Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Low density.

2. Classification temperature:1610-1780.

3. Thermal insulation energy-saving effect is good.Refractory mullite insulating refractory brick JM 23

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

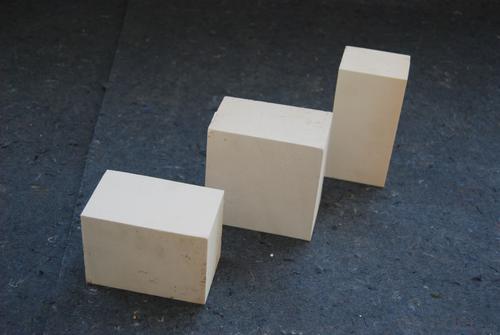

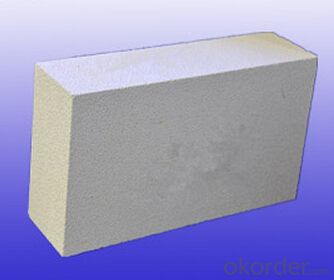

Insulating brick picture

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

High alumina insulation brick,Insulation brick,Fireclay insulation brick

Features:

1. Low thermal conductivity.

2. High strength and resistance to corrosion.

3. Low heat capacity.

4. Low shrinkage after heavy firing.

5. High insulation.

6. High refractoriness.

7. Low density.

8. Good thermal shock resistance under high temperature.

9. Thermal insulation energy-saving effect is good.

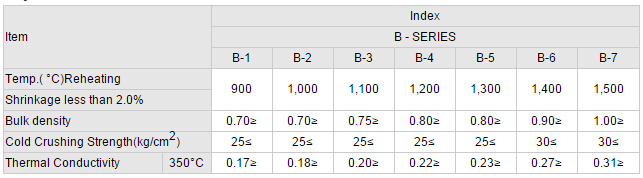

Physical and chemical index:

Application:

Insulation brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.

- Q: Do insulating fire bricks require maintenance?

- Yes, insulating fire bricks require minimal maintenance. They are designed to withstand high temperatures and are resistant to cracking or crumbling. However, regular cleaning to remove any debris or buildup is recommended to maintain their insulating properties and extend their lifespan.

- Q: Can insulating fire bricks be used in the construction of high-temperature reactors?

- Yes, insulating fire bricks can be used in the construction of high-temperature reactors. These bricks are designed to withstand and retain high temperatures, making them suitable for use in applications such as high-temperature reactors where heat insulation is required.

- Q: What is the price of concrete self insulation bricks?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: Can insulating fire bricks be used in the construction of metal smelting molds?

- Yes, insulating fire bricks can be used in the construction of metal smelting molds. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in smelting processes where extreme heat is required. These bricks have excellent thermal insulation properties, which help to retain the heat and minimize heat loss during the smelting process. This is important for maintaining a consistent temperature within the mold, ensuring efficient and successful metal smelting. Additionally, insulating fire bricks are lightweight and easy to handle, making them a practical choice for constructing molds. Overall, insulating fire bricks are a reliable and effective option for constructing metal smelting molds.

- Q: Can insulating fire bricks be used in ceramic kilns?

- Yes, insulating fire bricks can be used in ceramic kilns. These bricks are designed to have high insulating properties, making them ideal for maintaining heat within the kiln. They are lightweight and can withstand high temperatures, making them a suitable choice for ceramic kilns.

- Q: Are insulating fire bricks suitable for use in glass furnaces?

- Indeed, glass furnaces can benefit from the use of insulating fire bricks. The purpose of these bricks is to possess a low thermal conductivity, thereby effectively insulating the soaring temperatures within the furnace. By minimizing heat loss, these bricks ensure a steady temperature is maintained inside the furnace, a vital factor in the glass-making process. Moreover, insulating fire bricks are capable of enduring the intense temperatures and thermal shocks typically experienced in glass furnaces. Additionally, their lightweight nature facilitates simple installation and maintenance procedures. In conclusion, insulating fire bricks prove to be a dependable and pragmatic option for utilization in glass furnaces.

- Q: Can insulating fire bricks be used in chimneys and flues?

- Yes, insulating fire bricks can be used in chimneys and flues. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for use in areas where heat needs to be contained or controlled, such as chimneys and flues.

- Q: Are insulating fire bricks suitable for use in the construction of smelters?

- Insulating fire bricks are indeed appropriate for the construction of smelters. These bricks are specifically engineered to endure high temperatures and offer exceptional insulation qualities, thus rendering them a perfect choice for smelting purposes. Their thermal conductivity is low, enabling efficient heat retention and minimized energy wastage throughout the smelting procedure. Moreover, insulating fire bricks exhibit resistance to thermal shock, a vital feature in smelting operations characterized by abrupt temperature fluctuations. Thus, owing to their superior capacity to withstand heat and insulate, insulating fire bricks present a dependable option for smelter construction.

- Q: Can insulating fire bricks be used in the construction of autoclaves?

- Yes, insulating fire bricks can be used in the construction of autoclaves. Autoclaves require materials that can withstand high temperatures and pressures, and insulating fire bricks are designed to have excellent thermal resistance and insulation properties. These bricks are made from refractory materials like alumina, silica, and other additives that allow them to withstand extreme temperatures and thermal shocks. They are also lightweight and have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in autoclaves. Additionally, insulating fire bricks have good load-bearing capacity, making them suitable for the structural components of autoclaves. Overall, the use of insulating fire bricks in the construction of autoclaves helps to ensure the safety and efficiency of the equipment.

- Q: What is the lifespan of insulating fire bricks?

- The lifespan of insulating fire bricks can vary depending on several factors. Typically, these bricks are designed to have a long lifespan and can last for several years or even decades if properly installed and maintained. The quality of the insulating fire bricks plays a significant role in determining their lifespan. High-quality bricks that are manufactured using superior materials and manufacturing processes tend to have a longer lifespan compared to lower-quality bricks. It is essential to choose bricks from reputable manufacturers that adhere to strict quality control standards. Another critical factor is the application and conditions in which the insulating fire bricks are used. If the bricks are exposed to extreme temperatures, such as in furnaces or kilns, they may experience thermal shock and degradation over time. Similarly, exposure to corrosive chemicals or abrasive materials can also impact the lifespan of the bricks. Proper installation and maintenance are crucial for maximizing the lifespan of insulating fire bricks. They should be installed according to the manufacturer's guidelines, ensuring that they are properly aligned and supported. Regular inspections should be conducted to identify any signs of damage or wear, and immediate repairs or replacements should be made as needed. Overall, while the specific lifespan of insulating fire bricks cannot be determined with absolute certainty, it is reasonable to expect them to last for several years to several decades when used in appropriate applications and maintained properly.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords