Insulating Fire Brick - GJM26 High Temperature Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What it the Insulating Fire Brick?

Insulating fire bricks (IFBs) are called soft bricks comparing to hard bricks or Fireclay bricks and they are light in weight. Insulating fire brick can be easily cut by handheld hack saw or other hand tools like chisel. Insulating firebricks have high porous rate and have excellent insulating properties.

What are the applications of Insulating Fire Brick?

Glass Industries

Ceramics Industries

Electrolytic Aluminum Industries

Iron & Steel Industries

Non-Ferrous Metals Industries

Power Generation Industries

Primary hot surface linings

Sulphur recovery equipment

Cracking Furnace; Conversion Furnace

Heating equipment or Heating Furnace, Even-heating Furnace, Heat-processing Furnace

What are the excellent features of Insulating Fire Brick?

High heat resistance and durability

Excellent insulating properties

Excellent resistance to thermal shock

Low thermal conductivity

Low heat storage

Excellent construction/compressive strength

Particularly suited to highest temperature applications above 1600°C or 2800°F

Structural integrity capable of dealing with erosive and abrasive environments

Low impurity

Precise dimensions

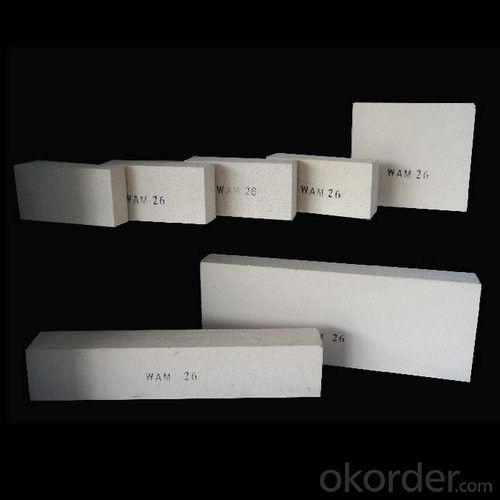

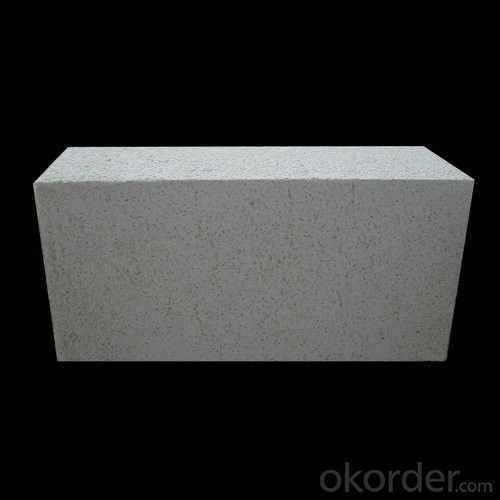

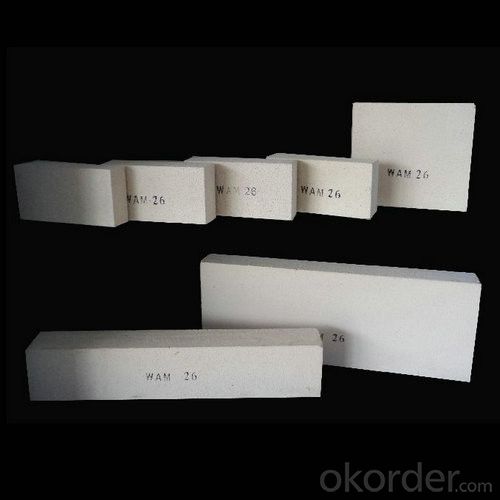

Image of Insulating Fire Brick

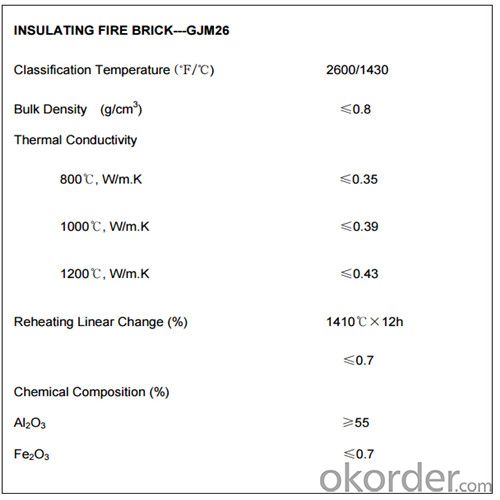

Technical Data of Insulating Fire Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Can insulating fire bricks be used in low-temperature applications as well?

- Yes, insulating fire bricks can be used in low-temperature applications. Insulating fire bricks are designed to have high thermal insulation properties, which means they can effectively prevent heat transfer. This makes them suitable for use in both high-temperature and low-temperature environments. In low-temperature applications, insulating fire bricks can help to minimize heat loss and maintain a stable temperature. They can be used to insulate walls, floors, and roofs of structures or equipment that require temperature control, such as cold storage facilities, refrigerators, or freezers. Insulating fire bricks are also commonly used in low-temperature furnaces and kilns, where they help to minimize energy consumption and maintain a consistent temperature throughout the heating process. Their high insulating properties ensure that the heat generated inside the furnace or kiln is effectively contained, reducing heat loss and improving overall energy efficiency. Furthermore, insulating fire bricks are lightweight and easy to handle, making them convenient for various low-temperature applications. They are also resistant to thermal shock and offer excellent structural stability, ensuring long-lasting performance even in challenging environments. Overall, insulating fire bricks can be effectively utilized in low-temperature applications to enhance energy efficiency, temperature control, and structural stability.

- Q: Can insulating fire bricks be used in refractory lining for steelmaking?

- Insulating fire bricks can indeed be utilized for refractory lining in the steelmaking industry. Crafted from lightweight ceramic materials, these bricks possess remarkable thermal insulation properties. Consequently, they prove to be highly suitable for applications involving elevated temperatures, such as steelmaking, where the maintenance of a consistent temperature is of utmost importance. By incorporating insulating fire bricks, heat loss can be minimized, energy efficiency can be enhanced, and insulation against the extreme temperatures encountered in steel production can be provided. Moreover, these bricks exhibit resistance to thermal shock, a vital characteristic for withstanding sudden temperature fluctuations during the steelmaking process. Consequently, the utilization of insulating fire bricks within refractory lining for steelmaking purposes can significantly optimize the performance and efficiency of the entire steelmaking operation.

- Q: Are insulating fire bricks resistant to thermal fatigue?

- Insulating fire bricks exhibit remarkable resistance to thermal fatigue. These bricks are purposefully engineered to endure elevated temperatures and thermal cycling without experiencing any cracks or fractures. Composed of refractory materials with exceptional thermal shock resistance, they possess the ability to expand and contract without suffering significant harm. This capacity to withstand thermal fatigue renders insulating fire bricks highly suitable for applications involving extreme temperature fluctuations, such as kilns, furnaces, and other environments with high temperatures.

- Q: How long do insulating fire bricks typically last?

- Insulating fire bricks typically last for several years, with an average lifespan of 10 to 20 years.

- Q: Are insulating fire bricks resistant to oil and gas?

- Insulating fire bricks typically offer resistance against oil and gas. These bricks are crafted from high temperature materials like alumina and silica, which grant exceptional thermal insulation qualities and can endure elevated temperatures. They are commonly employed in industries where exposure to heat occurs, such as furnaces, kilns, and fireplaces. Nevertheless, it is crucial to acknowledge that the resistance to oil and gas can vary depending on the precise composition and manufacturing process of the insulating fire bricks. Certain bricks may exhibit higher resistance to oil and gas compared to others. To guarantee the utmost resistance to oil and gas, it is recommended to utilize insulating fire bricks that are specifically engineered for such applications. These bricks are often known as oil and gas resistant fire bricks and are formulated with supplementary additives or coatings that enhance their resistance to these substances. In conclusion, although insulating fire bricks generally offer resistance to oil and gas, it is advisable to employ bricks that are specifically tailored for such applications to ensure optimal performance and longevity.

- Q: Can insulating fire bricks be used in refractory lining applications?

- Insulating fire bricks can indeed find utility in various refractory lining applications. Crafted from lightweight materials like clay or silica, these bricks possess exceptional insulating properties. Their main purpose is to offer superior thermal insulation, thereby minimizing heat loss and promoting energy efficiency, particularly in high-temperature settings. Commonly adopted in refractory lining applications, insulating fire bricks serve to line the walls, floors, and roofs of furnaces, boilers, kilns, and similar industrial equipment. Their effectiveness lies in their ability to impede heat transfer to the surrounding environment while maintaining the desired internal temperature. In addition, insulating fire bricks exhibit remarkable resistance to thermal shock. This means they can tolerate rapid temperature fluctuations without cracking or failing. Consequently, they prove suitable for applications involving frequent heating and cooling cycles. Moreover, these bricks boast low thermal conductivity. This quality allows them to effectively restrict heat transfer between distinct areas of the refractory lining. Consequently, they play a crucial role in preventing hotspots and temperature imbalances, thereby ensuring the uniform distribution of heat throughout the equipment. Taken as a whole, insulating fire bricks represent a versatile and efficient choice for refractory lining applications. They excel in providing exceptional thermal insulation, resilience against thermal shock, and uniform heat distribution.

- Q: Can insulating fire bricks be used in cement plants?

- Certainly, cement plants can utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and are widely employed in thermal insulation-demanding industries. Within cement plants, they can find diverse applications, including kiln lining, furnace lining, and other equipment operating at high temperatures. These bricks effectively decrease heat dissipation, enhance energy efficiency, and maintain stable and regulated temperatures during cement production. Furthermore, insulating fire bricks possess a lightweight nature and exhibit low thermal conductivity, rendering them an optimal selection for insulation purposes within cement plants.

- Q: What are the insulation materials for heating buried pipelines?

- The thickness of insulation layer should be reasonable and economical. If the insulation layer is too thin, the heat loss will be increased; the insulation layer is too thick, and the surface area of the radiator will be increased, and the heat loss will also be increased. In general the design, determine the thickness of the insulation layer according to the factors of insulation material properties, heat medium temperature, often used for 40~50 mm thickness.

- Q: Do insulating fire bricks have a high thermal stability?

- Yes, insulating fire bricks have a high thermal stability. These bricks are designed to withstand high temperatures without deteriorating or losing their insulating properties. They are made from high-quality refractory materials that can withstand extreme temperatures, making them ideal for applications where thermal stability is crucial. Insulating fire bricks have low thermal conductivity, which means they can effectively trap heat and prevent it from escaping. This property allows them to maintain stable temperatures in environments where heat retention is essential, such as furnaces, kilns, and other high-temperature industrial processes. Overall, insulating fire bricks are known for their excellent thermal stability, making them a reliable choice for applications that require insulation and protection against high temperatures.

- Q: Are insulating fire bricks resistant to alkali vapor attack?

- Yes, insulating fire bricks are generally resistant to alkali vapor attack. They have a high degree of chemical stability and can withstand exposure to alkali vapors without significant degradation or damage.

Send your message to us

Insulating Fire Brick - GJM26 High Temperature Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords