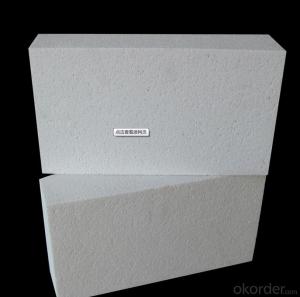

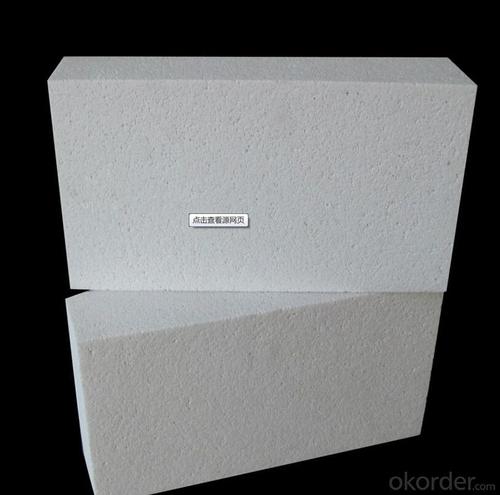

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-5

Light weight mullite insulation furnace bricks refractory for sale

Advantage

Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy savingRefractory GJM Mullite Insulation Brick B-5

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

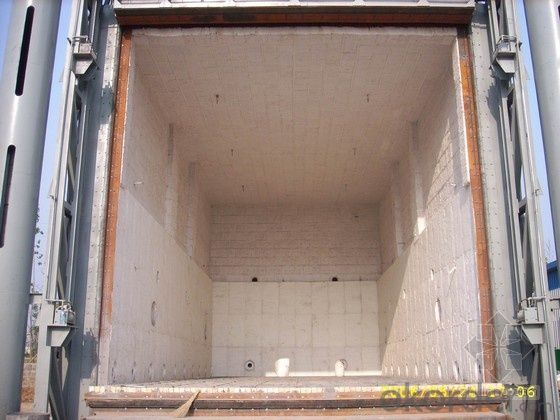

Application:Refractory GJM Mullite Insulation Brick B-5

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-5

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very muchRefractory GJM Mullite Insulation Brick B-5

- Q: Refractory bricks, burner bricks, insulation bricks? Is it a kind of thing?

- The burner brick is heavy brick, the use temperature is higher, the insulating brick is light brick, the use temperature is lower than the heavy brick.

- Q: Can insulating fire bricks be used to build pizza ovens?

- Yes, insulating fire bricks can be used to build pizza ovens. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them a suitable choice for constructing pizza ovens. These bricks have low thermal conductivity, which helps retain and distribute heat evenly throughout the oven. The insulating properties of the bricks help the oven reach and maintain the desired temperature, allowing for efficient and consistent cooking of pizzas. Additionally, insulating fire bricks are lightweight, making them easier to handle and install during the construction process. Overall, insulating fire bricks are a great option for building pizza ovens due to their ability to withstand high temperatures and provide effective insulation.

- Q: Can insulating fire bricks be used in thermal power plants?

- Yes, insulating fire bricks can be used in thermal power plants. Insulating fire bricks are designed to provide thermal insulation and resist high temperatures, making them suitable for applications in thermal power plants. These bricks can be used in various areas of a power plant, such as in the lining of boilers, furnaces, and kilns, where they help to reduce heat loss and increase the overall energy efficiency of the plant. Additionally, insulating fire bricks are lightweight and have good thermal shock resistance, allowing them to withstand the extreme temperature fluctuations that occur in power plant operations.

- Q: Are insulating fire bricks resistant to fire?

- Yes, insulating fire bricks are specifically designed to be highly resistant to fire. They have excellent insulating properties and can withstand high temperatures without cracking or breaking down.

- Q: Can insulating fire bricks be used to build pizza ovens?

- Yes, insulating fire bricks can be used to build pizza ovens. Insulating fire bricks are known for their high heat resistance and low thermal conductivity, making them a suitable material for constructing pizza ovens that require high temperatures for efficient cooking. These bricks can help retain heat and distribute it evenly, resulting in a well-insulated and efficient pizza oven.

- Q: Can insulating fire bricks be used in cement kilns?

- Indeed, in cement kilns, insulating fire bricks find their utility. These bricks are specifically engineered with a low thermal conductivity, rendering them an excellent choice for insulating environments that endure high temperatures, like cement kilns. By employing these bricks, heat loss can be minimized, thereby enhancing energy efficiency within the kiln. Furthermore, their lightweight composition facilitates ease of handling and installation in the kiln. Nevertheless, it is crucial to carefully select insulating fire bricks that align with the unique operating conditions and demands of the cement kiln to guarantee utmost performance and durability.

- Q: Can insulating fire bricks be used in the construction of combustion chambers for rocket engines?

- Yes, insulating fire bricks can be used in the construction of combustion chambers for rocket engines. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. This makes them ideal for applications where extreme heat is involved, such as the combustion chambers of rocket engines. The primary purpose of insulating fire bricks in a rocket engine's combustion chamber is to protect the surrounding structure from the intense heat generated during combustion. By providing insulation, these bricks help to minimize heat transfer to the outer walls of the combustion chamber, preventing damage and ensuring structural integrity. Furthermore, insulating fire bricks are lightweight and have low thermal conductivity, allowing them to effectively retain heat within the combustion chamber. This is crucial for maintaining high combustion efficiency and optimizing rocket performance. In addition to their thermal properties, insulating fire bricks are also known for their durability and resistance to thermal shock. This is particularly important in rocket engine applications where rapid temperature changes can occur, such as during ignition or shutdown sequences. The ability of insulating fire bricks to withstand such thermal stresses is essential for the reliability and longevity of the combustion chamber. Overall, insulating fire bricks are a suitable choice for the construction of combustion chambers in rocket engines due to their high-temperature resistance, thermal insulation capabilities, lightweight nature, and durability.

- Q: Are insulating fire bricks resistant to thermal radiation?

- Yes, insulating fire bricks are designed to be resistant to thermal radiation. These bricks are made from materials that have low thermal conductivity and high thermal resistance, allowing them to effectively insulate against heat transfer through radiation.

- Q: Can insulating fire bricks be used in the construction of coke ovens?

- The use of insulating fire bricks in the construction of coke ovens is indeed possible. These bricks are specifically designed to endure extreme temperatures and offer exceptional thermal insulation. Coke ovens, which typically operate at around 2000 degrees Fahrenheit, necessitate materials that can withstand such conditions. The low thermal conductivity of insulating fire bricks effectively hinders heat transfer between the interior and exterior of the oven. This feature helps to maintain the necessary high temperatures for coal carbonization in the coke oven, while simultaneously minimizing heat loss. Moreover, insulating fire bricks possess a lightweight composition and high strength, which makes them ideal for coke oven construction. Their lightweight nature facilitates easier installation and reduces the overall weight of the structure. Additionally, their high strength ensures that they can endure the harsh operating conditions of the coke oven without cracking or crumbling. In conclusion, insulating fire bricks are a suitable choice for constructing coke ovens due to their ability to withstand high temperatures, provide thermal insulation, and offer durability.

- Q: Are insulating fire bricks resistant to electrical conductivity?

- Yes, insulating fire bricks are resistant to electrical conductivity. These bricks are made from materials that have low electrical conductivity, such as ceramic fibers or insulating refractory materials. The main purpose of insulating fire bricks is to provide thermal insulation, making them ideal for applications where high temperatures need to be contained. As a result of their low electrical conductivity, insulating fire bricks do not conduct electricity and are used to line electrical furnaces, kilns, and other high-temperature equipment where electrical insulation is required.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords