Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

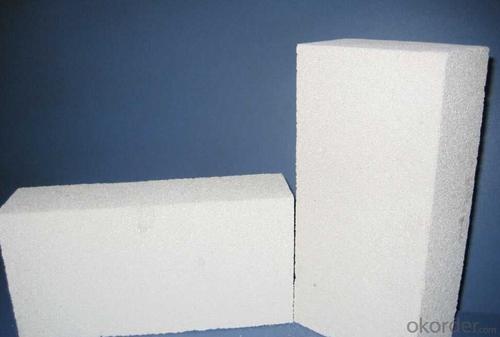

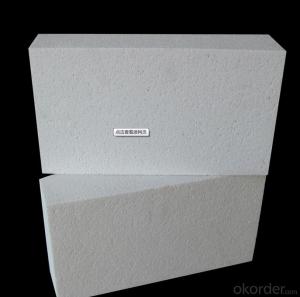

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:

Refractory GJM Mullite Insulation Brick B-4

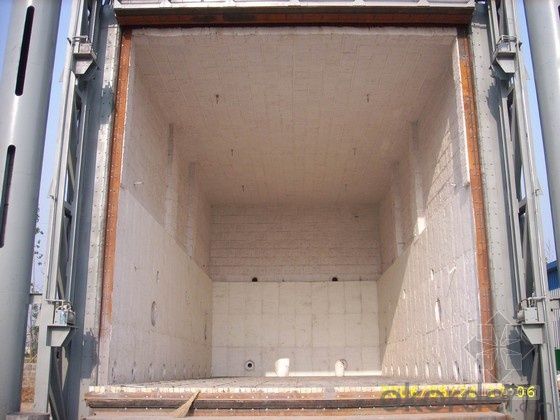

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Refractory GJM Mullite Insulation Brick B-4

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-4

- Q: Can insulating fire bricks be used in the construction of drying ovens?

- Yes, insulating fire bricks can be used in the construction of drying ovens. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain heat and prevent heat loss. This makes them an ideal material for constructing drying ovens, as they can help maintain a constant and controlled temperature within the oven. Additionally, insulating fire bricks are resistant to high temperatures, making them suitable for use in drying ovens where elevated temperatures are required.

- Q: Can insulating fire bricks be used in the construction of thermal insulation roofs?

- Yes, insulating fire bricks can be used in the construction of thermal insulation roofs. These bricks are designed to have high thermal resistance and low thermal conductivity, making them suitable for insulating applications. They can help reduce heat transfer and improve energy efficiency in roofs by providing effective insulation.

- Q: Can insulating fire bricks be used in the construction of smelting ovens?

- Indeed, the utilization of insulating fire bricks in the construction of smelting ovens is indeed possible. These fire bricks are specifically engineered to possess a low thermal conductivity, enabling them to effectively retain heat. This particular characteristic renders them particularly well-suited for applications requiring the consistent maintenance of high temperatures, such as smelting ovens. Smelting ovens serve the purpose of melting and refining various metals and minerals. These procedures entail the utilization of exceedingly high temperatures, making it crucial to minimize heat dissipation in order to ensure efficient and effective smelting. By providing exceptional insulation and reducing heat dissipation, insulating fire bricks can contribute to the achievement of this objective. Insulating fire bricks are manufactured using lightweight materials, including ceramic fibers or expanded clay, which are renowned for their superior insulating properties. These fire bricks are capable of withstanding temperatures of up to 3000°F (1650°C), rendering them suitable for the intense heat generated within smelting ovens. Moreover, insulating fire bricks demonstrate resistance against thermal shock, enabling them to endure rapid temperature fluctuations without suffering from cracks or breakages. This quality is of utmost importance in smelting processes, which frequently involve cycles of heating and cooling. Furthermore, insulating fire bricks are highly malleable and can be easily cut or shaped to accommodate specific dimensions or designs. This inherent flexibility renders them highly adaptable for the construction of smelting ovens of varying shapes and sizes. To summarize, the implementation of insulating fire bricks in the construction of smelting ovens is an exceptional choice due to their low thermal conductivity, high resistance to extreme temperatures, ability to withstand thermal shock, and ease of customization. These fire bricks effectively maintain high temperatures, minimize heat dissipation, and ensure the efficiency of smelting processes.

- Q: What are the main components of insulating fire bricks?

- The main components of insulating fire bricks are typically a combination of alumina, silica, and various lightweight additives. Alumina (Al2O3) provides high temperature stability and resistance to thermal shock, making it a key component in insulating fire bricks. Silica (SiO2) helps to improve the refractory properties and insulation capabilities of the bricks. Additionally, lightweight additives such as vermiculite or perlite are often included to increase the insulating properties of the bricks. These components work together to create a material with excellent thermal insulation, low thermal conductivity, and high resistance to heat.

- Q: How to reinforce a porous brick foundation?

- Pressure grouting method is changed from independent foundation to strip foundation, from strip foundation to raft foundation and pile foundation, from brick strip foundation to concrete strip foundation.

- Q: The insulation layer destroyed after use of cement paste and tiling

- Put on the insulating layer and paste it with cement.Some students worry about the insulation layer and the wall adhesive strength is not enough, do not worry about, now developers are building exterior insulation and then on top of the tiling. Because after finishing the insulation layer, the contractor should check the construction to do a pullout test, the purpose is to prevent the strength can not meet the requirements.

- Q: Can insulating fire bricks be used in pottery kilns?

- Pottery kilns can indeed utilize insulating fire bricks. These bricks, also referred to as refractory bricks, possess a specialized design that enables them to endure high temperatures and provide insulation to retain heat within the kilns. Alumina, silica, and other refractory materials are employed in the creation of these bricks, as they possess exceptional thermal resistance properties. The utilization of insulating fire bricks in pottery kilns aids in the maintenance of a consistent temperature, reduction of heat loss, and ensures efficient firing of clay and glazes. Moreover, these bricks contribute to the elongation of the kiln's lifespan by safeguarding the interior walls from extreme temperatures. Consequently, insulating fire bricks represent an ideal choice for pottery kilns and are extensively employed in the pottery industry.

- Q: Can insulating fire bricks be used in chimneys and flues?

- Yes, insulating fire bricks can be used in chimneys and flues. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for use in areas where heat needs to be contained or controlled, such as chimneys and flues.

- Q: Can insulating fire bricks be used in the construction of combustion chambers for rocket engines?

- Yes, insulating fire bricks can be used in the construction of combustion chambers for rocket engines. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in the extreme conditions of rocket engine combustion chambers. Their ability to retain heat while minimizing heat transfer to the surrounding structure is crucial for ensuring efficient and safe operation of the engine.

- Q: Can insulating fire bricks be used for insulation in boilers?

- Certainly, insulation in boilers can make use of insulating fire bricks. These bricks are specially engineered to endure extreme temperatures and offer exceptional thermal insulation. Their thermal conductivity is minimal, resulting in a significant decrease in heat dissipation and an enhancement in the energy efficacy of boilers. Moreover, insulating fire bricks are lightweight and simple to install, rendering them a favored option for boiler insulation. They aid in preserving elevated temperatures within the boiler, facilitating efficient combustion and heat transfer, while simultaneously shielding the outer framework from excessive heat. All in all, insulating fire bricks are a dependable and efficient alternative for boiler insulation.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords