High-Temperature Insulating Fire Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulation Fire Brick

CMAX Insulation Fire Brick are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

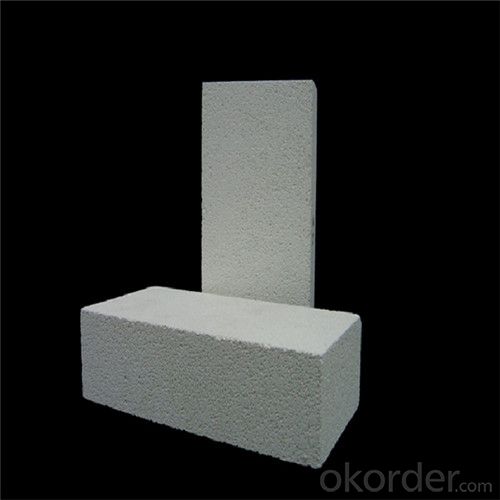

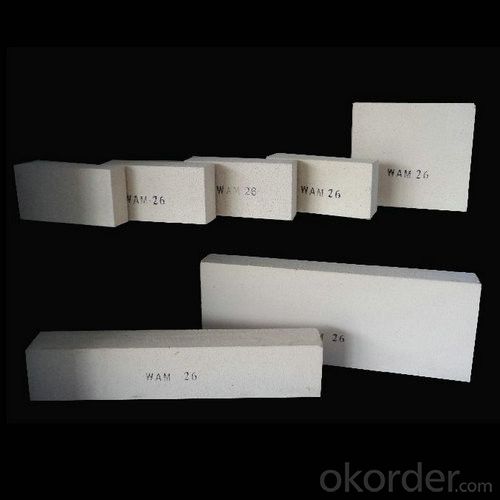

Image of Insulation Fire Brick

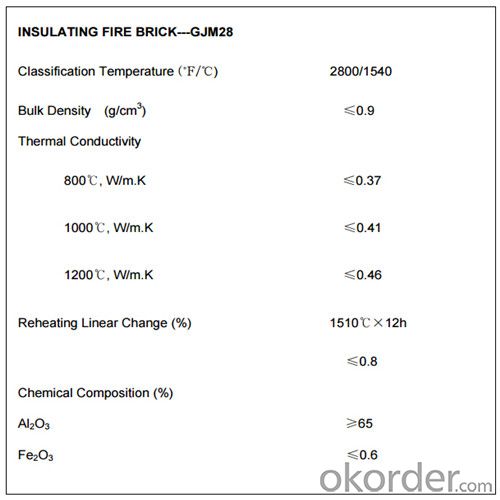

Technical Data of Insulation Firebricks

Feature of Insulation Fire Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulation Fire Brick

CMAX Insulation Fire Brick can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Can insulating fire bricks be used in cryogenic applications?

- Insulating fire bricks, also known as refractory bricks, serve primarily for high-temperature purposes and find common usage in furnaces and kilns. Nonetheless, when it comes to cryogenic applications involving extremely low temperatures, insulating fire bricks may prove to be unsuitable. Cryogenic temperatures, usually below -150 degrees Celsius (-238 degrees Fahrenheit), present distinctive challenges for materials due to the severe thermal stresses they endure. Insulating fire bricks typically consist of materials like alumina and silica, which possess limited resistance to thermal shock and can become brittle at exceedingly low temperatures. This brittleness exposes them to the risk of cracking and failure under cryogenic conditions. Furthermore, insulating fire bricks exhibit relatively high thermal conductivity, implying that they conduct heat rather efficiently. In cryogenic applications, where minimizing heat transfer is of utmost importance, materials with lower thermal conductivity are preferred. Consequently, insulating fire bricks, with their higher thermal conductivity, may not be the most effective choice for cryogenic applications. Instead, materials with exceptional thermal insulation properties and low thermal conductivity, like aerogels or foams made from silica or carbon, are often favored for cryogenic applications. These materials offer superior thermal insulation and better resistance to extreme temperatures, ensuring efficient and dependable performance in cryogenic environments. In conclusion, while insulating fire bricks find suitability in high-temperature applications, they may not be the optimal selection for cryogenic applications due to their brittleness at low temperatures and relatively high thermal conductivity. Materials specifically designed for cryogenic conditions, such as aerogels or foams, prove to be more suitable for these extreme temperature environments.

- Q: What are the main components of insulating fire bricks?

- The main components of insulating fire bricks are refractory materials, such as aluminum oxide or silica, and various additives that enhance their insulation properties, such as organic fibers or lightweight aggregates.

- Q: Can insulating fire bricks be used in chimneys and flues?

- Insulating fire bricks are specifically designed for high-temperature applications and are often used in furnaces, kilns, and other industrial settings. While they do possess excellent insulating properties, they may not be the best choice for chimneys and flues in residential or commercial buildings. The main reason for this is that insulating fire bricks are not as durable and heat-resistant as other materials specifically designed for chimney and flue construction. They may crack or break when exposed to the extreme heat and rapid temperature changes that occur in chimneys. Additionally, these bricks are not typically designed to withstand the corrosive effects of flue gases, which can lead to their degradation over time. When it comes to chimneys and flues, it is generally recommended to use materials such as clay flue liners, stainless steel, or refractory bricks that are specifically manufactured for these applications. These materials are better suited to handle the high temperatures, corrosive gases, and rapid thermal expansion and contraction that occur in chimneys. It is important to consult with a professional chimney or flue specialist who can advise on the appropriate materials to use based on the specific requirements and conditions of your chimney or flue system.

- Q: Can insulating fire bricks be used in fireplace construction?

- Indeed, fireplace construction can make use of insulating fire bricks. These bricks are specifically crafted to endure extreme temperatures and offer exceptional insulation, rendering them appropriate for lining fireplaces. By retaining heat and impeding heat transfer to the surrounding structure, they enhance the fireplace's efficiency while diminishing the likelihood of harm to adjacent materials. Moreover, the lightweight and manageable nature of insulating fire bricks make them an excellent choice for constructing fireplaces.

- Q: Can insulating fire bricks be used in cement plants?

- Yes, insulating fire bricks can be used in cement plants. Insulating fire bricks are designed to withstand high temperatures and are commonly used in industries that require thermal insulation. In cement plants, they can be used in various applications such as lining kilns, furnaces, and other high-temperature equipment. These bricks help in reducing heat loss, improving energy efficiency, and ensuring consistent and controlled temperatures in the cement production process. Additionally, insulating fire bricks are lightweight and have low thermal conductivity, making them an ideal choice for insulating applications in cement plants.

- Q: Can insulating fire bricks be used for insulation in gas furnaces?

- Yes, insulating fire bricks can be used for insulation in gas furnaces. They are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in gas furnaces to improve energy efficiency and enhance overall performance.

- Q: Can insulating fire bricks be used for both residential and commercial purposes?

- Yes, insulating fire bricks can be used for both residential and commercial purposes. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for various applications such as lining fireplaces, kilns, furnaces, and industrial ovens in both residential and commercial settings.

- Q: Are insulating fire bricks resistant to acids and alkalis?

- The resistance of insulating fire bricks to acids and alkalis may vary depending on their composition and manufacturing process. Typically, these bricks are made from materials like alumina, silica, or a combination of both, which offer excellent resistance to high temperatures and thermal conductivity. Moreover, these materials are chemically inert, meaning they do not react with acids or alkalis. Nevertheless, it is important to acknowledge that certain acids and alkalis can still cause slight degradation or corrosion over time, particularly if they are highly concentrated or used at elevated temperatures. Therefore, it is advisable to refer to the manufacturer's specifications or conduct specific tests to determine the bricks' resistance level to particular acids or alkalis. In conclusion, insulating fire bricks are suitable for applications involving exposure to acids and alkalis. However, it is always recommended to consider the specific requirements and consult experts or manufacturers to ensure that the bricks will perform adequately in the intended environment.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Can insulating fire bricks be used in wastewater treatment plants?

- Indeed, insulating fire bricks have the capability to be utilized within wastewater treatment plants. Specifically engineered to endure extreme temperatures, insulating fire bricks are fitting for a variety of industrial applications, including wastewater treatment plants. They are commonly implemented in constructing kilns, furnaces, and other equipment that operates at high temperatures. Within wastewater treatment plants, insulating fire bricks can be incorporated into the assembly of incinerators, thermal oxidizers, and other systems that necessitate high-temperature insulation. Their exceptional properties, such as remarkable thermal resistance, minimal thermal conductivity, and exceptional insulation abilities, make them an ideal choice for maintaining the desired temperatures in these systems while simultaneously diminishing heat loss. Moreover, insulating fire bricks demonstrate resistance to chemical attacks, a vital characteristic within wastewater treatment plants that handle a plethora of chemicals and corrosive substances. In summary, the utilization of insulating fire bricks in wastewater treatment plants can lead to enhanced energy efficiency, reduced maintenance expenses, and the assurance of longevity for high-temperature equipment.

Send your message to us

High-Temperature Insulating Fire Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords