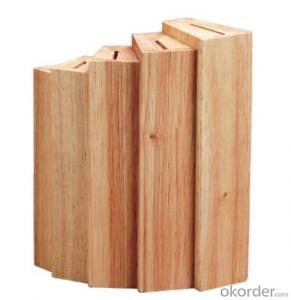

knife seat,F-KB026 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

MEAS:24*21*11cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: CNC lathe turret, sometimes why turn around.

- The position of the relay behind the knife is not right, it is generally far away from the knife position, so there is no servo feedback signal, so that the tool holder is not to stop, adjust it. I'm not looking for an electrical repairman.

- Q: CNC lathe turret in place how to do

- Tool change:1, the machine tool holder after the knife, the knife is a mechanical problem, the center of high deviation2 turret Rihall element, proximity switch, encoder, damage. Or poor contact, or 24 volt supply knife is not normal.3 according to the different types of tool holder, check the tool manual, with the electrical schematic diagram and ladder diagram to find out the cause of the fault.

- Q: Why is the number 980 CNC lathe turret always turn and then alarm

- Tool holder is always unable to find the knife position, usually 24 or 0 volts knife restIf it is a station can not find the detection switch is broken

- Q: What is the difference between the KSJ and HV

- Far, the accuracy of the KSJ knife, the quality is much higher than the HV, the price in that bad! But I'm talking about genuine

- Q: Tool holder S solution

- Vertical typeThe wheel frame, in fact, is a parallel steel frame structure.Than S, there are many advantages.For example, solid, DIY, modification, etc.

- Q: These possibilities have been tested, or useless

- Spend some money, from bending machine manufacturers please a teacher to do.

- Q: 1, CNC horizontal lathe tool holder with front and rear respectively. CNC vertical lathe tool holder how to classify?2, no matter front or rear CNC lathe, cutter movement from right to left (along the Z axis) with G42 compensation?

- In the tip of the compensation bar to enter the radius of the tip of the knife is good, of course, we must first know the radius of the tip of the nose,

- Q: The rotary tool holder is marked with the knife number. How to define the knife number?

- With the actual number of the same number of tools directly in the set of parameters can also be set up in the program

- Q: CNC lathe hit the knife after the knife center height, how to deal with?

- Turret positioning pin deformation! Contact factory maintenance

- Q: How to return to the ordinary lathe tool

- Remove and check whether the spring pin back position is smooth (with the hands of the press about 20 times). Take a look at whether the end of the spring pin has been seriously worn, the same knife bottom surface is also turned over to see if the limit groove is also serious wear.

Send your message to us

knife seat,F-KB026 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords