K 16X22X17 Needle Roller Bearing Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

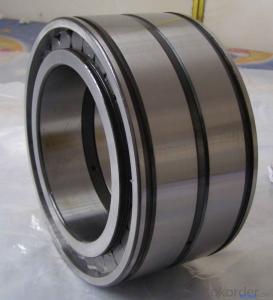

Product | Best Price Needle Roller Bearing K 16X22X17 |

Precision Rating | ABEC1,ABEC3,ABEC5 |

Clearance | C0,C2,C3,C4,C5 is available |

Sealed Cap | Rubber or Metal |

Paypal | Acceptable |

OEM | Accept |

Vibration Level code | V1,V2.V3 |

Material | Gcr15 |

Seals Type | ZZ/ZRS.RZ/RS. Open |

Mass | 0,00138kg |

Bore Size | 16 mm |

Outside Diameter | 22 mm |

Hign | 17 mm |

Regular export packing | Plastic drum+White box+ carton |

industrial packaging or as your requirement | |

MOQ | 1 pcs |

Delivery Time | 3-7 days after receiving your payment |

Payment Terms | L/C,T/T,Western Union |

Port of shippment by sea | Shanghai,guangzhou,qingdao |

Place of Origin | China |

Samples | Available |

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Product Advantages:

1.Bearing Manufactory ( Have our own technical department)

2.High quality products (Long Life and low noise)

3.Well-daserved Reputation (Good Stock Guarantee)

4.Professional service ( Promptly shippment)

5.OEM Service,Sample is available

Packaging & Delivery

Packaging Details: | 1.industrial packing |

Delivery Detail: | in stock or 15-30days after P.O |

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q: What are the differences between needle roller bearings and cylindrical roller bearings?

- With the same diameter, the needle roller bearings have smaller radial sizes and smaller carrying capacity.

- Q: I'm thinking about buying an 87 Fiero for $650 but it needs rod bearings... I wanna know if it's worth it to buy it.

- Engine would have to come out of the car to replace rod bearings so there would be a fair amount of labor involved in just getting the engine out. Its also unlikely that just the rod bearings are bad, usually if the rod bearings are bad so are the rod journals on the crank and then you have to wonder about the rest of the engine. If you like the car otherwise I would figure on getting a rebuilt engine. Price out a rebuilt engine and then the cost to install it and use that number to decide if you are going to buy the car. If you do get the car take it to a shop and have em pull the motor and have a look at it. If its worth fixing have em fix it if not you are not out anything extra since you would have had to remove the old one to install the rebuilt one anyway.

- Q: My wife has a 2005 Nissan Quest Minivan and this is the second time I had to have the front wheel bearings replaced. First set was at 40K and now again at 90K. Is aggresive accelerating/braking the main cause for this condition? My wife drives like Danica Patrick on crystal meth!

- The bearings has nothing to worry about accelerating, braking etc. now, bearings needs to be lubricated and do not be immerse in water , also at installation need to be clean, lubricated with the recommended lubricant and clean, any foreign material will destroy the bearing overtime. A well maintained bearing should last the life of the car....

- Q: recently my grease ball abec 5 have rusted and it is time for new bearings. which ones should i get. i am looking to spendo no more than 35 bucks

- skateboarding is gay.

- Q: Needle roller bearings are how to process the needle, so smooth finish?

- The process of needle: blank forming, deburring, heat treatment, coarse and fine grinding, end rolling surface, super finishing rolling surface polishing or sawdust.For flat head or taper head needle roller, such as blank forming, it is difficult to guarantee the length and size tolerance, and the grinding double end process can be increased. If the convex generatrix rolling surface is needed, it can be carried out directly in the process of super finishing, rolling or channeling.Needle roller bearing (needlebearing) is a roller bearing with cylindrical roller, relative to its diameter, the roller is thin and long. This roller is called needle roller. Although it has a small section, the load bearing capacity of the bearing is still high, with thin and long needle bearing roller (roller diameter of D = 5mm, L/D = 2.5, L roller length), so the radial structure is compact, the minimum diameter of the diameter and load capacity and other types of bearings, bearing the same, especially for the radial installation size limited. According to the use of different occasions, can choose the inner ring of the bearing or needle roller and cage assembly, the shaft neck surface and the surface of shell holes matched with a bearing directly as the bearing inner and outer rolling surface, in order to ensure the load capacity and operating performance and have the same ring bearing, shaft or housing bore raceway surface hardness the machining precision and the surface quality of bearing ring raceway and similar. This kind of bearing can only bear radial load. The needle roller bearing for stamping outer ring is needle roller bearing with thin stamping forming outer ring.

- Q: i just found my skateboard after about 5 years and two of the wheels are rusted and wont move. im working on replacing the wheels and bearings, but the two rusted wheels still wont come off i was able to get the bolt off of one and it now spins, but thats about it. its been soaking in coke all week and i bought wd-40 today and used that.

- buy new one if rusted - you don't ride it - so buy new one let it rust to

- Q: Ive put some 18 wheels on my car (which shouldnt be a problem because I know people with bigger ones on a golf) as soon as they went on, the car makes a howling noise from the front, a bit like a wheel bearings gone, or they are catching on something? There are no scuff marks on the wheels or tyres and I got a mechanic to check the bearings and they are fine, It sounds worse when the car is slowing down, ive also had the wheels checked and balanced, there is nothing wrong with the alloys but one of the tyres was slightly mis-shapen but ive been told thats not the problem, any ideas please? Dont feel safe driving it until I know whats causing itThanks

- Hi, the front wheel bearings on the golf's are not a tapered type and are very hard to check for freeplay / wear when car is jacked up...I have worked for VW for 30 years and changed many of the front pressed in type bearings....the only sure way of testing which side bearing is noisy is to spin the wheel up to a high speed with car jacked up and feel the bottom of the shock behind the wheel hub were the hub is bolted to it, if the bearing is worn you will feel a grinding sensation through the hub. This can be very dangerous if you are not careful....we used a mobile wheel balancing machine to spin each wheel up while, it was jacked up on one side... I would not try this if I was you with no training...Get a 2nd opinion from your local VW specialist or come and see me if you are in NW UK...

- Q: i shanged all the bearings and it ran fine for 20 minutes then started spitting and shaking and making pfft noises when i hit the gas.like this vrooom pfft vroom pfft pfft vroom offt pfft pfft pfft bang pfft pfft vroom. if that makes sence lolso im thinking its the timing or the engine is not good any more.DO YOU THINK ITS THE TIMING?and can you refresh my memory on tdoing timing?make sure the number 1 cyl is up and the distributor is in the number 1 possition. then make sure its just barely over top dead center and thats about it right?

- could be timing or something as simple as split in inlet pipe did you use a strobe light?

- Q: how to replace front wheel bearings on AWD vehicles?

- There are inner and outer bearing. You pull the rotor... sometimes you must break loose the spindle (comes out of the CV joint) and all recommend a puller. Same as doing the front for most cars, just all the way around.

- Q: f-250 changing front wheel bearings?

- Well, what's the problem? Do you need to know how to do it? How much it cost? What are wheel bearings? You have tapered bearings. When they go bad you change the inner and outer bearing plus wheel grease seals then get them repacked. Sometimes you can just have them tightened and that fixes it

Send your message to us

K 16X22X17 Needle Roller Bearing Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords