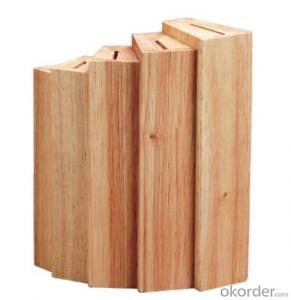

F-KB035 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

N.W.:1.572kg

MEAS:21*19.5*6cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural rubber wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

- Q: Numerical control lathe tool holder is a tool to change what is the fault

- It should be blocked to form the motor overload, the method is verified about CNC lathe turret and motor out, if not the normal disc worm that is stuck to the machine, can be disassembled in accordance with the instructions of disassembly tool, check the internal parts to see if there is deformation coupling and so on because, in many cases is mechanical clamping due to collision deformation.CNC lathe: CNC lathe, also known as the CNC lathe, that is, computer numerical control lathe, is China's largest use, the most extensive coverage of a CNC machine tools, accounting for about 25% of the total number of CNC machine tools. A set of mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology as one of the integrated mechanical and electrical products. Has the advantages of high precision, high efficiency, high automation and high flexibility for manufacturing equipment in machine tools.

- Q: Drilling out of the hole is the overall deviation, the hole is 0.15, the cutting tool angle is not biased, the product is not how to jump, I was the first drilling after the chamfer, is how to go wrong, in this case, ask the teacher, thank you first, urgent...

- The overall mean partial is specific bit big?1 first check the bottom of the hole with the size of the hole is the same if it can not be determined for the drill bit tilted2 drill bit size is not accurate in general has a few wire error is normalIf you are talking about the normal eccentricity the central axis of the hole is not a shaft with the central axis of the workpieceSo it is the problem of the chuck first clean the chuck jaws necessary when the car can claw a knife and then try to solve the problemIf not, that's the problem with the chuck assembly

- Q: Oblique bed CNC lathe in the row on the turret mounted electric turret, and then install the power head, you can also install the tailstock, I do not know this? Cheap not?

- Row lathe generally does not install tailstock, it will lose the advantage of the knife.Others can be added, according to the need to add, not excess.

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The operator is standing in front of the numerical control lathe, the cutter head is located between the main shaft and the operator. When the tool spindle is rotating, the tool head is turned upward, and the cutter head is rotating. The front and rear turret turret programming is the same, clockwise and counterclockwise circular interpolation G02 interpolation G03 direction is right according to the Descartes coordinate system, first determine the positive direction of the Y axis, and then from the positive direction of Y in the negative direction seems to determine the positive direction of the X axis, and then determine the G02 and G03 in the direction of the XZ plane can be, in front of the turret Y positive axis down, rear turret Y positive axis upward. No matter what the system is the same, if you in the right direction according to the right to see Descartes coordinate system can determine G02 and G03 in the front and rear turret style the same, the Y axis is a virtual axis lathe, there is practically no Y axis.

- Q: Tool holder S solution

- Modified DIY it certainly is h good, can change the surface of bamboo wood aluminum can, spray painting stickers can... The support of the s arm than the low end of the non uniform force... The actual s arm didn't what reinforced technology, the most vulnerable to bad is that even if you part of aluminum, steel shaft intact, aluminum bent??? From the point of view of the wheel easy disassembly, s frame is much better, less two outer shaft on the convenience. As for the slide is more dependent on the wheels and bearings, s frame is close to the center of gravity of the Double Tour dragon board, h's center of gravity close to the long plate in the skateboard, of course, the difference is not so big, more difficult than the long board.

- Q: For what parts of the process, what is the difference between the installation

- With the knife is like a long knife, to prevent the use of knives to make the knife, the center frame is used for the processing of slender shaft, to prevent the processing of slender shaft shape into the middle of the coarse two fine

- Q: What are the advantages and disadvantages of CNC lathe turret

- The radial direction (X direction) of the cutter head is to retreat to the operator. The utility model has the advantages that the knife is convenient and the price is cheap; the disadvantage is that there are only four cutter positions.The rear cutter holder is a tool holder which is used for withdrawing the knife from the radial direction to the opposite direction of the operator. The utility model has the advantages that the cutter position is more than the front cutter holder, and the loading and unloading work piece is convenient. The disadvantage is that the price is expensive.

- Q: CNC machine tool can be drilled hole how to center

- 1, do not need to set the coordinate system (the center), is loaded with a knife, in the process of preparation of processing requirements, reasonable adjust the height and verticality, the proper use of speed and feed rate, the knife tool can be set, simple, can fix a hole.2, if the degree of difficulty and high requirements, please use the circular drilling instructions programming.

- Q: Where are the Holzer elements in the CNC turret?

- Holzer components in the tool holder is called a disk. I have a detailed look at the space

- Q: What is the function of the tool on the turret of NC lathe?

- The angle of the adjusting tool post is only temporary change, and the position of the tool post can be repeatedly positioned after the rotation of the tool holder!

Send your message to us

F-KB035 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords