diagnostic interface to view the cutter position signal, back and forth rotation of the tool holder switch, so that the current knife position signal in the diagnostic page display, and then tighten the tool holder switch.One more word, position detection in ordinary turret is actually a switch, just a different type, divided into contact and contactless or integrated multi position switch, and can not complete the encoding encoding, is in the NC system, called frame encoder has high technology content, the price is much more expensive. The knife switch is not worth some money.

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The turret of the numerical control lathe is the front knife holder in the operator's side.The common lathe is the rear cutter.When the tool head, the G42 tip radius compensation right bias in the car when the hole, when the car is round with G41.

- Q: What is the difference between the NC lathe and the tool post

- The opposite direction of arc G02/03 rotation, the rest are the same

- Q: What are the parts of the lathe and tool holder

- A lathe is a machine tool which is mainly used for turning a rotating workpiece. Can also be used in the lathe drill, drill reamer taps Banya and knurling tools for the corresponding processing.The cutter head is composed of a plurality of layers of tool holders, whose function is to clamp the cutting tool, and to make the cutting tool move longitudinally, transversely or obliquely.

- Q: The difference between the tool holder and the electric tool holder

- The difference is that there is only one knife library, is T0101, if you want to use a few knives, that is, 02 or more behind the T01 can do it!To row knife knife, if you want to T0101 the knife, you put a knife to a knife or light near the end, directly in the 01 hit patch which according to the Z0 input, the outer circle you have, what is the volume of just the tool compensation which according to the X.. Input, you want to second third or more knife is the same; but you must take the time to fill in to lose in the digital knife to a knife, or otherwise useless.The tool holder is four knife library, you want to use a knife is T0101 or T0202.T0303.T0404. The two is not mixed with the. Hope to help you.

- Q: CNC lathe hit the knife after the knife center height, how to deal with?

- Turret positioning pin deformation! Contact factory maintenance

- Q: CNC machine tool can be drilled hole how to center

- Find a good car end cars to X0, change bit

- Q: What is the reason why the turret of NC lathe is not maintained?

- First, the bad disk, this may not be great.Two, the inside of the positioning pin broken.Three, the hollow shaft fracture.

Send your message to us

knife seat,F-KB016 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords