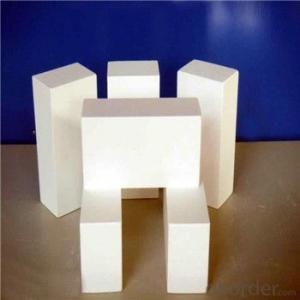

High Temperature Refractory High Density Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How do insulating fire bricks prevent heat transfer?

- Combining both their composition and structure, insulating fire bricks prevent the transfer of heat. These bricks are crafted from specialized refractory materials, such as silica, alumina, or clay, which possess high thermal resistance. Essentially, these materials have low thermal conductivity, meaning they are not easily able to conduct heat. Moreover, insulating fire bricks are often manufactured with tiny air pockets or cells within their structure. These air pockets serve as barriers for heat transfer since air is a poor conductor of heat. Consequently, when heat is applied to one side of the brick, the refractory materials' low thermal conductivity, coupled with the presence of air pockets, collaboratively minimize the amount of heat conducted through the brick. Consequently, this effectively prevents heat from transferring from one side of the brick to the other, providing insulation and reducing energy loss.

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Insulating fire bricks are not suitable for use in coke ovens. Coke ovens require bricks that can withstand extremely high temperatures and harsh chemical environments. Insulating fire bricks are designed to provide thermal insulation and are not able to withstand the heat and chemical exposure that occurs in coke ovens. Therefore, it is crucial to use refractory bricks specifically designed for coke ovens, which have high resistance to temperature, chemical attacks, and thermal shock. These refractory bricks are typically made from materials such as silica, alumina, and carbon, which can withstand the harsh conditions inside the coke ovens.

- Q: Are insulating fire bricks suitable for use in steel manufacturing plants?

- Yes, insulating fire bricks are suitable for use in steel manufacturing plants. Insulating fire bricks have excellent thermal properties, including high heat resistance and low thermal conductivity, which make them ideal for use in high-temperature environments such as steel manufacturing plants. These bricks can withstand the extreme heat generated during steel production processes, such as melting, casting, and forging. Additionally, insulating fire bricks help to conserve energy by reducing heat loss, thus improving the overall efficiency of the plant. They also have good mechanical strength and can withstand the physical stresses and strains associated with steel manufacturing operations. Overall, the use of insulating fire bricks in steel manufacturing plants can help to enhance safety, increase productivity, and improve energy efficiency.

- Q: Can insulating fire bricks be used in the construction of thermal insulation walls?

- Yes, insulating fire bricks can be used in the construction of thermal insulation walls. Insulating fire bricks are specially designed bricks that have a low thermal conductivity, which means they are excellent at preventing the transfer of heat. This makes them ideal for use in thermal insulation applications. When constructing thermal insulation walls, insulating fire bricks can be used as the primary material or in conjunction with other insulation materials such as foam boards or mineral wool. These bricks are typically lightweight, which makes them easier to handle and install. They also have high temperature resistance, allowing them to withstand the heat generated by fireplaces, ovens, or other heat-producing appliances. Insulating fire bricks offer several benefits for thermal insulation walls. They help to minimize heat loss or gain, thereby improving energy efficiency in buildings. They also help to reduce noise transmission, making them suitable for soundproofing applications. It is important to note that insulating fire bricks may not be suitable for all types of walls or building structures. Factors such as building codes, environmental conditions, and specific requirements of the project should be considered when determining if insulating fire bricks are the appropriate choice for thermal insulation walls. Consulting with a professional architect or engineer is recommended to ensure the best insulation solution for a specific construction project.

- Q: Are insulating fire bricks resistant to high-velocity gas flow erosion?

- Yes, insulating fire bricks are generally resistant to high-velocity gas flow erosion. These bricks are specifically designed to withstand extreme temperatures and harsh conditions, including erosive environments. They are made from high-quality refractory materials, such as alumina and silica, which have excellent resistance to erosion and corrosion. Additionally, insulating fire bricks have a low thermal conductivity, which helps to reduce heat loss and maintain their structural integrity even under high-velocity gas flow. However, it is important to note that the exact resistance may vary depending on the specific composition and manufacturing process of the insulating fire bricks.

- Q: How do insulating fire bricks affect the overall sustainability of a structure?

- Insulating fire bricks play a crucial role in enhancing the overall sustainability of a structure. These bricks are designed to have low thermal conductivity, which helps in minimizing heat loss from the building. By providing effective insulation, they contribute to energy efficiency by reducing the need for excessive heating or cooling. This, in turn, leads to lower energy consumption and reduced carbon emissions, making the structure more environmentally friendly. Furthermore, insulating fire bricks have excellent durability, enabling them to withstand high temperatures and extreme conditions, resulting in longer-lasting structures that require fewer repairs and replacements. Overall, insulating fire bricks enhance the sustainability of a structure by improving energy efficiency and durability, leading to reduced environmental impact and long-term cost savings.

- Q: Can insulating fire bricks be used for insulation in steam pipes?

- Yes, insulating fire bricks can be used for insulation in steam pipes. They are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for this application.

- Q: What are the sizes of lightweight thermal insulation bricks?

- The production of material ordinary lightweight insulating refractory brick with fireclay and high alumina high strength bead brick

- Q: How do insulating fire bricks affect the overall noise reduction of a structure?

- Insulating fire bricks play a crucial role in reducing the overall noise levels within a structure. These bricks are specifically designed to have excellent sound absorption properties, making them highly effective in reducing noise transmission. The high-density and low-porosity nature of insulating fire bricks allows them to absorb and dampen sound waves effectively. When sound waves pass through the bricks, the energy of the waves is converted into heat due to the internal friction of the material. This conversion process helps to minimize the transmission of sound, resulting in a quieter environment. Additionally, insulating fire bricks are known for their thermal insulation properties, which indirectly contribute to noise reduction. These bricks help in maintaining a stable temperature within the structure, preventing the expansion and contraction of materials that can generate unwanted noise. It is worth mentioning that the impact of insulating fire bricks on noise reduction may vary depending on the specific construction and design of the structure. The thickness and placement of the bricks, as well as the presence of other sound-absorbing materials, should be considered to achieve the desired level of noise reduction. In summary, insulating fire bricks significantly contribute to the overall noise reduction of a structure by absorbing and dampening sound waves. Their ability to convert sound energy into heat, along with their thermal insulation properties, makes them an effective solution for creating a quieter environment.

- Q: Do insulating fire bricks have a high thermal stability?

- Yes, insulating fire bricks have a high thermal stability. These bricks are designed to withstand high temperatures without deteriorating or losing their insulating properties. They are made from high-quality refractory materials that can withstand extreme temperatures, making them ideal for applications where thermal stability is crucial. Insulating fire bricks have low thermal conductivity, which means they can effectively trap heat and prevent it from escaping. This property allows them to maintain stable temperatures in environments where heat retention is essential, such as furnaces, kilns, and other high-temperature industrial processes. Overall, insulating fire bricks are known for their excellent thermal stability, making them a reliable choice for applications that require insulation and protection against high temperatures.

Send your message to us

High Temperature Refractory High Density Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords