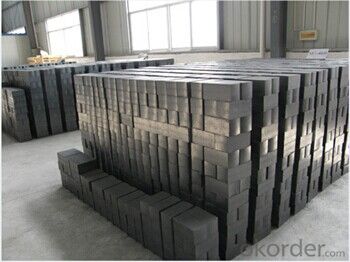

Insulating Fire Brick - Carborundum Refractory Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Passed ISO 9001;

2.57% Alumina content,or as customized;

3. Carborundum Fire Brick is widely used in iron-making.

AL2O3SiCC carborundum fire brick are universal materials for the lining of molten pretreatment equipments of molten iron tank, torpedo car, etc. The products are shaped by machine power by using dense bauxite clinkerand brown fused alumina as base materials and adding high quality SiC fines and high purity glake fraphite. It has the advantages of excellent slag resistance, thermal shock resistance, good resistance to mechanical erosion, abrasion resistance, etc.

Carborundum products belong to high grade refractory material,maximal use temperature is 1500°C,it has excellent thermal conductivity,heat shock stability,high load softening point and very good wear-resisting property,widely used in various industries with special requirement.

Item | Si3N4 bonded SiC brick | Sialon bonded SiC brick | Sialon bonded corundum brick | |

SiC, % ≥ | 72 | 70 | 80 (Al2O3) | |

Si3N4, % ≥ | 20 | 5 (N) | 5 (N) | |

Fe2O3, % ≤ | 0.7 | 0.7 | 0.7 | |

Bulk density g/cm3, ≥ | 2.65 | 2.65 | 3.1 | |

Apparent porosity %,≤ | 16 | 16 | 16 | |

CCS MPa, ≥ | 150 | 150 | 120 | |

MOR Mpa

| Room temp. ≥ | 42 | 42 | 12 |

1400°C×0.5hrs ≥ | 45 | 42 | 20 | |

Refractoriness under load °C ≥ (0.2MPa, 0.6%) | 1700 | 1700 | 1700 | |

Thermal shock resistance, cycles (Water quenching at 1100°C)≥ | 30 | 30 | 30 | |

- Q: Do insulating fire bricks require any special storage conditions?

- There are no specific special storage conditions necessary for insulating fire bricks. These bricks can endure high temperatures and are usually composed of materials like clay or silica that are heat-resistant. Nevertheless, it is advisable to store them in a dry and covered location to prevent moisture absorption or harm. Furthermore, it is crucial to handle these bricks cautiously to avoid breakage or cracks that could impact their insulation properties. Ultimately, as long as the bricks are stored in a dry and safeguarded setting, no particular special storage conditions are needed for insulating fire bricks.

- Q: Can insulating fire bricks be used in high-temperature insulation applications?

- Indeed, high-temperature insulation applications can employ insulating fire bricks. These bricks are specifically engineered to endure and preserve heat in elevated temperatures. With their low thermal conductivity and exceptional insulation capabilities, they prove to be the perfect choice for containing and insulating high temperatures. Their widespread usage can be observed in industries like steel, glass, and ceramics, as well as in furnaces, kilns, and other equipment operating at extreme temperatures. By effectively retaining heat and minimizing energy loss, insulating fire bricks offer a dependable and efficient insulation solution for high-temperature environments.

- Q: Are insulating fire bricks resistant to nitrogen oxides?

- Insulating fire bricks are known for their excellent thermal insulation properties and are commonly used in high-temperature applications such as furnaces, kilns, and industrial boilers. While they are highly resistant to heat and can withstand extreme temperatures, their resistance to nitrogen oxides (NOx) may vary depending on the specific composition and manufacturing process of the bricks. Nitrogen oxides are a group of harmful gases that are produced during combustion processes, particularly at high temperatures. These gases can have detrimental effects on human health and the environment. Although insulating fire bricks have a high melting point and can withstand intense heat, they may not provide sufficient resistance to nitrogen oxides on their own. To enhance the resistance of insulating fire bricks to nitrogen oxides, additional measures and coatings may be required. These could include the use of specialized refractory coatings or the incorporation of specific additives during the manufacturing process to create a more chemically resistant brick. It is important to note that the resistance of insulating fire bricks to nitrogen oxides may also depend on the specific application and operating conditions. Different types of nitrogen oxides, such as nitrogen dioxide (NO2) or nitric oxide (NO), may have different effects on the bricks. Therefore, it is recommended to consult the manufacturer or a specialist in refractory materials to determine the suitability of insulating fire bricks in a specific environment where the presence of nitrogen oxides is a concern.

- Q: Can insulating fire bricks be used in the construction of lime recovery kilns?

- Insulating fire bricks are indeed applicable for the construction of lime recovery kilns. These kilns, utilized in industrial settings, operate at high temperatures to convert limestone into lime via calcination. Specifically designed to endure elevated temperatures and offer exceptional thermal insulation, insulating fire bricks are composed of lightweight refractory materials, such as clay or silica, and possess low thermal conductivity. Within lime recovery kilns, which can reach temperatures ranging from 900 to 1200 degrees Celsius, insulating fire bricks are suitable for lining the kiln's walls, floors, and roofs. Their superior insulating properties effectively diminish heat loss, thereby enhancing energy efficiency by retaining heat within the kiln. Consequently, this results in reduced fuel consumption and cost savings. Furthermore, insulating fire bricks exhibit excellent resistance to thermal shock, a crucial characteristic in the lime recovery process. These kilns undergo repeated cycles of heating and cooling, necessitating bricks capable of withstanding temperature fluctuations without cracking or disintegrating. Ultimately, insulating fire bricks prove to be a fitting choice for lime recovery kilns due to their capacity to withstand high temperatures, provide thermal insulation, and resist thermal shock.

- Q: Can insulating fire bricks be used as a heat shield?

- Insulating fire bricks can serve as an effective heat shield due to their excellent thermal insulation properties. These bricks are specifically designed to block and reflect heat, making them suitable for applications where heat containment or redirection is necessary. Fireplaces, kilns, furnaces, and industrial ovens commonly utilize insulating fire bricks to manage heat. By reducing heat transfer, these bricks create a protective barrier between the intense heat source and the surrounding environment. Moreover, their high melting points and ability to withstand high temperatures make them ideal for use as heat shields. However, it should be noted that the effectiveness of insulating fire bricks as a heat shield may vary depending on the specific requirements and conditions of the application.

- Q: Are insulating fire bricks suitable for use in high-temperature chimneys?

- Yes, insulating fire bricks are suitable for use in high-temperature chimneys. These bricks are specifically designed to withstand extreme temperatures and provide excellent insulation properties. They have a high melting point and low thermal conductivity, which allows them to effectively retain heat and prevent it from escaping through the chimney walls. This helps in maintaining a high temperature inside the chimney, which is crucial for efficient combustion and proper functioning of the chimney. Additionally, insulating fire bricks are lightweight and durable, making them an ideal choice for constructing chimneys that are exposed to high temperatures.

- Q: Can insulating fire bricks be used in the construction of heat exchangers?

- Insulating fire bricks have the capability to be utilized in the construction of heat exchangers. These bricks are specifically designed to possess exceptional thermal insulation properties, thereby rendering them ideal for situations where the maintenance or control of high temperatures is necessary. Heat exchangers, which are devices responsible for the transfer of heat between two or more fluids, require insulation in order to prevent any loss or gain of heat during the process. The incorporation of insulating fire bricks in the construction of heat exchangers aids in the reduction of heat transfer to the surrounding environment, ultimately resulting in enhanced energy efficiency and decreased operational expenses. These bricks are capable of withstanding high temperatures, typically reaching up to 3000°F (1650°C), thus making them suitable for various heat exchanger applications, such as furnaces, boilers, and industrial processes. Moreover, insulating fire bricks possess the additional benefits of being lightweight and having low thermal conductivity. This means that they provide effective insulation while also being less bulky and more cost-effective compared to traditional refractory bricks. Consequently, they are easier to handle and install within heat exchanger systems. In conclusion, the utilization of insulating fire bricks in the construction of heat exchangers offers numerous advantages, including improved thermal insulation, enhanced energy efficiency, and reduced expenses.

- Q: Can insulating fire bricks be used as a backup insulation in refractory linings?

- Yes, insulating fire bricks can be used as a backup insulation in refractory linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them effective in reducing heat transfer in high-temperature applications. Their insulating properties make them ideal for use as a backup insulation layer in refractory linings, helping to further reduce heat loss and improve overall energy efficiency. Additionally, insulating fire bricks are lightweight, which makes them easier to handle and install compared to other refractory materials. However, it is important to consider the specific requirements of the application and consult with a refractory engineer to ensure that insulating fire bricks are suitable for the specific conditions and performance requirements of the refractory lining.

- Q: Can insulating fire bricks be used in biomass power plants?

- Yes, insulating fire bricks can be used in biomass power plants. Insulating fire bricks are designed to withstand high temperatures and provide insulation, making them suitable for various applications in high-temperature environments, including biomass power plants. These power plants generate electricity by burning biomass materials such as wood chips, agricultural waste, and other organic matter. Insulating fire bricks can be used in several areas of a biomass power plant. They can be used to line the combustion chamber, where the biomass is burned to release heat. The insulating properties of these bricks help to contain the heat within the combustion chamber, enhancing the efficiency of the biomass combustion process. Additionally, insulating fire bricks can be used in the construction of the plant's boiler, which is responsible for converting the heat generated by burning biomass into steam. The bricks can be used to line the walls and roof of the boiler, providing thermal insulation and preventing heat loss. This insulation helps to maintain high temperatures inside the boiler, which is crucial for steam generation and subsequent power production. Moreover, insulating fire bricks can be used in the construction of the chimney or flue system of biomass power plants. The bricks can be used to line the interior of the chimney, ensuring that the high temperatures and corrosive gases produced during biomass combustion are contained and safely directed out of the plant. Overall, insulating fire bricks are an excellent choice for biomass power plants due to their ability to withstand high temperatures and provide thermal insulation. Their use in the combustion chamber, boiler, and chimney systems helps to improve the efficiency and safety of biomass power generation.

- Q: Are insulating fire bricks resistant to chemicals?

- Insulating fire bricks, in general, exhibit resistance to chemicals. They are specifically engineered to endure extreme temperatures and possess minimal thermal conductivity, making them a prime selection for chemical-related applications. These bricks are typically composed of ceramic materials, such as alumina, renowned for their exceptional chemical resistance properties. Nonetheless, it is crucial to recognize that the extent of chemical resistance can fluctuate based on the specific variant of insulating fire brick and the chemicals involved. Certain chemicals, particularly those highly corrosive or reactive in nature, may still inflict harm or deterioration on the bricks over time. Thus, seeking detailed information on the chemical resistance capabilities of specific insulating fire bricks from the manufacturer or supplier is highly recommended.

Send your message to us

Insulating Fire Brick - Carborundum Refractory Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords