Insulating Refractory Bricks High-Alumina Brick for Furnace Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

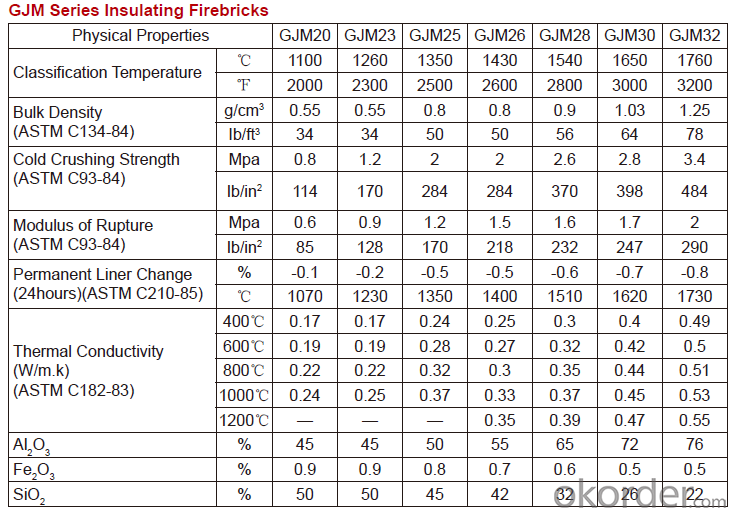

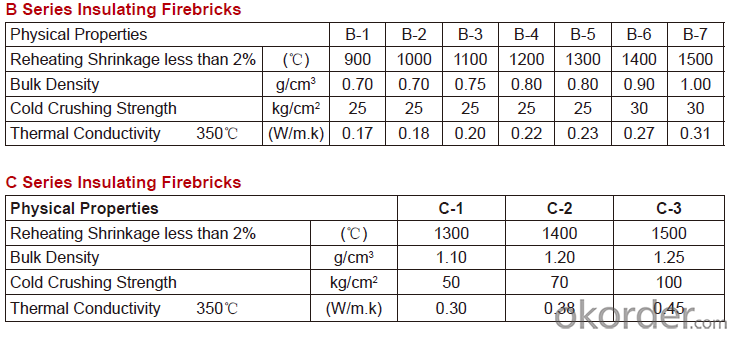

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used as insulation in walls and roofs?

- Yes, insulating fire bricks can be used as insulation in walls and roofs. They have excellent thermal insulation properties, high heat resistance, and are specifically designed for use in high-temperature environments.

- Q: Can insulating fire bricks be used in the construction of high-temperature reactors?

- Indeed, high-temperature reactors can incorporate insulating fire bricks in their construction. These bricks are explicitly engineered to endure elevated temperatures, rendering them apt for deployment in high-temperature settings like reactors. Their exceptional thermal insulation qualities contribute to minimizing heat loss and upholding the desired temperature within the reactor. Moreover, insulating fire bricks boast remarkable refractoriness, enabling them to endure intense heat without substantial distortion or harm. Hence, they represent an optimal selection for the construction of high-temperature reactors, wherein maintaining a steady and regulated temperature is vital for the reactor's effective operation.

- Q: Are insulating fire bricks resistant to molten salts?

- Yes, insulating fire bricks are generally resistant to molten salts. These bricks are specifically designed to withstand high temperatures and offer excellent thermal insulation. They are often made from special refractory materials that have a high melting point and are chemically inert. Molten salts, on the other hand, are highly corrosive and can cause damage to many materials. However, insulating fire bricks are able to withstand the corrosive nature of molten salts due to their unique composition. Their dense structure and high refractory properties allow them to resist the corrosive effects of molten salts for prolonged periods. Furthermore, insulating fire bricks are often used in industries such as metal smelting, glass manufacturing, and chemical processing, where molten salts are commonly encountered. Their resistance to molten salts makes them ideal for applications involving these corrosive substances. However, it is important to note that the exact resistance of insulating fire bricks to molten salts can vary depending on the specific composition of the brick and the type of molten salt being used. Therefore, it is recommended to consult with the manufacturer or a specialist in refractory materials to ensure the suitability of insulating fire bricks for a particular application involving molten salts.

- Q: Can insulating fire bricks be used in chimneys?

- Insulating fire bricks are indeed suitable for chimneys. Their purpose lies in enduring high temperatures, rendering them an excellent option for lining chimneys. Not only do they possess superb thermal insulation properties, thus minimizing heat loss and enhancing chimney efficiency, but they are also lightweight and simple to install. Nonetheless, it is crucial to acknowledge that insulating fire bricks may not be suitable for every chimney type. To ascertain the appropriate materials for your individual chimney requirements, consulting a professional or chimney specialist is highly recommended.

- Q: Can insulating fire bricks be used in the construction of gas kilns?

- Yes, insulating fire bricks can be used in the construction of gas kilns. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for gas kilns where heat retention is crucial.

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Yes, insulating fire bricks are suitable for use in coke ovens. These bricks are designed to withstand high temperatures and provide excellent insulation properties, making them ideal for use in coke ovens where extreme heat is generated during the coking process. They help to maintain the desired temperature inside the oven and prevent heat loss, resulting in improved energy efficiency and reduced fuel consumption. Additionally, insulating fire bricks have good resistance to chemical reactions and thermal shock, which further enhances their suitability for use in coke ovens.

- Q: Are insulating fire bricks resistant to fire damage?

- Yes, insulating fire bricks are specifically designed to be resistant to fire damage. They are made from special refractory materials that can withstand extremely high temperatures without deforming or losing their insulating properties. Insulating fire bricks have a high melting point and low thermal conductivity, which allows them to effectively insulate against heat transfer and protect against fire damage. They are commonly used in applications where high temperatures and fire exposure are expected, such as in furnaces, kilns, fireplaces, and industrial processes. Overall, insulating fire bricks are reliable and durable materials that provide excellent protection against fire damage.

- Q: Can insulating fire bricks be used for insulation in smelting furnaces?

- Yes, insulating fire bricks can be used for insulation in smelting furnaces. They are designed to withstand high temperatures and provide excellent thermal insulation, making them an ideal choice for smelting furnace insulation to minimize heat loss and improve energy efficiency.

- Q: Can insulating fire bricks be used for insulation in autoclaves?

- Yes, insulating fire bricks can be used for insulation in autoclaves. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain heat and withstand high temperatures. Autoclaves require insulation to maintain a consistent temperature and pressure, and insulating fire bricks can provide excellent insulation properties in these demanding conditions. Additionally, their high strength and durability make them suitable for withstanding the intense heat and pressure cycles that occur in autoclaves. Overall, insulating fire bricks are a reliable and effective choice for insulating autoclaves.

- Q: Are insulating fire bricks resistant to moisture or water damage?

- Yes, insulating fire bricks are resistant to moisture or water damage. They are designed to withstand high temperatures and do not absorb water, making them a suitable choice for applications where moisture or water exposure is a concern.

Send your message to us

Insulating Refractory Bricks High-Alumina Brick for Furnace Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords