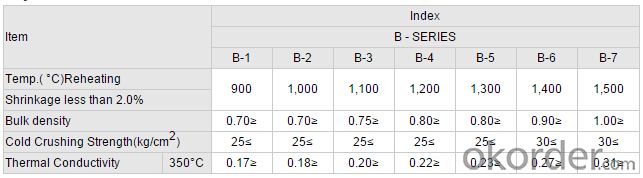

Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Mullite Insulating Fire Brick JM 23

OKORDER Series Insulating Bricks

OKORDER series insulating bricks are a kind of highly efficient, energy saving, low-carbon, environmental protection advanced products which are manufactured according to ASTM standard. OKORDER series products are the best lining and insulation materials in all types of industrial furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass. They can be applied as heat insulation or no-melt erosion parts of the working layer. The products have been widely used in the following furnaces and achieved satisfactory results.

Application of Insulating Bricks

Metallurgy industry: Blast furnace, Hot blast stove, Reheating furnace, etc.

Petrochemical industry: Ethylene cracking furnace, Hydrogen production furnace, Primary reformer furnace, Reheating furnace, etc.

Ceramics Industry: Roller kiln, Pusher kiln, etc.

Glass industry: Glass furnace regenerator, etc.

Carbon Industry: Carbon roaster, etc.

Aluminum electrolytic industry: aluminum reduction cells,etc.

Other industries: Tunnel kiln, Shuttle kiln, etc.

Advantages of Insulating Bricks

Low Thermal Conductivity: More porosity brings excellent insulation effect, energy saving.

High Crushing Strength: High crushing strength under thermal state, volume stability.

Low Heat Storage: Little thermal storage when absorb more heat, energy saving effect is obvious.

High Purity: Low content of iron, alkaline and metal impurities.

Accurate Dimension: Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

Application:

Insulation brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.

- Q: Can insulating fire bricks be used in solar power plants?

- Yes, insulating fire bricks can be used in solar power plants. Insulating fire bricks are designed to have excellent thermal insulation properties, making them suitable for applications that require heat resistance and energy efficiency. Solar power plants often involve high temperatures and the need to retain heat, such as in concentrated solar power (CSP) systems. Insulating fire bricks can be used to line the walls and floors of CSP receivers and thermal storage systems, helping to minimize heat loss and maximize the conversion of solar energy into electricity. Additionally, insulating fire bricks can also be used in other components of solar power plants, such as in the insulation of solar panels or in the construction of solar tower structures.

- Q: Are insulating fire bricks resistant to acid attack?

- Yes, insulating fire bricks are generally resistant to acid attack. Insulating fire bricks are made from materials that can withstand high temperatures and are designed to provide excellent insulation properties. These bricks are typically made from lightweight refractory materials such as alumina, silica, and other refractory oxides. These materials are known for their resistance to chemical corrosion, including acids. However, it is important to note that the resistance of insulating fire bricks to acid attack can vary depending on the specific composition and manufacturing process of the bricks. Some bricks may have higher resistance to acids compared to others. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the acid resistance of their insulating fire bricks. In general, insulating fire bricks are commonly used in applications where they may come into contact with acids, such as in industrial furnaces, kilns, and other high-temperature environments. They are known for their durability and ability to withstand harsh chemical environments, including exposure to acids. However, it is always important to consider the specific chemical composition and concentration of the acids involved, as well as the temperature conditions, when determining the suitability of insulating fire bricks for a particular application.

- Q: Can insulating fire bricks be installed in both industrial and residential settings?

- Insulating fire bricks can be utilized in both industrial and residential environments. These bricks are specifically engineered to endure extreme temperatures and offer superb insulation, rendering them appropriate for various purposes. In industrial settings, insulating fire bricks are frequently employed in furnaces, kilns, and ovens, as they aid in conserving energy and ensuring stable temperatures. In residential settings, they can be employed in fireplaces, wood-burning stoves, and pizza ovens, enhancing heat retention and promoting safety. Due to their versatility and durability, insulating fire bricks are a dependable option for installations in both industrial and residential settings.

- Q: Can insulating fire bricks be used in metal melting furnaces?

- Yes, insulating fire bricks can be used in metal melting furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them an ideal choice for applications like metal melting furnaces. These bricks have low thermal conductivity, which helps to retain heat and reduce energy consumption. Additionally, insulating fire bricks are lightweight, durable, and resistant to thermal shock, making them suitable for the extreme conditions encountered in metal melting furnaces.

- Q: Can insulating fire bricks be used to build pizza ovens?

- Yes, insulating fire bricks can be used to build pizza ovens. Insulating fire bricks are known for their high heat resistance and low thermal conductivity, making them a suitable material for constructing pizza ovens that require high temperatures for efficient cooking. These bricks can help retain heat and distribute it evenly, resulting in a well-insulated and efficient pizza oven.

- Q: Can insulating fire bricks be used in copper smelting furnaces?

- Yes, insulating fire bricks can be used in copper smelting furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in furnaces. They are made from materials that can handle the extreme heat generated during the smelting process and can effectively retain and reflect heat back into the furnace. This helps to maintain the desired temperature and improve energy efficiency. Additionally, insulating fire bricks can help to reduce heat loss, resulting in faster and more efficient copper smelting. Therefore, using insulating fire bricks in copper smelting furnaces is a common practice in the industry.

- Q: Are insulating fire bricks resistant to vermin infestation?

- Despite their excellent insulation properties and widespread usage in high-temperature applications like fireplaces or kilns, insulating fire bricks are not specifically engineered to resist vermin infestation. It should be noted that vermin, including rats or mice, can still infiltrate the minute gaps or crevices present between these bricks. Furthermore, if the bricks are composed of softer materials like ceramic fiber or lightweight refractory materials, vermin can even gnaw through them. To effectively prevent vermin infestation, it is crucial to implement additional measures such as using appropriate sealants or mortar to seal any gaps or cracks between the bricks. Furthermore, conducting regular inspections and maintenance is highly recommended to promptly identify and address any indications of vermin activity.

- Q: There are several construction techniques for exterior wall insulation

- Exterior wall sandwich insulation technologyThe exterior wall sandwich insulation is to place the heat preservation material between the inner and outer wall sheets of the outer wall, and the inner and outer walls can be made of concrete hollow blocks.Advantage:1) to the inner wall piece and the heat preservation material forms the effective protection, to the heat preservation material selection material request is not high (source: Chinese heat preservation net), polystyrene, glass cotton and urea aldehyde field casting material and so on may use;2) the construction season and construction conditions are not very high, and it does not affect the winter construction. In Heilongjiang, Inner Mongolia, northern Gansu and other cold areas have been given some applications.Shortcoming:1) in non cold areas, this kind of wall is thicker than traditional wall;2) the inner and the outer wall pieces need to be connected by connecting pieces, and the structure is more complicated than the traditional wall;3) periphery structure of "bridge" more. In the earthquake zone, building circle beam and constructional column settings, "bridge" more efficiency of thermal insulation materials is still not fully play.4) outside the walls by the outdoor climate, the temperature difference between day and night and the large temperature difference between summer and winter, easy to cause the wall cracking and leakage of rainwater.

- Q: Are insulating fire bricks resistant to oil or chemical spills?

- Yes, insulating fire bricks are resistant to oil or chemical spills. These bricks are designed to withstand high temperatures and are made from materials that are chemically inert, which makes them highly resistant to the corrosive effects of oil or chemicals. This property makes insulating fire bricks an excellent choice for applications where exposure to oil or chemical spills is expected.

- Q: Are insulating fire bricks suitable for use in the construction of smelters?

- Yes, insulating fire bricks are suitable for use in the construction of smelters. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties, making them ideal for applications such as smelters. They have low thermal conductivity, meaning they can effectively retain heat and reduce energy loss during the smelting process. Additionally, insulating fire bricks are resistant to thermal shock, which is crucial in smelting operations where rapid temperature changes are common. Their high heat resistance and insulation capabilities make insulating fire bricks a reliable choice for constructing smelters.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords